New EU Guidance on Nanomaterial Safety Explained

What do the new EU regulations on nanotechnology mean for industrial manufacturing?

Nanomaterials are already part of everyday life — in polymer composites that are stronger and lighter, in coatings that resist scratches, in packaging that keeps products airtight, and electronics that are smaller and more efficient. These materials are carefully engineered and tested, with safety as a top priority.

But as nanotechnology evolves, the regulations governing how nanomaterials are manufactured, assessed, applied, and tested must also be updated.

Consequently, the European Commission’s Joint Research Centre (JRC) has published new guidance aimed at improving the safety testing of manufactured nanomaterials — a development with direct relevance for industrial producers of everything from epoxy flooring to polycarbonate sheets.

What is the New Guidance About?

The new nanotechnology guidance issued by the JRC is designed to work within existing EU chemical legislation, including REACH, by providing clearer and more practical recommendations on how and where nanomaterials are used.

Unlike conventional chemicals and industrial ingredients, nanomaterials behave very differently depending on their size, shape, surface chemistry, and how they are processed or embedded in other materials. The latest advice acknowledges this complexity and aims to harmonise safety testing approaches across Europe, helping both regulators and industry work with a shared framework.

What has Changed Compared to Previous Approaches?

One of the most important shifts in the new guidance is its stronger focus on real-world industrial conditions. Earlier safety assessments often relied on simplified laboratory tests that did not fully reflect how nanomaterials are used in manufacturing or how they behave during processing.

Additionally, much like the direction given on industrial chemicals, applications of nanotechnology in industry should now have greater emphasis on lifecycle thinking — from production and formulation through use and end-of-life stages. The guidelines also recognise that nanomaterials may change during processing, for example through agglomeration, surface modification, or interaction with polymer matrices. This is particularly relevant for polymer-based applications, where nanoparticles are rarely used in isolation but are typically embedded within composites instead.

What Does this mean for Manufacturers?

For companies working with nanomaterials, the new guidance signals a move towards more structured and transparent safety practices. This means that manufacturers may need to consider safety aspects earlier in the product development process, rather than treating them as a final regulatory hurdle before market entry.

Doing so will require closer collaboration between R&D, quality control, and regulatory teams. While this may initially increase testing and documentation efforts, it can also reduce long-term risks by preventing costly redesigns, regulatory delays, or market withdrawals later on.

Safety as an Opportunity, Not Just an Obligation

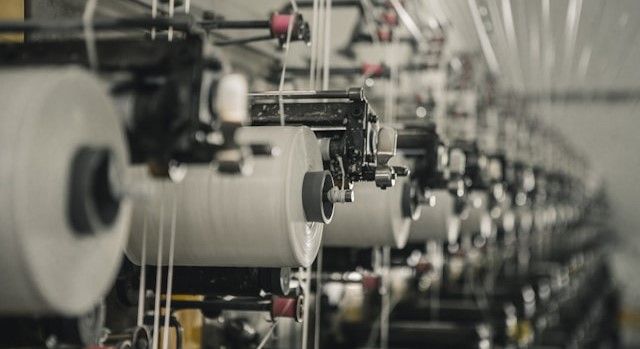

Although regulation is often seen as a constraint, improved safety guidance can also drive innovation. For example, as more raw materials are improved through the smart application of nanotechnology or the nanoscale modification of bulk feedstocks, it becomes cost effective to ensure that they act predictably and consistently. While the safety aspect of this may seem like an added burden, it can in fact lower costs by reducing waste. It can also generate value through higher-quality products as in competitive markets, reliability, consistency, and safety are key advantages.

Clear safety frameworks also help build trust — not only with regulators, but also with customers and end users. As awareness and use of nanotechnology grows, transparency around safety will play an increasingly important role in market acceptance.

Manufacturers looking to ensure compliance with the new nanomaterial safety guidance do not have to navigate the rules alone. Nanotechnology consultants and advisors are available to help companies interpret and apply the regulations effectively. Alongside other leading specialists in nanomaterials, the Czech company POLYMER NANO CENTRUM unites industrial expertise in polymers, resins, coatings, and construction materials with academic understanding of materials at the nanoscale. This combination allows the company to not only provide safety testing and regulatory support, but also to offer practical guidance on material characterisation, process optimisation, and implementation strategies for manufacturing.

POLYMER NANO CENTRUM (who support this webpage) can assist businesses in integrating nanotechnology into products responsibly, identifying potential challenges early, and improving performance, durability, and sustainability. With access to its own testing and research laboratories, the centre enables manufacturers to incorporate safety considerations from the very beginning of product development. This approach helps advanced polymer-based materials move smoothly from concept to commercial production while maintaining high standards of quality and regulatory compliance.

Ultimately, the future of nanomaterials in industry will rely not just on what these materials can achieve, but on ensuring they are developed and used responsibly, safely, and efficiently. By combining scientific expertise, practical know-how, and regulatory insight, institutions like POLYMER NANO CENTRUM play a vital role in making that future possible.

Photo credit: Gencraft, Pallab Kumar Nakti on Unsplash, Kevin Limbri, & Manh LE