Strong Carbon Nanotube Bond to Metal Discovered

Creating a decent bond between metal and nanomaterials has unleashed more nanotechnology potential for manufacturing.

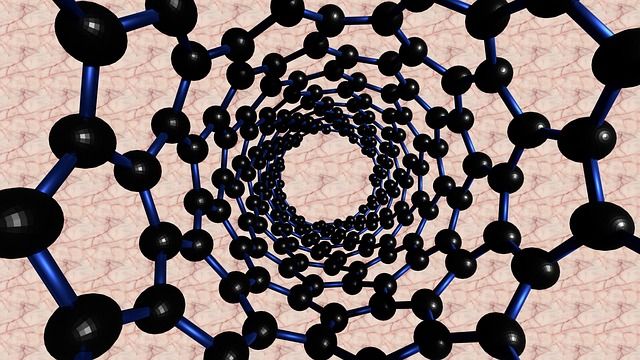

Nanotechnology is still enjoying a vast array of discoveries. While the first nanomaterials were created in a lab less than forty years ago, they have already permeated through every industry to form developments such as improved plastics, better insulators, fade resistant coatings, colour changing textiles, and super strong, yet lightweight composites.

They have achieved this because nanomaterials, such as carbon nanotubes, are the strongest materials known to science, while also being electrically and thermally conductive, extremely light weight, and excellent mixers with a wide variety of other raw materials. Polymers, for example, can easily be blended with nanomaterials to impart desired properties without losing the plastic’s intrinsic, natural advantages.

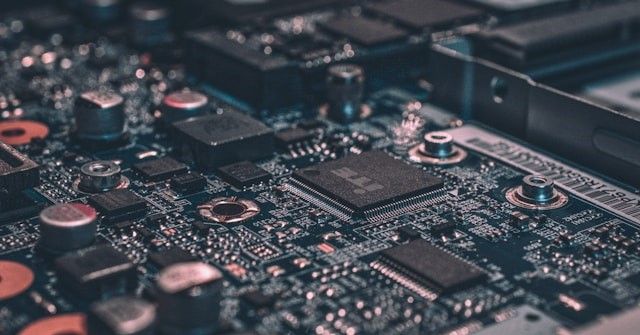

One of their greatest failings, however, is the difficulty in attaching them to metal surfaces. This has meant that their true potential in the field of electronics has yet to be met, as they do not form sturdy connections with devices such as metal sensors or transistors.

“Unfortunately, in practice,” reports a recent study in the journal Nanoscale Advances, “the electrical conductivity of most CNTs and their assemblies has fallen short of expectations. One reason for this poor performance is that electrical resistance develops at the interface between carbon nanomaterials and metal surfaces when traditional metal–metal type contacts are employed.”

It is a situation which Prof. Noe T. Alvarez, who led the discovery, likens to sticking ‘wet spaghetti’ to a saucepan - it sticks, but not for very long.

“We want our experiments to be reproducible and consistent, but that’s not easily possible with nanotubes because we can’t control how well they’re connected to metal surfaces,” he says. “There is no robust connection. Nothing is really holding the nanotubes to the surface.”

This issue may now have been resolved, as nanomaterial researchers from the University of Cincinnati have collaborated with a team from Texas A&M University to create a durable, sufficiently strong and electrically conductive chemical bond between carbon nanotubes and copper, aluminium, gold, and other metal surfaces.

It is a discovery which may lead to improved manufacturing in sectors such as aviation, energy storage, microelectronics, and maybe one day, even a space elevator.

As the University of Cincinnati press release describes, “Alvarez and his co-authors discovered through computational calculations that carbon atoms in the organic link actually bond with two copper atoms, creating an especially strong bond.”

“That explains why our nanotubes once they’re chemically connected stay connected,” explains Alvarez. “Carbon bonds are the strongest bonds. They’re covalent bonds. That’s why diamond is the hardest material because they are carbon-carbon bonds.”

Yet, carbon nanotubes are even stronger than diamonds because they contain conjugated double-bonded carbon atoms instead of just single bonds. Furthermore, they hold sought-after qualities which are in high demand in the manufacturing sector.

“Nanotubes are fairly inert. They’re very stable. You can conjugate them without breaking their bonds. Semiconducting nanotubes also have fluorescence properties — they can generate light,” says Alvarez. “So, the list of applications goes on and on.”

One key application could be their use in improving battery technology.

“Now that we can bond the carbon nanotubes to a current collector or metal probe, we can make very stable electrodes for supercapacitors,” says the study’s lead author Chaminda Nawarathne.

Yet this breakthrough is clearly just the tip of the iceberg. Now that nanotubes can be solidly fixed to metals while still maintaining a good electrical connection, then the field of electronics can more fully embrace the nanotechnological revolution. From smaller electronic devices, wearable technology, and the expansion of the Internet of Things, this discovery has opened the door for other researchers to find practical applications.

From there, manufactured products can truly benefit from the nanotechnology revolution. Even in connection with metal surfaces.

Photo credit: Wirestock on Freepik, Dean Simmone from Pixabay, Alexandre Debieve on Unsplash, & Michael Hiraeth