Why the Best Jet Fighter in the World Uses Nanotechnology

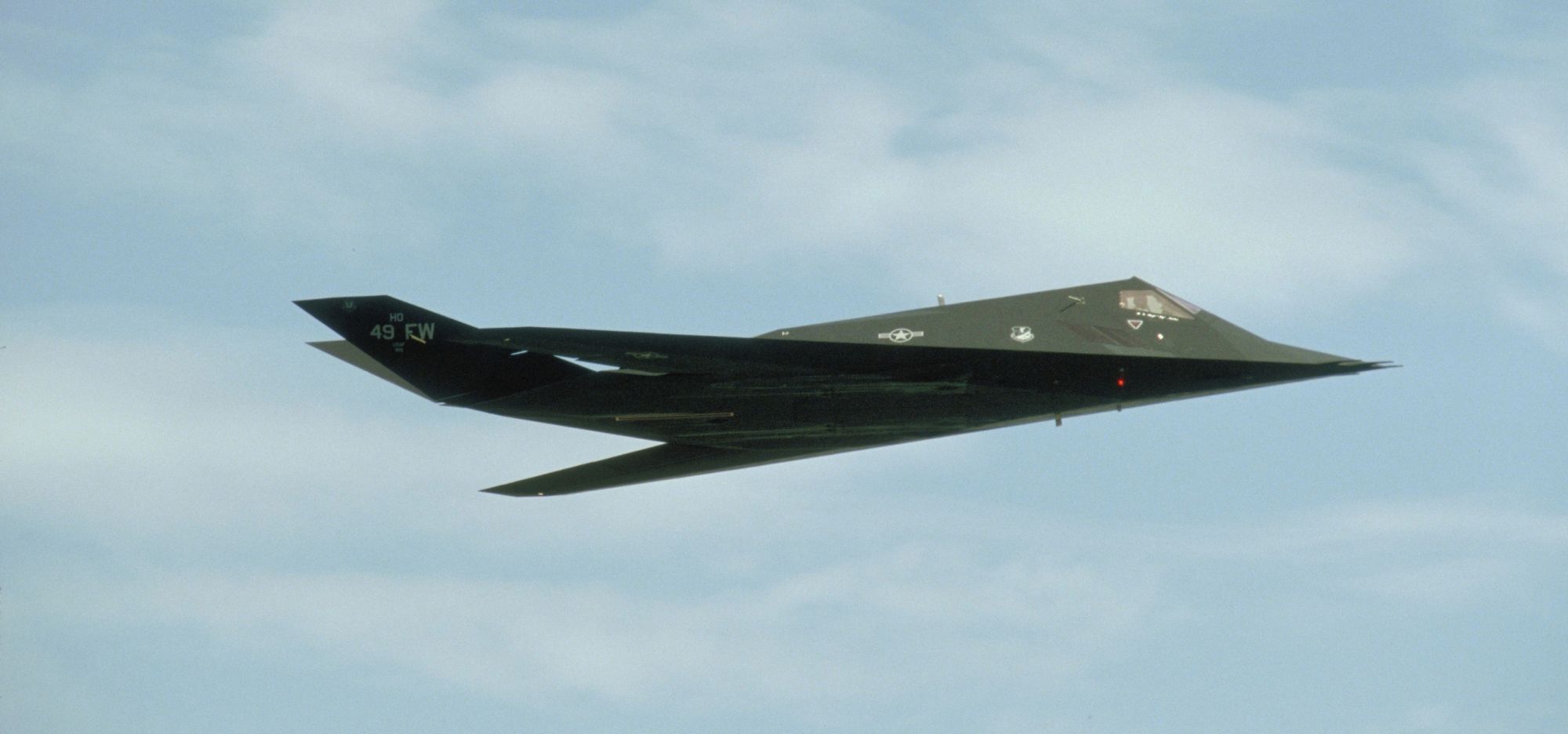

Faster, more agile, more powerful, but most importantly hidden. Behind the design and raw materials of the F-35.

The F-35 is the most advanced plane ever made.

It is a marvel of modern engineering that has created a Vertical Take Off and Landing aircraft that can outperform any of its competitors.

It achieves this through a range of highly advanced systems, including;

· Hive Thinking Capability: an information and communications gateway to share its operational picture with ground, sea, and air assets.

· Weapons: both the internal armoury for use in stealth configuration or the external weapons array allow for success in dogfights or for raids on heavily protected, strategic ground targets.

· Speed and Distance: even with a full complement of internal weapons and fuel the plane can reach speeds of Mach 1.6 and operate as a long range, supersonic fighter.

· Helmet & Pilot Interface: The pilot has a first-of-its-kind interface that projects flight data onto the visor screen. A visor that also allows for night vision and thermal imaging.

· Advanced Electronic Warfare Capabilities: the plane’s onboard systems are able to locate and track enemy forces, jam radars, and disrupts attacks.

But above all, what makes the F-35 such a formidable aircraft is its ability to lower the chance of detection by radar, known in military circles as Low Observable Stealth.

What is Low Observable Stealth?

The F-35 was designed with stealth in mind from day one, giving it an unmatched ability to evade enemy detection and enter contested airspace.

This it achieves in three major design advances.

1. Computer design and surface angles

America’s first ‘stealth’ aircraft was the F-117 which was designed with a diamond like faceted surface to deflect radar waves.

Radar reflects best off a long, flat surface directly facing the radar transmitter. By placing angles on the F-117, the incoming radar was reflected away at different angles, and not directly back at the source. This makes radar detection difficult, but not impossible.

However, this revolutionary design created a plane with minimal aerodynamics suitable for a jet fighter.

The F-35 has advanced the concept by using a computer to design a surface which is smooth enough to allow for smooth airflow, but still has a diamond faceted surface. The radar reflecting angles are present but are too small to see. This means that the plane is still able to reflect radar signals, but can also have an aerodynamic form for easier, more efficient, and faster flying.

2. Onboard software

The F-35’s onboard computers can track ground radar stations and adjust the flight path to minimise radar reflection.

If a radar station is detected, the pilot will be informed. As the pilot then turns the plane, banking left or right, the onboard computer will only allow the pilot to turn the jet in a way that the incoming radar will be reflected away from the radar receiving stations.

3. Radar absorbing coating.

Both the F-22 and the F-117 had stealth capabilities and both used thin coatings that were designed to absorb radar signals. However, these coatings were very fragile and required lots of maintenance.

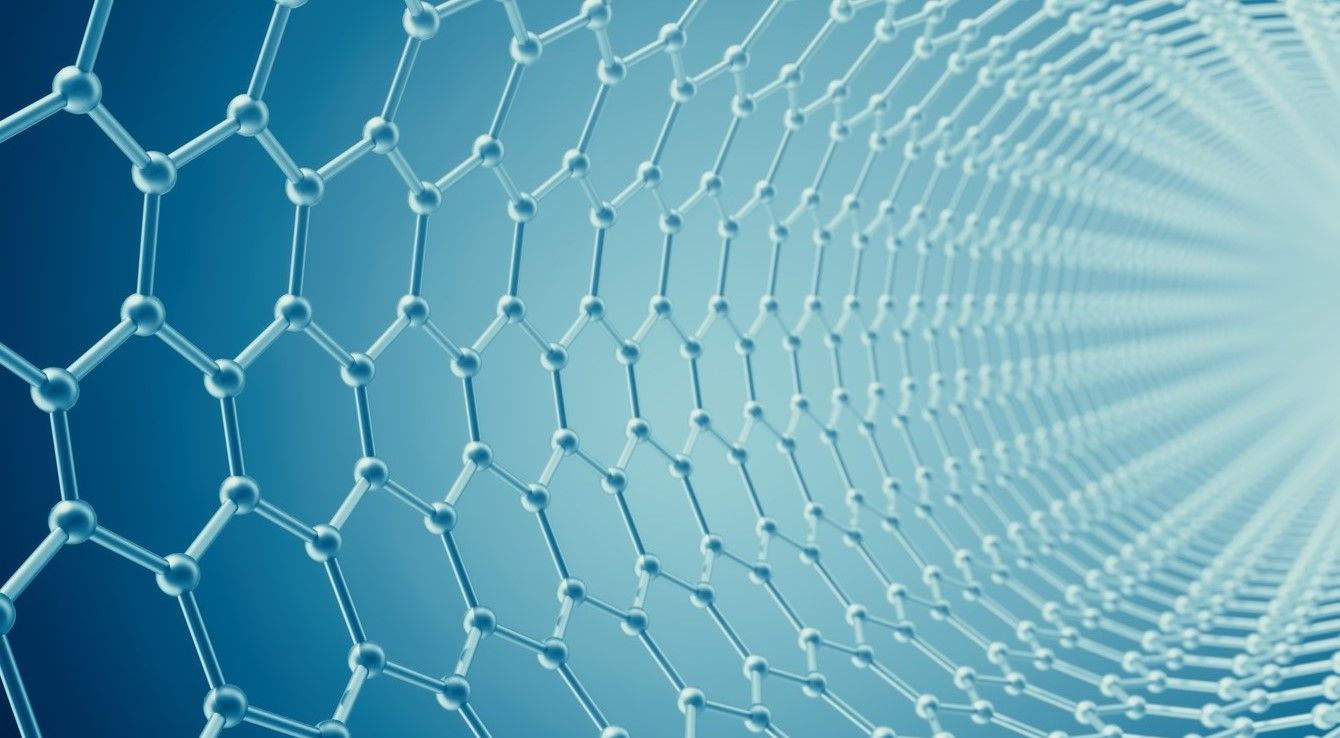

The F-35 has solved this issue with a stealth coating which is not an actual coating, but a composite multi-layered material infused with carbon nanotubes called “fiber-mat”. Unlike older-generation jets, this breakthrough technology from Lockheed Martin is baked into the air frame, giving it exceptional strength and a lifespan that matches the air frame itself.

While the details of how the fiber-mat is made are a closely guarded secret, it is likely a composite of carbon fibre, thermosetting bismaleimide (BMI), epoxy, and of course, carbon nanotubes.

How this differs from standard carbon fibre is unknown, however, it is possible that the carbon is doped (to add impurities) in a way that modifies how it interacts with the electric and magnetic fields of incoming radar energy. In addition, because carbon composites are typically formed by applying layers upon layers of carbon and matrix (epoxy or BMI resin), the engineers can adjust the density and doping of carbon in each layer, so that each works against a specific radar frequency.

The radar waves can even rebound inside the material, cancelling each other out when they reflect off some inner layer at a precise depth in the skin.

Through this method the coating can absorb radar from 0.1 megahertz through to 60 gigahertz - an incredibly wide range of frequencies that includes frequencies used by Russian systems, such as the S-400 surface to air missile.

According to experts at Aviation Week, the skin of the F-35 is finished with a top coating of polyurethane-based radar absorbent material, which helps to reduce drag and limits infrared emissions. This is seen as a dark grey paint which covers a mint-green primer.

Carbon nanotubes are an ideal material for this requirement, as they are very strong, durable, lightweight, and have easily adjustable electro-magnetic conductivity. They are also cylindrical, making them an ideal shape to scatter radar waves in all directions.

At the atomic scale, if the radar wavelength is at least 1/10thof the carbon nanotubes circumference, the wave can actually travel around the outside of the tube and away again.

In fact, during its development in 2010, Tom Burbage, executive vice president of F-35 program integration for Lockheed Martin described the application of nanotechnology in the fiber-mat as, “the single, biggest technological breakthrough we've had on this program.” Adding how it, “makes this airplane extremely rugged. You literally have to damage the airplane to reduce the [radar] signature.”

Lockheed even states that as the coating wears down its stealth capability actually improves.

The final result for this nanotechnology is priceless when fighting for air superiority, but comes with a big pre-war price tag.

Recent documents from Congress confirm that the 2022 Defense Authorization Bill allowed for $8.7 billion to procure 85 aircraft. This includes 48 F-35As with conventional take-off and landing, 17 short take-off and vertical-landing F-35Bs, and 20 carrier-based F-35Cs with catapult launch systems.

However, current plans from the Department of Defense call for the manufacture of 2,456 aircraft, with an additional few hundred expected to be sold to allies, including the eight nations which have been cost-sharing partners in the plane’s development.

Photo credit: E. W. Forbess from Pixabay, Military Material, Military Material, Miguel Á. Padriñán, & Freepix & Freeimages