The 101 on Nanoclay-Enhanced Polymers

How plastic packaging barrier properties can be improved with the smart inclusion of nanoclay technology.

In the world of food and pharmaceutical packaging, one property reigns supreme: protection.

Whether it’s oxygen-sensitive food or moisture-sensitive medication, the longevity and safety of a product often depends on the barrier properties of its packaging. Traditional polymer films like polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) have many advantages—flexibility, cost-effectiveness, and ease of processing—but often fall short in blocking gases and vapours.

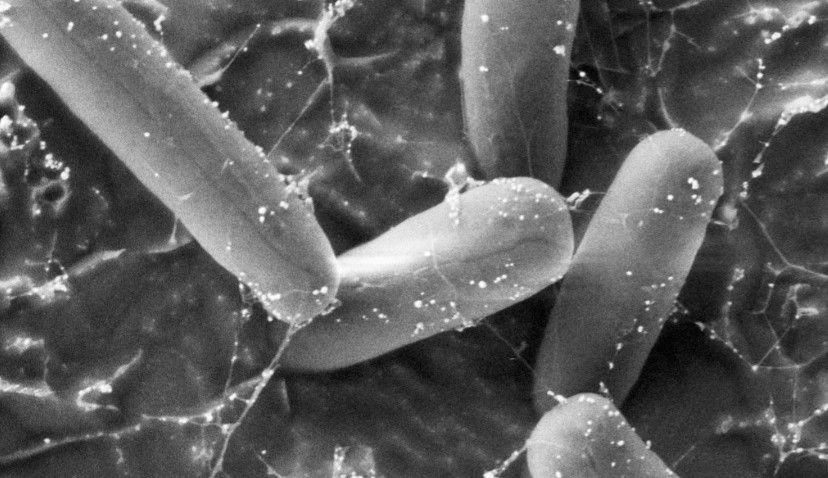

Enter nanoclays: a class of layered silicate materials which when added to polymers dramatically improve their barrier performance. While the application of nanotechnology is highly expert and precise, at their most fundamental, nanomaterials gain advantages as feedstocks through very simple science.

Simply put, because nanomaterials are so tiny, they fit well into plastic and other materials, helping make everyday items—like food wrappers, medicine packs, and shampoo bottles—work better and last longer.

Nanoclay particles are incredibly small—about 1 nanometre thick and up to several hundred nanometres wide. To put that in perspective:

· A nanometre is one-billionth of a metre.

· A human hair is around 80,000–100,000 nanometres wide.

This tiny size gives nanoparticles a huge surface area, which helps them mix well with polymers and block gases and moisture more effectively.

Furthermore, due to these high surface area to weight ratios, only a small quantity of nanoclay particles is required to achieve significant results. This means that typically, adding just 1–5 wt.% of nanoclay can improve barrier performance dramatically—without major changes to a polymer film's weight, recyclability, or other property.

For example, a recent study published in the journal Polymers found that nanoclay particles added to polypropylene (PP) in contents ranging from 0.8 to 6.4 wt.% improved the oxygen barrier qualities by as much as 64% when compared to PP alone. Even when the moisture content in the air was adjusted in ranges of between 0 and 90%, the amount of oxygen passing through the PP barrier remained consistent.

Nanoclay additives are able to slow down the diffusion of:

· Oxygen, which can spoil food and degrade pharmaceutical ingredients.

· Carbon dioxide, important in modified atmosphere packaging.

· Water vapour, which affects both food texture and active pharmaceutical ingredients.

The rates at which gas and moisture can pass through a polymer is dependent on the formulation and dispersion quality.

Additionally, using nanoclay to boost barrier properties lowers the environmental impact of packaging, as it allows for thinner packaging layers (reducing material usage), extends shelf life (reducing food and medicine waste), and is compatible with bioplastics (supporting compostable and recyclable packaging efforts).

Types of Nanoclays Used

The most commonly used nanoclay is montmorillonite, a smectite clay mineral with naturally layered silicate sheets, however other types used include kaolinite, hectorite, and halloysite nanotubes (HNTs). Although all of these nanomaterial feedstocks must be modified before they can be dispersed and properly interact within a polymer matrix.

Key Applications in Packaging

1. Food Packaging. Nanoclay-reinforced films are used to preserve snacks, meats, dairy, and ready meals by slowing down oxidation and microbial growth.

2. Pharmaceutical Blister Packs. In drugs sensitive to humidity and oxygen, nanoclay composites ensure longer shelf life without the need for foil laminates, reducing weight and cost.

3. Cosmetic and Personal Care Packaging. Improved barrier films prevent active ingredients like retinol or vitamin C from degrading prematurely.

Manufacturing Considerations

From a manufacturing perspective, incorporating nanoclays into polymers involves several key considerations. Firstly, uniform dispersion is critical—if the nanoclay particles are not evenly distributed throughout the polymer matrix, they may agglomerate, leading to poor barrier performance and mechanical inconsistencies. Achieving proper dispersion ensures that the nanoclays create an effective tortuous path for gas and moisture molecules.

Processing methods such as melt compounding and solution casting are commonly used to incorporate nanoclays into polymers. These techniques are well-established in industrial settings and allow for scalable production while maintaining the structural integrity and barrier enhancement of the final product.

Lastly, from a financial and operational standpoint, nanoclays offer a cost-effective solution. They are relatively inexpensive compared to other nanomaterials and can be integrated into existing manufacturing lines with minimal modification. This makes them particularly attractive for manufacturers looking to upgrade packaging performance without incurring significant capital investment.

Ultimately, nanoclay-enhanced polymers represent a practical, scalable solution for improving the barrier properties of packaging materials. With just a small additive load, manufacturers can extend product shelf life, reduce waste, and meet sustainability targets—all without sacrificing flexibility, clarity, or strength.

Nanotechnology inclusion in polymers is solving many problems faced by the manufacturers, including those in the packaging sector. For as consumer demand for longer-lasting, eco-friendly products grows, while regulations around packaging standards tighten, nanoclay-based barrier films are positioning themselves to become an industry standard.

Who knew that something as small as nanosized particles of clay could do so much?

Photo credit: Flickr, Freepik, Nk Ni on Unsplash, & brgfx& Gencraft