Nanocoating Combats Bacteria on Farm and Food Processing Steel

Nanomaterial researchers have developed a galvanised steel coating to fight bacteria and microbes on farm and food processing equipment.

Due to its affordability and durability, galvanised steel is frequently used in the food processing industry and agricultural sector. However, scientific evidence has proven that food which comes into contact with these surfaces can be contaminated with microorganisms.

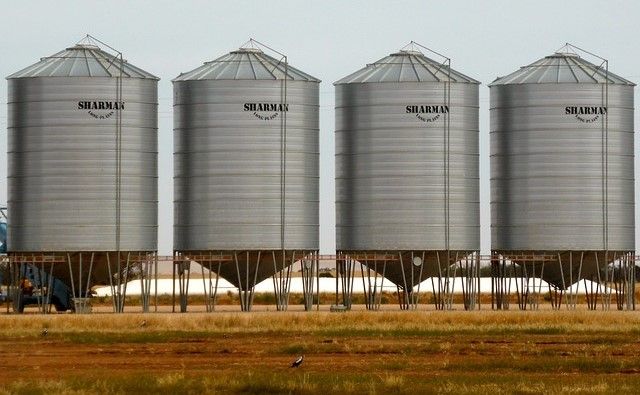

The issue of grain storage, for example, has been widely studied, with research finding frequent fungal problems in grain silos made of galvanised steel, damaging both food and promoting additional corrosion of expensive facilities.

This costly issue may now be solved through the intelligent application of nanotechnology.

With a diameter as small as 100,000th the thickness of a human hair, nanomaterials are able to alter a surface at the atomic scale. In doing so, nanotechnology scientists have been able to create a nanocoating for galvanized steel which prevents bacteria from attaching to the surface of food containers and machinery.

According to the research conducted at Texas A&M University by Dr Mustafa Akbulut, a professor of chemical engineering, and Dr Luis Cisneros-Zevallos, a professor of horticultural science, the nanomaterial coating can reduce the formation of rust by at least 70 percent.

Key to the discovery is how the nanomaterial coating gives a surface superhydrophobicity and antifouling capabilities, successfully preventing bacteria and fungal spores from adhering.

The study has now been published in the peer-reviewed Journal of Food Engineering, where the researchers explain how their nanomaterial coating, “… exhibited antifouling effect against pathogenic fungi Aspergillus niger.” Adding that, “With the use of coating, adhesion of Salmonella and Listeria was reduced by >99.5%. [With] coated surfaces [experiencing a] significantly reduced corrosion rate induced by microorganisms.”

“This material is more durable and doesn’t experience corrosion,” explains Akbulut. “The surface itself can repel the bacteria so it doesn’t get germs stuck on it. Normal steel tends to collect pathogens and microorganisms, but the coated steel is overcoming that issue. These are the main benefits of this technology.”

But this nanomaterial coating does more than just prevent microbes from attaching to steel, it also reduces the amount of soil that collects on machinery or storage containers.

“Many of the food-produced commodities come to the industrial setting in some sort of soil, debris or mud,” notes Akbulut. “So, even if the produce is washed, these commodities can cause contamination. With this technology, we are reducing mud-related contamination.”

“This will have an impact because the people that consume fruits and vegetables trust that they’re buying something safe, and it will not affect their health,” adds Cisneros-Zevallos. “Right now, the industry does their best to reduce those risks, but you will hear about outbreaks of these contaminations and people getting sick. There are sometimes reported deaths because of these events.”

When used as a feedstock, nanomaterials are already used to improve coatings by providing beneficial qualities, such as UV protection, superior impact strength, crack resistance, and thermal and electrical conductivity. These technological advances have been applied to furniture coatings, railcars in the mining industry, buildings, epoxy floor resins, aircraft, and in many other sectors.

But now, the food processing and farming industries can also begin to benefit from nanomaterial coatings.

“With this research, we are ensuring that the technological developments from other fields are being pursued and implemented in agriculture,” Cisneros-Zevallos said. “The agricultural field is catching up with other technologies. This coating directly impacts our daily life and the food we’re trying to make safer.”

To learn more about nanomaterial coatings and protective measures for polymers and rubbers, visit POLYMER NANO CENTRUM.

Photo credit: jaymethunt from Pixabay, alexanderlittlewolf on Freepik, Siggy Nowak, Wikiimages, & alexanderlittlewolf