Reinventing Wood with Nanotechnology

For years nanomaterials have been making plastics better, but now even timber is being improved.

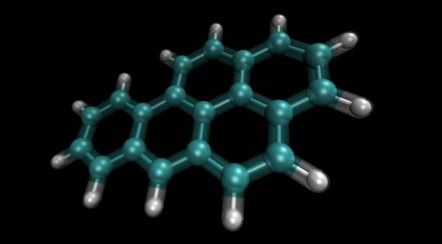

In recent years, researchers have discovered that by infusing materials with nanoparticles — such as nanocellulose, nano-silica, or even graphene — they can dramatically enhance their strength, durability, and functionality.

While nanotechnology has already improved manufacturing feedstocks, such as rubber, PVC, resins, cement, glass, ceramics, PE, PP, and polymer coatings, the latest research has found a way to use nanomaterials to give wood a boost.

The breakthrough was made by researchers from Florida Atlantic University, in collaboration with the University of Miami and Oak Ridge National Laboratory, who have developed a method to fortify wood by integrating nanocrystalline iron oxyhydroxide directly into the wood’s cell walls.

The heart of the discovery was based on the research team wanting to know if adding incredibly hard minerals at the nanoscale could strengthen wood without making it bulky, expensive, or environmentally harmful.

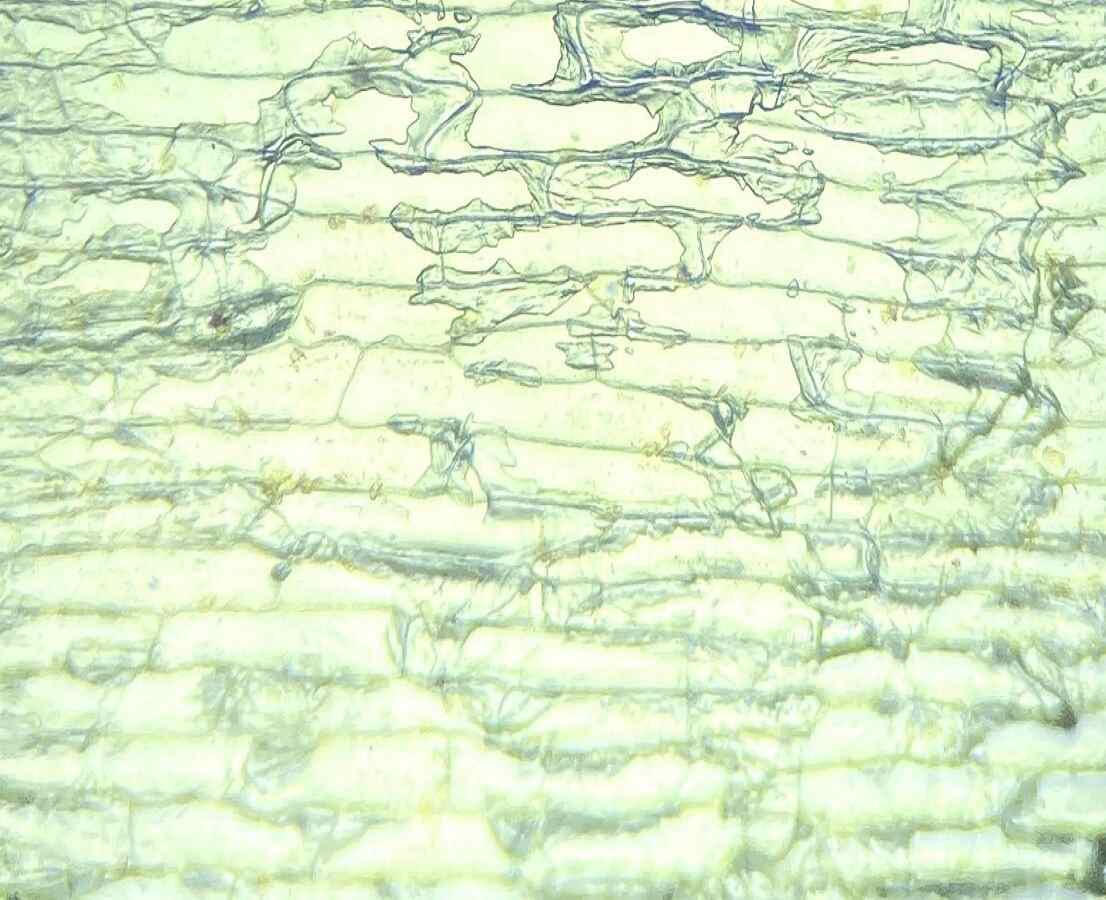

“Wood, like many natural materials, has a complex structure with different layers and features at varying scales. To truly understand how wood bears loads and eventually fails, it’s essential to examine it across these different levels,” explains Dr Vivian Merk, the study’s senior author. “To test our hypothesis – that adding tiny mineral crystals to the cell walls would strengthen them – we employed several types of mechanical testing at both the nanoscale and the macroscopic scale.”

Related articles: 7 Ways Nanomaterials Can Improve Polymer Products or How Nanotechnology is Giving Glitter a Green Makeover

While nanotechnology is an exact science, the principle behind the discovery is quite simple, involving a chemical reaction between ferric nitrate and potassium hydroxide, which results in the formation of ferrihydrite, an iron oxide mineral commonly found in soil and water.

The study has now been published in the journal of Applied Materials and Interfaces, where the author’s explain how , “Ferrihydrite nanoparticles were deposited inside the wood cell wall by an in situ chemical reaction, resulting in increased stiffness and hardness of the functionalized secondary cell wall, as evidenced by region-specific nanoindentation tests under an electron microscope.”

Further advanced imaging techniques, such as atomic force microscopy and nanoindentation tests, confirmed the uniform distribution of the iron mineral within the wood's cell walls. The wood was then tested using a technique called AM-FM (Amplitude Modulation – Frequency Modulation), which vibrates the AFM tip at two different frequencies. While one frequency gauges the material's stickiness and elasticity, the second frequency produces fine-grained surface pictures from which the researchers were able to see exactly how the nanomaterial treatment had changed the cell walls of the wood.

Significantly, the researchers found that the wood’s strength was improved despite adding only a small amount of extra weight.

However, the university press release notes that additional research is required to improve wood even further as, “Although the internal structure became more durable, the wood’s overall behaviour – such as how it bends or breaks – remained largely unchanged. This is likely because the treatment weakened the connections between individual wood cells, affecting how the material holds together on a larger scale.”

Approximately 182 billion tonnes of wood are generated year worldwide, making it one of the most abundant sources of renewable materials.Yet it has changed little as a raw material over the millions of years that humans have been using it. Only by adopting nanotechnology, can this sustainable, easily available resource be taken to the next level.

“By looking at wood at different levels – from the microscopic structures inside the cell walls all the way up to the full piece of wood – we were able to learn more about how to chemically improve natural materials for real-world use,” adds Dr Merk.

Moreover, if research into how nanomaterials can impact and improve conventional raw materials continues, then there is no reason why a feedstock such as wood could not replace non-sustainable raw materials in building industrial flooring, tower blocks, bridges, or even roads.

“This research marks a significant advancement in sustainable materials science and a meaningful stride toward eco-friendly construction and design,” notes Dr Stella Batalama, the dean at Florida Atlantic University’s College of Engineering and Computer Science. “By reinforcing natural wood through environmentally conscious and cost-effective methods, our researchers are laying the groundwork for a new generation of bio-based materials that have the potential to replace traditional materials like steel and concrete in structural applications. The impact of this work reaches far beyond the field of engineering – it contributes to global efforts to reduce carbon emissions, cut down on waste, and embrace sustainable, nature-inspired solutions for everything from buildings to large-scale infrastructure.”

But this nanotechnology is not a stand-alone project. As researchers continue to examine how to improve conventional raw materials with nanomaterial additives.

For example, by removing the lignin (the component that gives wood its colour) and replacing it with a nano-infused polymer, nanotech researchers have already created transparent wood, which is stronger, more insulating, and biodegradable than glass. Other nanomaterial-enhanced woods are being developed to better repel water, resist fire, or even store energy.

Applications of nanotechnology to traditional materials like these represent a promising shift in how we approach sustainable construction and material science. While still in its early stages, this pioneering research demonstrates the potential of nanoscale engineering to enhance the mechanical performance of one of the world’s oldest and most widely used building materials — all without compromising its natural qualities or ecological benefits.

From skyscrapers to smart furniture, the humble tree, empowered by cutting-edge nanotechnology, could become the cornerstone of a better, more sustainable way to manufacture and build.

Photo credit: Alex Jones on Unsplash, Christopher Stark, Giovanni Crisalfi, Wikimedia, & Greg Rosenke