Smart Windows and the Power of Nanotechnology in Coatings

Nanomaterial design creates a coating that can self-regulate heat.

Every building designer faces the same dilemma. Windows are essential for natural light and comfort, but they also let in infrared radiation — the part of sunlight responsible for heating interiors. In warm climates, this increases air-conditioning demand; in cooler regions, it can cause overheating in glazed buildings.

But what if glass could regulate the amount of heat that it lets into a building?

Researchers from Aarhus University’s Interdisciplinary Nanoscience Centre (iNANO) in Denmark have now unveiled a new approach with a prototype “smart window” which uses a nanostructured coating that automatically adjusts to sunlight without any external power source.

It is a discovery which highlights how nanomaterial additives in coatings can deliver energy-efficient functionality through intelligent design rather than added complexity.

Existing solutions, such as electrochromic windows or motorised shading systems, require power and electronic control. They work well but come with installation costs, long switching times, and maintenance demands.

This is where the Danish researchers and the intelligent use of nanotechnology combined to create a passive material that automatically regulates light and heat by reacting directly to changing sunlight conditions.

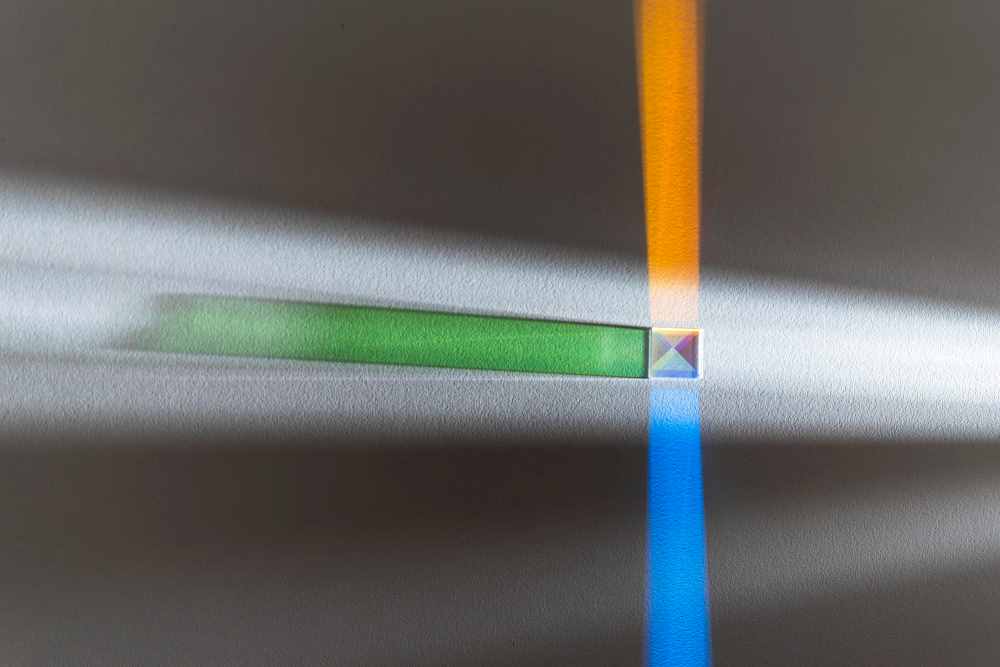

The discovery is based on the development of a thin coating embedded with silver nanorings which interacts with sunlight at specific wavelengths. As the intensity of sunlight increases, the nanomaterials scatter and reflect more infrared light (which carries heat), while still allowing visible light to pass through.

The magic lies in geometry and nanomaterial engineering. Each silver nanoring is precisely shaped and spaced to target the wavelengths of infrared radiation. Unlike flat films or pigments, these three-dimensional nanostructures manipulate light through resonance effects.

“We have developed a combination of materials whose optical properties change in response to sunlight,” explains researcher Xavier Baami González. “It allows heat to enter when the sun is low, but reduces heat radiation at midday—exactly when the need for cooling otherwise increases. And it all happens without any electricity.”

This effect is purely physical and requires no sensors, wiring, or power. The coating reacts instantly and continuously, adjusting its optical properties in real time. It essentially turns an ordinary window into a self-regulating heat shield.

By reducing infrared transmission, buildings could lower their cooling loads and energy use without sacrificing natural light — a critical step toward sustainable architecture and climate-neutral construction.

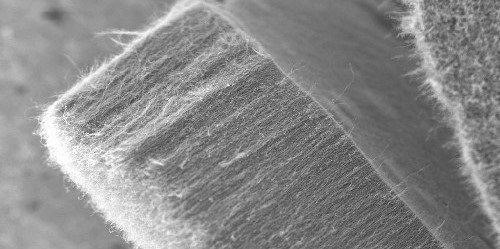

The coating can be applied as a nanocomposite layer on the surface or potentially embedded within the glass as a transparent polymer substrate. Here, polymer science plays a vital role as polymers can provide flexibility, adhesion, and mechanical stability — all properties essential for large-scale, durable coatings.

For practical deployment, the challenge will be in integrating the nanostructures into robust, transparent matrices that can withstand UV exposure, temperature changes, and cleaning processes over many years of use.

This means that for now, the research remains at the laboratory stage, because moving from small glass samples to full-sized window panels will require further investment in nanostructure fabrication techniques and coating uniformity. Additionally, cost-effective production methods, such as roll-to-roll coating or nanoimprint lithography, will also be essential for commercialisation.

Furthermore, long-term performance testing (for weathering, optical stability, and adhesion) will also be required before the technology reaches market-ready form. Yet, the principle is sound and promising: nanotech know-how built directly into materials rather than added through electronics.

Nanotechnology in Coatings: A Broader Revolution

This Danish innovation is one example of how nanotechnology is transforming the coatings sector. By structuring materials at the nanometre scale, scientists can control how surfaces interact with light, heat, water, and even microorganisms.

Other examples include:

· Self-cleaning nanocoatings that use photocatalytic nanoparticles to break down dirt and pollutants under sunlight.

· Hydrophobic polymer films that repel water, fog, or ice through nanostructured surfaces.

· Scratch- and UV-resistant nanocomposites for transparent plastics, extending product life.

· Photothermal coatings that harness sunlight to de-ice or heat surfaces efficiently.

In each case, the nanoscale design changes the material’s function without significantly altering its appearance — a perfect blend of performance and aesthetics.

Turning Nanoscience into Real-World Coatings

It is an approach which lies at the heart of the work being conducted at POLYMER NANO CENTRUM. Here a team of nanotechnology specialists has been created to develop polymer-based nanocomposites as well as functional coatings that enhance surface performance through advanced dispersion and nanoscale control. Nanotech solutions designed with manufacturing in mind.

Carbon nanomaterials can be as small as 10,000ththe width of a human hair and yet can have a huge influence on macroscale materials.

With its own purpose-built research centre, POLYMER NANO CENTRUM (which hosts this website) has industrial collaborations focused on:

· Nanoparticle integration within polymer matrices for improved barrier, optical, and mechanical properties.

· Functional surface coatings offering anti-corrosive, UV-resistance, or chemical protection.

· Custom formulation development for partners seeking sustainable, high-performance materials solutions.

Like the Aarhus researchers, the team at POLYMER NANO CENTRUM see nanotechnology not as a distant concept but as a practical design tool for today’s industries — one that enables materials to adapt, protect, and perform in ways that conventional chemistry cannot.

From power-free smart windows to multifunctional protective films, the message is consistent: the future of materials lies in the nanoscale. Intelligent coatings are no longer the realm of science fiction — they are emerging from the lab, ready to redefine how we build, protect, and interact with our environment.

To find out more about how POLYMER NANO CENTRUM can improve your resins, polymers, and coatings, contact +420 233 371 850 or visit POLYMER NANO CENTRUM.

Photo credit: Freepik, yanalya, Flickr, Freepik, & Macrovector