Stronger Polymers Composites from a Nanoparticle Boost

Revolutionising composite interfaces with accurate nanoparticle sizes.

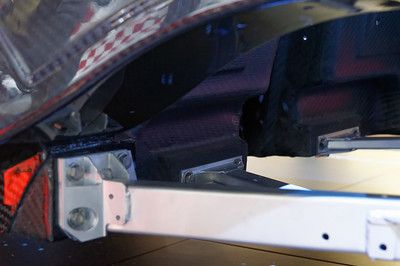

In the fast-evolving landscape of advanced manufacturing, the demand for stronger, lighter, and more thermally stable materials continues to grow. Industries such as aerospace, automotive, and defence are increasingly relying on carbon fibre-reinforced composites (CFRCs) due to their exceptional strength-to-weight ratio. However, one persistent challenge has been optimizing the interface between carbon fibres and the surrounding polymer matrix, where weaknesses can significantly limit performance.

A new study published in March 2025 in the journal Polymers presents a promising breakthrough which can dramatically improve interfacial properties in carbon fibre composites.

The Interface Problem in Carbon Fibre Composites

CFRCs are composed of strong carbon fibres embedded in a resin matrix, often an epoxy. But while both components are individually robust, the interface—the boundary where the two materials meet—has traditionally been a weak point. Poor adhesion at this junction can result in issues like delamination, reduced shear strength, and reduced durability, especially under mechanical stress or high temperatures.

To address this, manufacturers often use sizing agents—coatings applied to carbon fibres that promote better bonding with the polymer matrix. Traditional sizing agents, however, can degrade at elevated temperatures or fail to provide sufficient mechanical strength.

Enter Nano Zinc Oxide Core–Shell Sizing

To resolve this issue, nanomaterial researchers have developed a core–shell structure in which nanoparticles of zinc oxide (ZnO) form the ‘core’ and are encapsulated by a thin organic polymer ‘shell’. This dual-phase structure combines the best of two worlds: thermal stability and mechanical rigidity.

This is achieved as the organic shell improves compatibility with the epoxy resin, enabling stronger chemical interactions during the curing process. At the same time, the sizing agents were applied to the carbon fibres with uniform dispersion and strong adhesion to the fibre surface.

Yet equally significant, is the thermal stability of the new sizing agent with the composite maintaining its integrity at temperatures up to 300 °C, making it suitable for high-performance applications.

Applications and Industry Impact

The implications of this nanomaterial research could be widespread across the manufacturing sector or wherever polymer composites are used. For example, aerospace manufacturers can produce lighter, more durable parts without sacrificing performance at altitude or under high thermal loads. Automotive engineers can enhance crash resistance and structural rigidity while supporting electric vehicle weight reduction goals. While manufacturers in the defence sector could benefit from enhanced impact resistance in body armour and structural panels.

Moreover, the core–shell approach provides a scalable and adaptable platform. The ZnO nanoparticles could potentially be replaced with other metal oxides (such as TiO₂ or Al₂O₃) for tailored properties depending on the end-use environment.

Moving from Lab to Production

While the findings are compelling, real-world deployment requires further analysis. For this reason, nanotechnology companies, such as NANO POLYMER CENTRUM, have built custom research laboratories for developing nanomaterial additives for polymer products.

As the company (which hosts this webpage) has compiled a team with a blend of both academic and industry knowledge of polymer mechanics and manufacturing, it is ideally suited to work on how nanotechnology can be applied to real-world solutions.

This means that the team considers:

· Process compatibility with existing raw materials and composite lay-up lines.

· Cost-benefit analysis compared to conventional feedstocks and sizing agents.

· Long-term environmental durability, even under UV, moisture, and cyclic stress conditions.

This new ZnO-based sizing technology represents a significant leap forward in composite material engineering. For manufacturers seeking to push the boundaries of what's possible with carbon fibre-reinforced composites, nano-engineered interfaces might be the key to unlocking the next generation of lightweight, high-strength, and thermally resilient materials.

Furthermore, the study is another case of how the smart application of nanotechnology can be used to improve products or lower input costs in the manufacturing sector.

Stay tuned to blog.polymernanocentrum.cz for more updates on the latest in polymer nanotechnology and advanced manufacturing.

Photo credit: kjparageter on Freepik, DC Studio, & Flickr