Nanotechnology: The New Force in EM Wave Shielding

Nanotechnology is offering a new era of much-needed electromagnetic wave-absorbing materials.

In today’s hyper-connected world, electromagnetic (EM) waves are everywhere—from radar systems and wireless networks to smart buildings and industrial electronics. While these waves are essential, they also pose challenges: interference, data leakage, and even health concerns in high-exposure environments. For this reason, demand for modern raw materials that can effectively absorb EM radiation—without adding weight, thickness, or environmental risk—is rapidly growing.

Fortunately, nanotechnology is providing answers to this 21st century problem.

For example, a recent study has created an innovative, magnetic–carbon hybrid material that sets new records in microwave absorption, corrosion resistance, and flexibility. The discovery was made by a team of nanomaterial specialists from China’s Shandong University of Technology which found this new form of EM-absorbing materials by utilising nanostructured films.

What are Nanostructured EM-Absorbers?

At their core, EM wave-absorbing materials convert incident electromagnetic energy into heat, thus reducing signal reflection and interference. Traditional absorbers like ferrites and carbon black are bulky, heavy, and often limited in bandwidth.

Nanostructured materials change the game by manipulating matter at the atomic or molecular level. This enables manufacturers to engineer surfaces and interfaces that:

· Enhance dielectric loss (from polarisation and conductivity).

· Maximise magnetic loss (via spin alignment and resonance).

· Improve impedance matching (for optimal energy transfer into the material).

· Encourage multiple scattering within porous or layered structures.

These mechanisms make nanomaterials especially attractive for designing broadband absorbers. In the case of the Shandong University discovery, it even shows that these high-performance EM-absorbing materials can be lightweight, durable, and scalable.

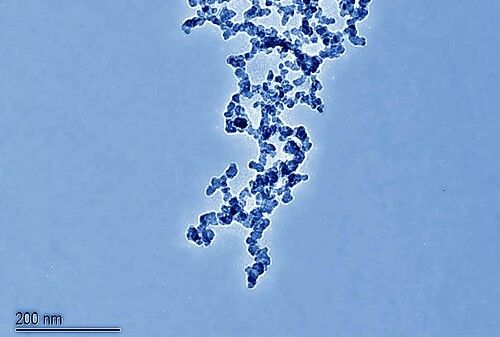

In the study, which has now been published in the journal Nano Research, the nanotech specialists created a composite material by anchoring hard magnetic Fe₃C and soft magnetic ZnFe₂O₄ nanoparticles onto two-dimensional reduced graphene oxide (rGO) nanosheets. This composite, referred to as rGO/FZC-1, combines the dielectric properties of carbon with the magnetic interactions of the nanoparticles—resulting in unmatched synergy.

Specifically, the research noted key performance highlights, including

· Extremely low reflection loss (as low as –65.6 dB), indicating excellent EM wave attenuation.

· Broad effective absorption bandwidth (4.56 GHz at 2.2 mm thickness).

· Stable performance in harsh environments thanks to the corrosion-resistant carbon scaffold.

· Flexible film form factor, ideal for practical applications in electronics or surface coatings.

The performance of the material is rooted in its nanostructure, where the contact between hard and soft magnetic phases creates exchange interactions that enhance magnetic loss. This is a known strategy in spintronics, now applied to EM absorption. This it achieves all while using polarisation loss and electron conduction to absorb part of the wave energy and converting it to heat, much as in conventional EM-absorbing materials.

At the same time, a layered, porous nano-architecture encourages internal reflections, which prolong the path of EM waves and increase the chance of energy dissipation.

Together, these features create an absorber that is thin yet powerful, lightweight yet robust—precisely what industry needs.

More importantly for the manufacturing sector, this latest nanomaterial composite isn't just a marvel for the laboratory. As it was synthesised via a scalable in situ gel process, it can be applied to large areas or integrated into flexible films and coatings. That makes it a strong candidate for real-world adoption.

Moreover, like other nano-enhanced composites, these raw materials contain other desired properties, such as corrosion resistance and compatibility with flexible substrates (enabling integration into electronics, garments, or structural composites), and contain no heavy metals or toxic binders (aligning with sustainability and safety targets).

Professor Dong Wang, who led the research, notes that this breakthrough (and others like it) in nanotechnology composite design “opens new avenues for interface engineering, with applications spanning electromagnetic shielding, corrosion-resistant coatings, and stealth technology.”

These can be applied to:

· Defence: These thin, high-performing films can reduce radar signatures on drones, aircraft, vehicles, or naval equipment.

· 5G Interference Control: In smart buildings or critical infrastructure, EM shielding films can reduce cross-talk and data leakage.

· Wearable Electronics: Flexible, breathable shielding layers for clothing and smart textiles.

· Electronics Packaging: Integrated EMI shielding for compact electronic devices, protecting components from external interference.

· Corrosion-Resistant Coatings: Ideal for use in coastal, industrial, or transportation environments where exposure is a concern.

As electromagnetic interference becomes increasingly prevalent—from telecommunications to transportation—the ability to integrate lightweight, scalable, and high-performance shielding materials directly into components, surfaces, and structures is becoming essential. The development of this nano-enhanced composite is a further clear signal that nanotechnology is no longer just an enabler of innovation—it is becoming an industrial standard.

For manufacturers seeking to future-proof their products against EM challenges while meeting sustainability and durability demands, the next generation of nanostructured composites offers both a technical edge and a commercial opportunity.

The Czech company POLYMER NANO CENTRUM tracks such developments closely to help manufacturers apply the latest nanoscience to their products. From chemical resistance, anti-static properties, electrical conductivity, chemical durability, or electromagnetic shielding, now is the time to investigate what nanotechnology can deliver.

Photo credit: Rostyslav Savchyn on Unsplash, Freepik, Freerangestock, Wikimedia, & Wikimedia