Polymer Know-How for Stimuli Responsive Fabric

By examining polymer functions at a microscale, researchers have created a multi-responsive textile.

The future of wearable technology and soft robotic functioning took a large step forwards recently with the announcement of a smart fabric that responds to two different external stimuli in two separate ways.

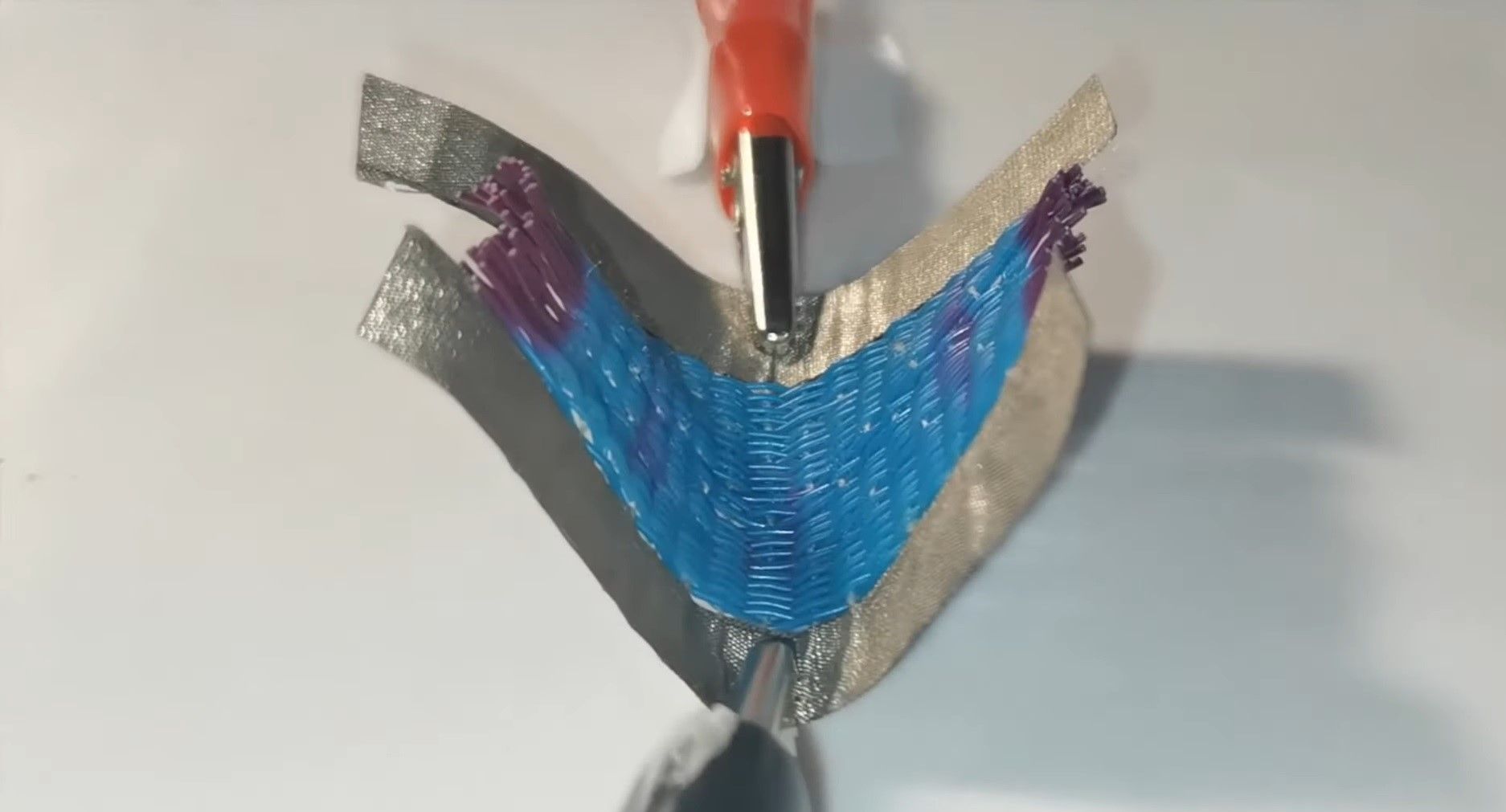

It is a world-first achievement that opens the door to a wide array of potential applications, as the textile bends when an electrical current is applied and changes colour when heated. For example, it could lead the way to clothing which warms the wearer up on a cold day or could lead to vehicle bumpers that return to their original shape after a collision.

Made with polymer nano-composite fibres from recycled plastic, this programmable fabric is the result of research conducted at the University of Waterloo in Canada.

“As a wearable material alone, it has almost infinite potential in AI, robotics and virtual reality games and experiences,” said Dr Milad Kamkar, a chemical engineering professor who took part in the study. “Imagine feeling warmth or a physical trigger eliciting a more in-depth adventure in the virtual world.”

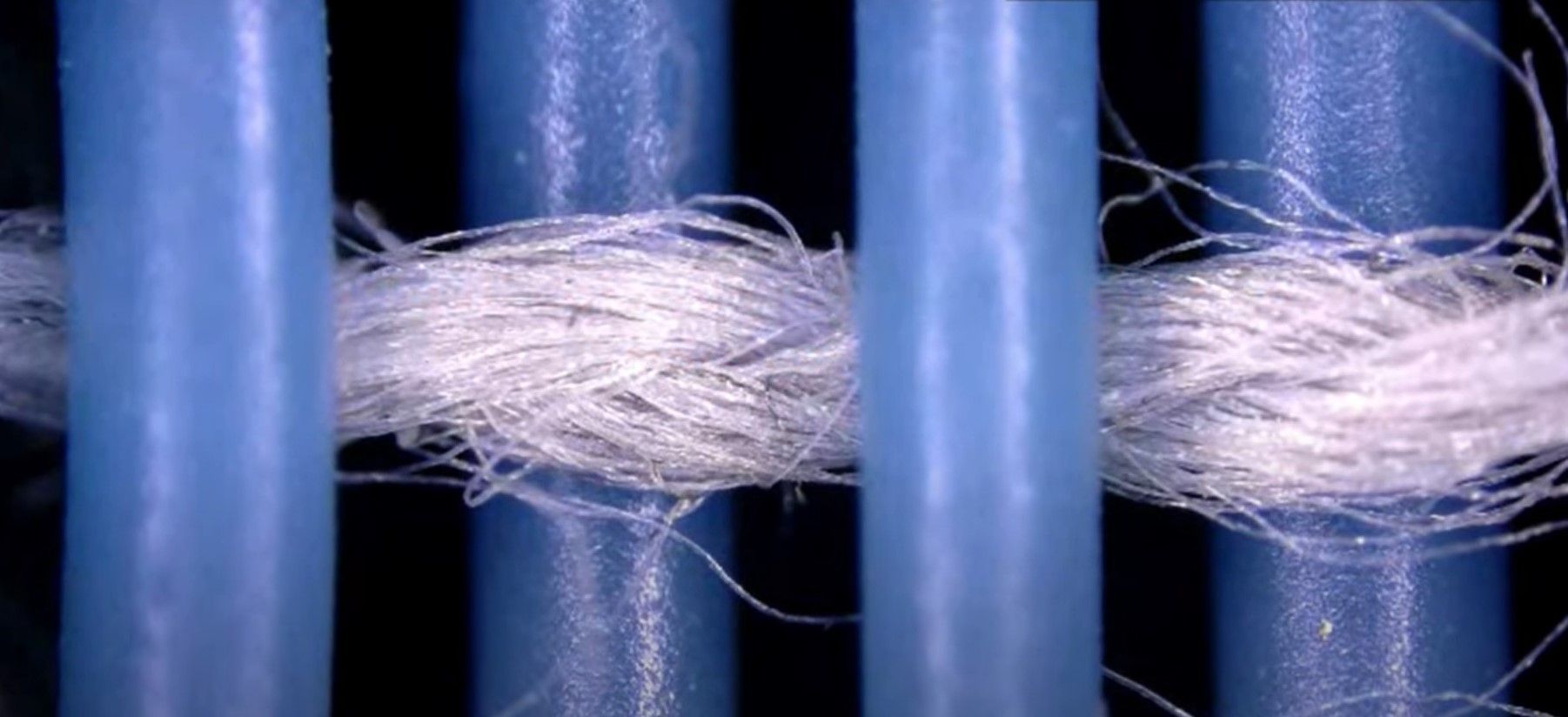

The fabric is made through a combination of highly engineered polymer composites and stainless steel in a woven structure, enabling design freedom and macro-scale control of the fabric’s properties.

To achieve this, the study explains, “… the weft yarns of the fabric consisted of polyethylene terephthalate (PET) and thermochromic microcapsules (TMC) through a twin-screw extruder. The warp yarns of the fabric were composed of blended yarns (PET/stainless-steel fibers [SSF]) of polyester fibers (PET) with SSF, imparting electrical properties to the system. The fabric was eventually woven on a loom according to a plain weave structure.”

The team have also published video evidence of the effectiveness of their novel nano-textile in a video where the fabric can clearly be seen to change colour under the heat of a household hair drier and bend and straighten under the application of a small electrical current.

In comparison to earlier systems, the fabric can also be activated by lower voltages of electricity, which increases its energy efficiency and lowers costs. It is also appropriate for use in biomedical devices and environment sensors since lower voltage enables integration into smaller, more portable devices.

“The idea of these intelligent materials was first bred and born from biomimicry science,” said Kamkar, director of the Multi-scale Materials Design (MMD) Centre at Waterloo. “Through the ability to sense and react to environmental stimuli such as temperature, this is proof of concept that our new material can interact with the environment to monitor ecosystems without damaging them.”

The research team is now working to improve the fabric’s shape-memory performance for better use in the field of robotics. The goal is to construct a robot that can effectively carry and transfer weight to complete tasks.

At present, the fabric's shape-memory and colour-changing capabilities can be controlled by altering the micro-scale design of the individual fibres in the structure.

It is a novel polymer design that is a product of the happy union of soft and hard materials. A versatile technology which combines low energy requirements, affordability, and accuracy, making it an ideal material for the development of the next generation of intelligent gadgets.

But more importantly, it is a sign of how polymer analysis at the micro and even nanoscale is influencing the world around us. A better understanding and application of raw materials, nanotechnology, and polymer ingredients is forming the future of coatings, plastics, packaging, robotics, medical implants, and now even stimuli-responsive textiles.

Photo credit: This is Engineering from Pexels, XR EPO on Unsplash, Albin Berlin on Pexels, & Waterloo University