Turning Graphene into a Printable Ink for Manufacturing

How a game-changing discovery has unlocked nanomaterial’s potential for 3D printing and manufacturing.

Graphene, the ultra-thin material celebrated for its strength, conductivity, and flexibility, has long been hailed as a game-changer in advanced manufacturing. However, the major hurdle of how to integrate graphene into raw materials has prevented its widespread adoption. Due to its tendency to clump together, graphene has been notoriously difficult to mix into inks and coatings without losing its remarkable properties.

Now, researchers have made a breakthrough by discovering a method to transform graphene into a stable, printable ink. This innovation paves the way for a new era of high-performance electronics, flexible circuits, and ultra-lightweight materials that can be produced with standard 3D printing techniques. By overcoming the challenge of dispersion, this discovery could bring graphene out of the lab and into mainstream manufacturing, revolutionizing industries from automotive, electronics, aerospace, and even environmental clean-up.

Like graphene, carbon nanotubes and other nanomaterials initially faced significant challenges in practical applications due to their tendency to cluster together. This agglomeration limited their ability to be evenly distributed in liquids and solids, reducing their effectiveness in enhancing materials. However, researchers have since developed advanced dispersion techniques, such as surface functionalization or surfactant and solvent-assisted methods which allow these nanomaterials to blend seamlessly into polymers, plastics, coatings, and epoxy resins. This means that they are now widely used to improve strength, conductivity, and durability in a range of raw materials, such as epoxy resins and polycarbonate sheeting.

Today, companies like NANO CHEMI GROUP have developed a range of off-the-shelf raw materials which can provide manufacturers with the ability to provide their products with the benefits of nanotechnology. Other companies, such as POLYMER NANO CENTRUM, allow for a more bespoke method of including nanomaterials into a product. The company, which hosts this webpage, are specialists in the development of nanotechnology solutions for manufacturing. Since 2016, they have been providing manufacturers with coatings, raw materials, and tailormade solutions with nanomaterials.

Contact POLYMER NANO CENTRUM today, to find out how its expertise and state-of-the-art research centre can reduce input costs or provide unique selling points.

Like other carbon nanomaterials, graphene is well known for its strength, electrical conductivity, and thermal properties, but it is typically synthesized in a powder form which is difficult to work with and mix into other materials. This has limited its use in the manufacturing sector and has left many of its advantages as a raw material remaining in the laboratory.

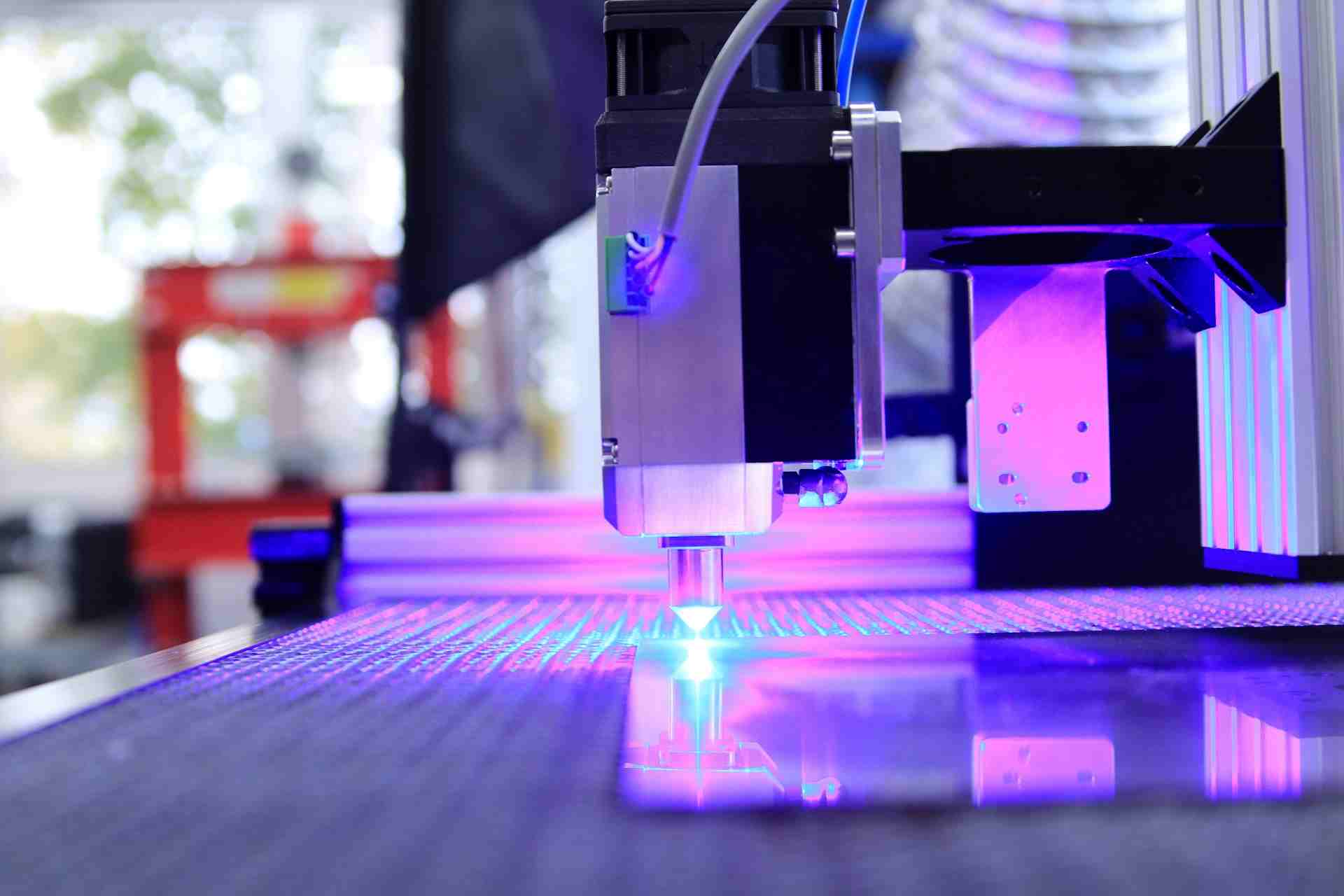

Now a breakthrough has been made to include the 2D material into the world’s first all-graphene ink by creating graphene nanosheets that disperse in water while remaining conductive.

Related articles: Carbon Nanomaterials Proven 100% Recyclable or Nanotechnology Provides Custom-Made Raw Materials

The discovery was made by a collaboration of researchers from the University of Calgary, University of British Columbia, the University of Waterloo in Canada, and Aalto University in Finland where they, developed a water-based, functional ink made with graphene which can be used with 3D printers. This could enable the manufacture of items such as 3D-printed vehicle parts which are lighter (saving fuel) while boosting durability. Other items which could be 3D printed with the nanomaterial ink are filters for water purification and desalination or consumer electronics, such as smartwatches, fitness bands, and glucose monitoring devices for diabetics.

“Shaping graphitic materials into complex geometries for advanced applications has long been a critical challenge that has limited their widespread adoption,” explains Prof. Milad Kamkar from the Department of Chemical Engineering at Waterloo. “With our proposed methods, we can 3D-print graphene into any shape.”

The nanomaterial ink was made through a two-step electrochemical process that is well-suited to upscaling to an industrial level. This is because of, according to the press release, “A specially designed step called intercalation, which involves the insertion of a molecule into layered graphite, allows for continuous production of the graphene nanosheets in water.”

The study has now been published in the Journal of Materials Chemistry A, where the researchers explain how suitable their nanomaterial ink is suitable for the manufacturing sector, stating that, “… the fabrication process aligns with industrial demands for energy-efficient production processes and high output rates, marking a significant advancement in the field of materials science and offering promising prospects for applying graphene-based inks in advanced manufacturing technologies.”

“Our modern technological advancements have come at the cost of new environmental challenges,” notes Kamkar. “To survive and address these challenges, we must develop new materials that are more effective than those currently available. This can only be achieved by controlling and fine-tuning material properties across multiple scales, from the molecular and nano levels to the macro scale.”

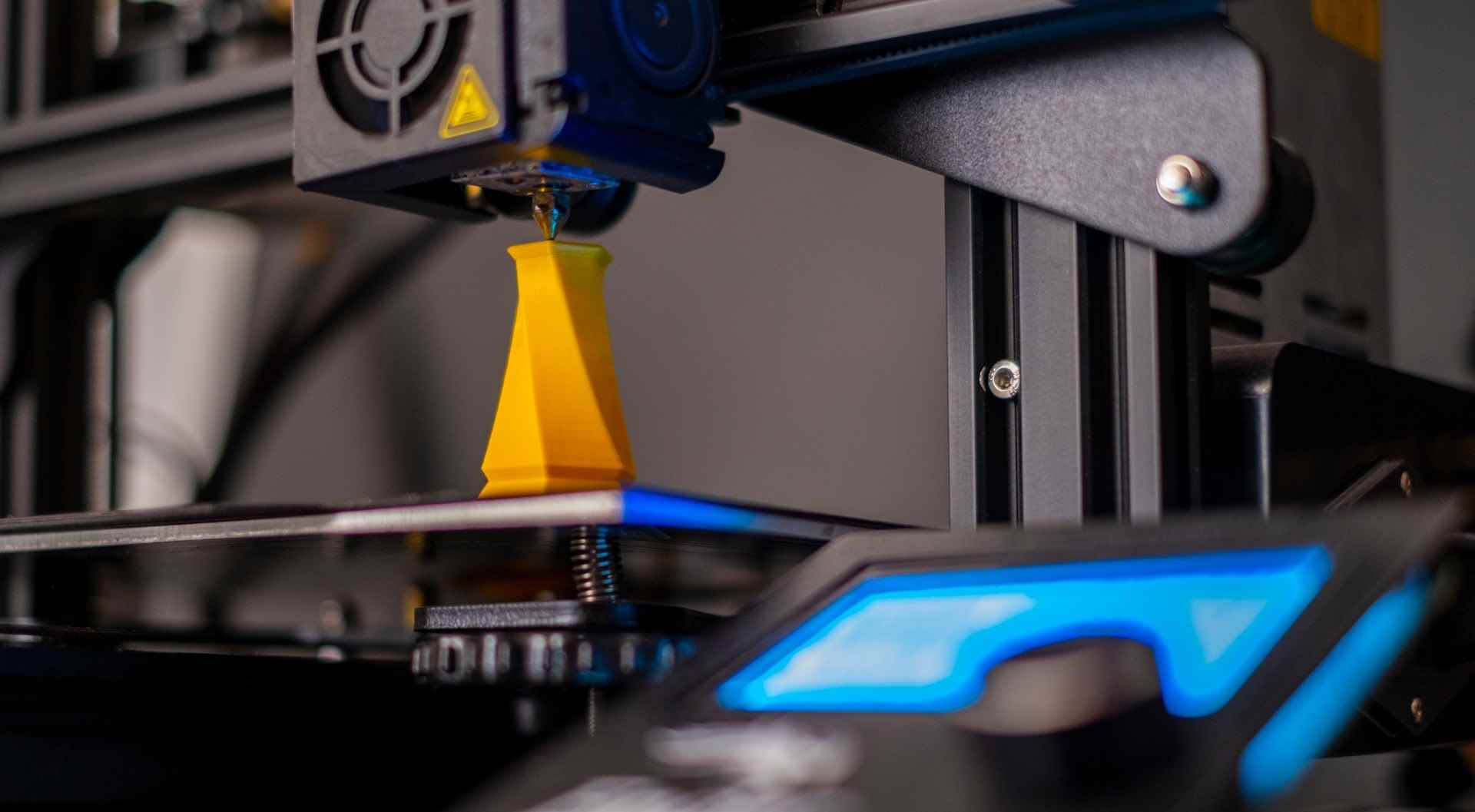

The development of graphene-based 3D printing ink marks a significant step forward in additive manufacturing, combining the exceptional mechanical, electrical, and thermal properties of graphene with the versatility of 3D printing. This innovation is poised to revolutionize industries such as aerospace, electronics, biomedical engineering, and energy storage, enabling the creation of lightweight yet strong components, highly conductive circuits, and advanced medical implants.

As research continues to refine ink formulations and printing techniques, the scalability and commercial adoption of graphene-enhanced 3D printing will likely accelerate. Overcoming challenges such as cost, material consistency, and large-scale production will be key to unlocking its full potential. With further advances, graphene-based 3D printing could become a cornerstone of next-generation manufacturing, enabling more efficient, sustainable, and high-performance materials for a wide range of industrial applications.

Photo credit: Osman Tahla Dikyar on Unsplash, Opt lasers, Freepik, & Wirestock on Freepik