An Introduction to Nanomaterials as a Feedstock for Polymers

A tale of tiny particles and how they have matched up with polymer manufacturing.

The prefix ‘nano’ derives from the Greek νάνος,meaning ‘dwarf’. In the Latin alphabet this is written as nanos.

Nanomaterials are therefore tiny particles with a size between 1 and 100 nanometres (nm). To help visualise something as small as 1 nm (one billionth of a meter), think of a human hair which measures about 90,000 nm wide or a sheet of paper which is about 100,000 nm thick.

By manipulating materials at the nanoscopic scale, they can have different chemical and physical properties depending on their size and/or orientation.

While nanomaterials have always been present in nature, for example in the subcellular machinery of every cell, the dirt-repelling surfaces of lotus flowers, and the inorganic nanomaterials spewed by volcanoes, they did not truly come to scientific interest until 1959. This was when the American physicist and Nobel Prize laureate Richard Feynman, invited his students to study the field of nanotechnology in his famous lecture “There's Plenty of Room at the Bottom”. Here he suggested that materials could be controlled at the nanoscale and predicted a future where it would be possible to store the entire 24 volumes of the Encyclopedia Britannica on the head of a pin.

The Nobel Prizes of 1996, 2016, and 2019 in chemistry and 2010 prize in physics all concerned nanomaterials and opened the way towards their practical application.

Today, nanotechnology has thousands of applications in manufacturing, providing additional properties and improved performance. Items such as scratch-resistant eyeglasses, crack-resistant paints, anti-graffiti coatings for walls, transparent sunscreens, stain-repellent fabrics, self-cleaning windows, and ceramic coatings for solar cells are now all made with nanoparticles.

Nanomaterials are an ideal industrial raw material largely due to their tiny size.

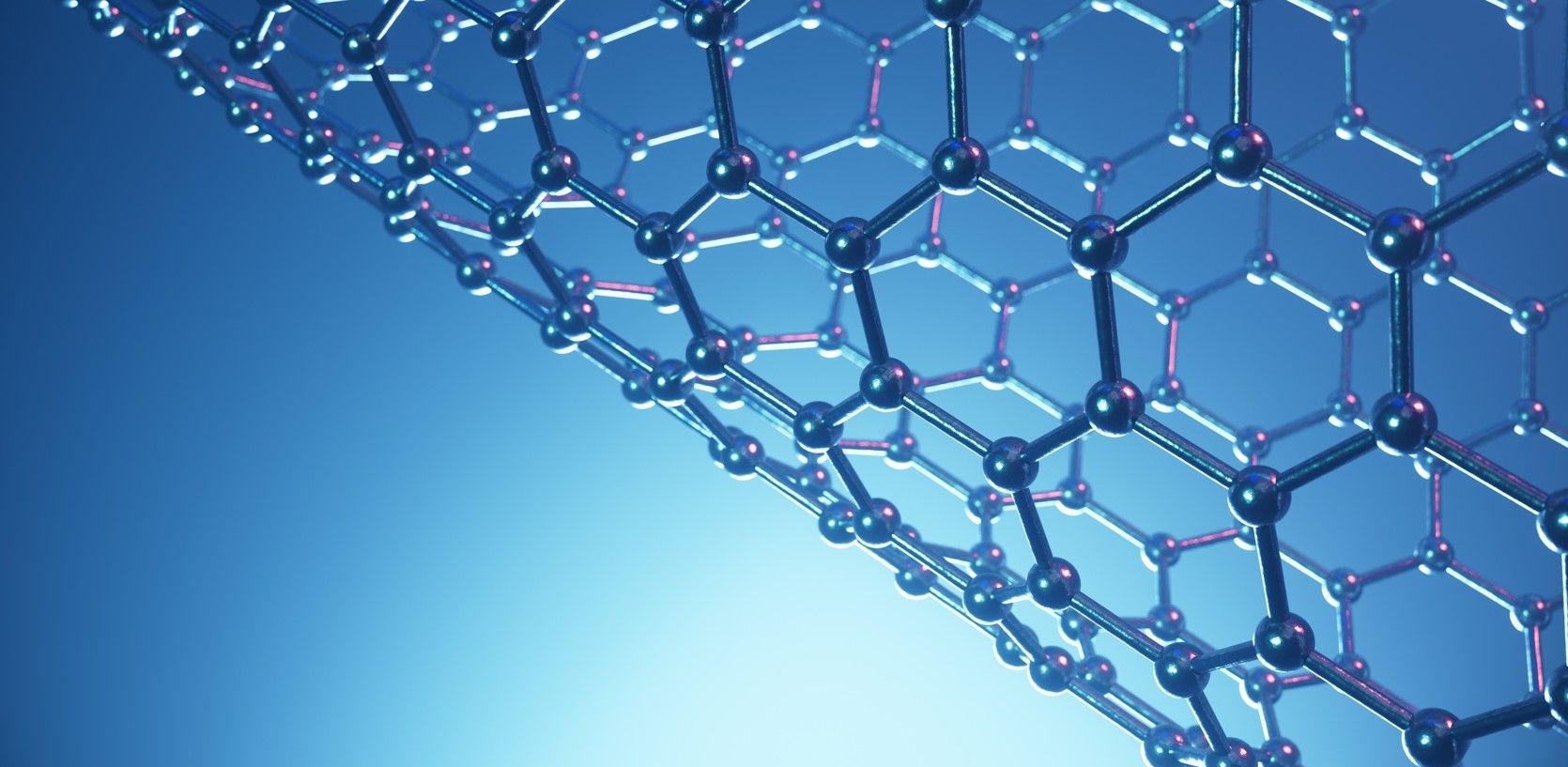

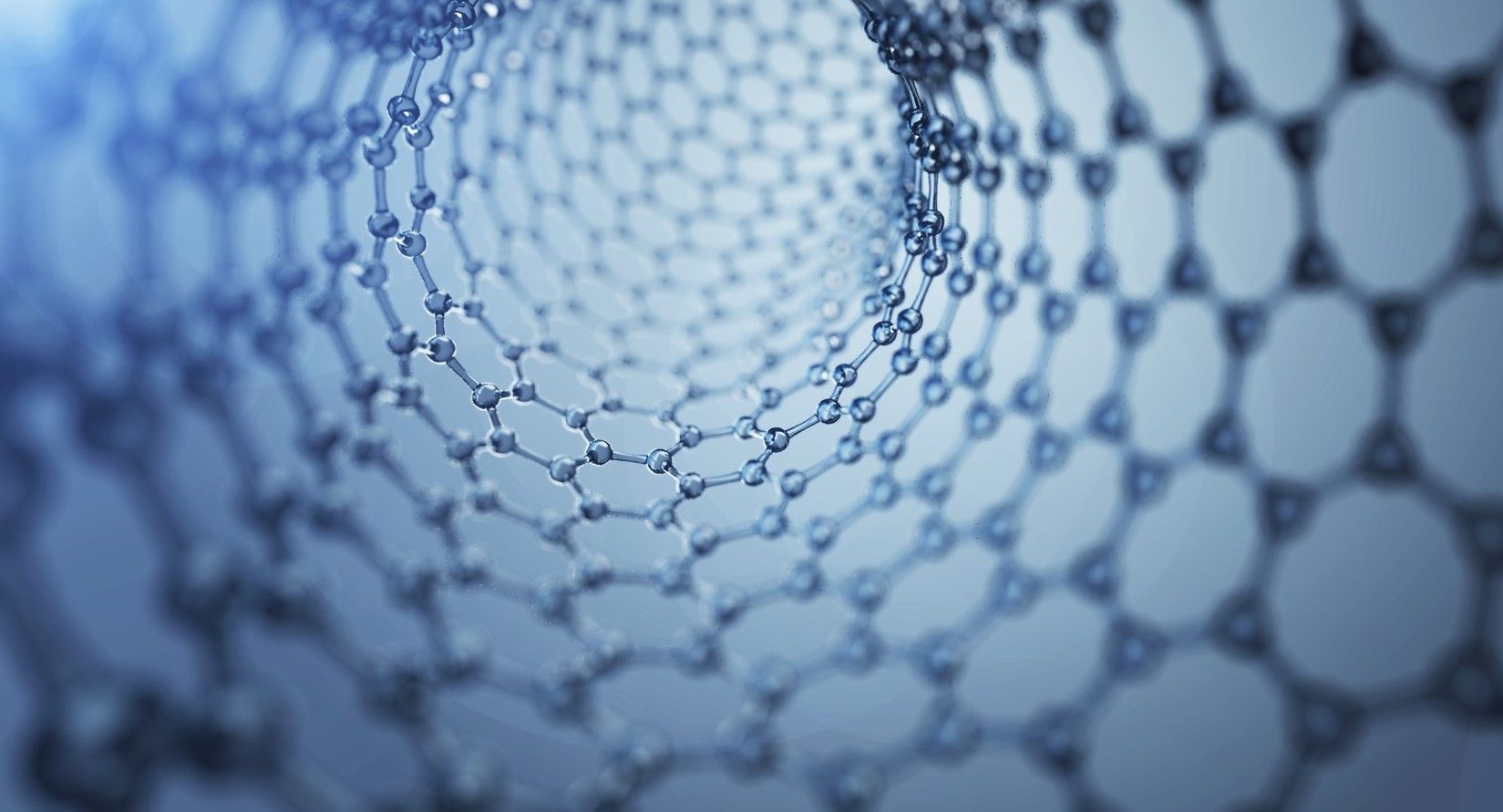

A carbon nanotube typically measures just 0.000050 mm in diameter, giving it a huge weight to surface area ratio. This means that when blended with conventional feedstocks, it can impart its properties (such as high strength, electrical conductivity, chemical resistance, thermal conductivity etc.) into the new composite while still maintaining original feedstock values.

One company has taken these nanotechnology advances to improve both the fabrication process and final product in raw materials is the Czech-based Polymer Nano Centrum.

By creating a material from a mixture of thermoplastics and nanomaterials Polymer Nano Centrum (who sponsor this webpage) have developed a technology which is 25-30% more efficient across a whole range of properties, including:

· Mechanical properties

· Electromagnetic properties

· Electrostatic properties

· Higher chemical resistance

By cooperating with manufacturers, Polymer Nano Centrum is able to apply these properties into finished goods, lowering raw material costs (for example by replacing bulk quantities of conventional inputs with lower quantities of nanomaterials), reducing production times (for example through quicker setting polymers), and/or providing unique selling points.

Polymer Nano Centrum’s experts offer a full, professional consultation and implementation throughout all stages of the production cycle.

For more information, please contact info@polymernanocentrum.cz, phone +420 233 371 850 or visit Polymer Nano Centrum.

Photo credit: Polymer Nano Centrum, Macrovektor on Freepik, & Freepik