Raw Materials with Stress Memory

Nanotechnology has just passed a new milestone in composite engineering design and damage control.

Anyone who has ever flown in a plane or driven over a bridge may wonder how engineers inspect the structure for stress and deterioration. Yet one of the most persistent challenges in modern materials engineering is not detecting damage, but understanding what a material has experienced before visible damage appears.

This is because many industrial components, including polymer films, plastic components, concrete pillars, and other composite structures, may undergo repeated mechanical loading long before cracks, delamination, or failure can be detected by conventional inspection methods. When stress is removed, the material often appears unchanged, offering no insight into its mechanical history and the damage it has received.

Now recent advances in nanotechnology have revealed a different approach to assessment by creating nanocomposite materials that do not merely respond to force in real time, but actually remember it.

The discovery is centred around a newly created phosphorescent nanomaterial based on carbon nanodots—a breakthrough which has been announced in the journal Advanced Science demonstrating how mechanical stress can be recorded, stored, and later erased in smart polymer systems and industrial monitoring.

The Current Restrictions of Conventional

Mechano-responsive luminescent materials have been studied for years as potential sensors. During impact, stretching, or compression, these materials change how they emit light, making mechanical events optically visible. However, most existing systems suffer from one of two fundamental limitations:

1. Inorganic phosphors tend to respond only while the force is applied, with the signal disappearing almost immediately once the load is removed.

2. Organic systems embedded in polymers can show longer-lasting changes, but these are often irreversible, meaning the material cannot be reused and may degrade after repeated loading.

However, the newly developed system addresses both problems by combining durability, reversibility, and memory in a single nanostructured material.

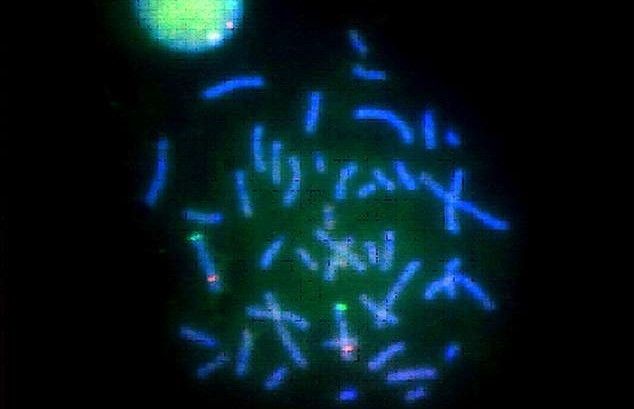

At the core of the innovation are carbon nanodots, a class of nanoscale carbon-based materials known for their low toxicity, chemical stability, and tuneable optical properties. On their own, carbon nanodots typically emit fluorescence rather than long-lasting phosphorescence. But a breakthrough was made by embedding them inside a crystalline framework formed by ring-shaped sugar molecules called cyclodextrins.

Because of their ability to host other molecules inside their cavities, cyclodextrins are widely used in industry, particularly in pharmaceuticals and formulations. However, in this latest nanotechnology system, the cyclodextrins create a rigid, hydrogen-bonded environment around the carbon nanodots. This supramolecular confinement suppresses molecular motion, allowing excited electrons in the nanodots to release energy slowly as visible phosphorescence, even after the physical trigger has passed.

How Mechanical Stress can be Stored in Nanomaterials

When mechanical stress is applied, the hydrogen-bond network within the cyclodextrin framework becomes distorted. This reduces the rigidity of the nanodots’ local environment, enabling molecular vibrations that dissipate energy as heat rather than light. As a result, phosphorescence intensity and lifetime decrease in proportion to the applied stress.

Crucially, this change does not disappear when the force is removed, as the stressed structure settles and remains locked in place under ambient conditions. In practical terms, the material retains a visible optical record of the mechanical load it has experienced, even minutes or hours later.

Moreover, the stored stress information can be erased by applying ultrasonic waves which provide localised vibrations to overcome the barrier holding the distorted hydrogen-bond network in place. Once this barrier is crossed, the crystalline structure re-forms, and the original phosphorescence properties are restored.

Related articles: Boosting Strength, Cutting Costs: Nanotech in Green Polymers and Nanotech Used in Novel Anti-Corrosion Polymer Coating

Repeated cycles of mechanical loading and ultrasonic recovery show consistent performance, confirming that the material does not suffer cumulative degradation. This reusability is a critical requirement for industrial deployment, where sensors and functional coatings must operate reliably over long service lifetimes.

Integration into Polymer Materials

To demonstrate industrial relevance, the nanodot–cyclodextrin system was incorporated into a polyvinyl alcohol film. The resulting composite retained its stress-memory phosphorescence while remaining flexible and mechanically robust. Even after hundreds of bending cycles, the optical response remained stable.

Why This Matters for Industry

The ability to embed reversible, memory-capable stress sensors directly into polymer materials represents a meaningful step forward for smart material design. Unlike conventional sensors that require wiring, power, or continuous monitoring, these materials store information passively and make it accessible through simple optical readout.

From an industrial perspective, the key advantages include:

· Reusable sensing without permanent material damage.

· Compatibility with polymer films, coatings, and composites.

· Optical readout that does not require continuous power or data streams.

· Reliance on non-covalent interactions rather than fragile chemical bonds.

Such characteristics are highly attractive for sectors where polymers and composites are exposed to repeated mechanical loads and where maintenance, quality control, or lifetime prediction benefit from knowing not just if damage has occurred, but how much stress a material has accumulated over time.

A Broader Advance in Nanotechnology Design

Beyond any single application, this work illustrates a broader trend in nanotechnology: moving from static property enhancement towards dynamic, information-bearing materials. By combining nanoscale emitters with supramolecular engineering, researchers are creating systems where mechanical, optical, and structural functions are tightly coupled yet fully reversible.

For industrial polymer research and development, this approach opens the door to new classes of multifunctional materials that sense, record, and recover without sacrificing durability. Yet another example of how nanotechnology is evolving from laboratory novelty into a practical tool for smarter, more efficient material systems.

Photo credit: Picryl, Picryl, Picryl, & Surfyan on Unsplash