Nanotechnology That Sticks

How nanoscale engineering is reinventing adhesion.

In the world of advanced materials, it’s often the smallest features that make the biggest difference. As scientists continue to design smarter, more adaptable systems, nanotechnology is playing a vital role—quietly reshaping the way materials interact, respond, and perform.

One fascinating example comes from the field of dry adhesives—residue-free materials that rely on van der Waals forces to grip surfaces without glue or magnets. Long seen as promising for robotics, electronics, and clean manufacturing, dry adhesives have remained limited in one crucial respect: they only grip well when surfaces meet in perfect alignment. A few degrees of tilt, and the adhesion weakens dramatically.

But now, researchers at Xi’an Jiaotong University in China have tackled this problem using a combination of biomimicry and nanoscale design. Inspired by the structure of gecko feet, they’ve developed a clever internal mechanism and carefully engineered nanostructures to form a new dry adhesive that self-adjusts to angled surfaces.

Conventionally, dry adhesives have been made by mimicking nature’s use of weak intermolecular forces—van der Waals interactions—to create a temporary bond without residue. This works brilliantly in controlled lab settings, but in real-world environments, surfaces are rarely perfectly aligned.

When contact angles are off, stress concentrates in specific areas, causing early peeling or slippage. This has made dry adhesives unreliable for critical applications like robotic gripping or optical component handling, where precision and versatility are essential.

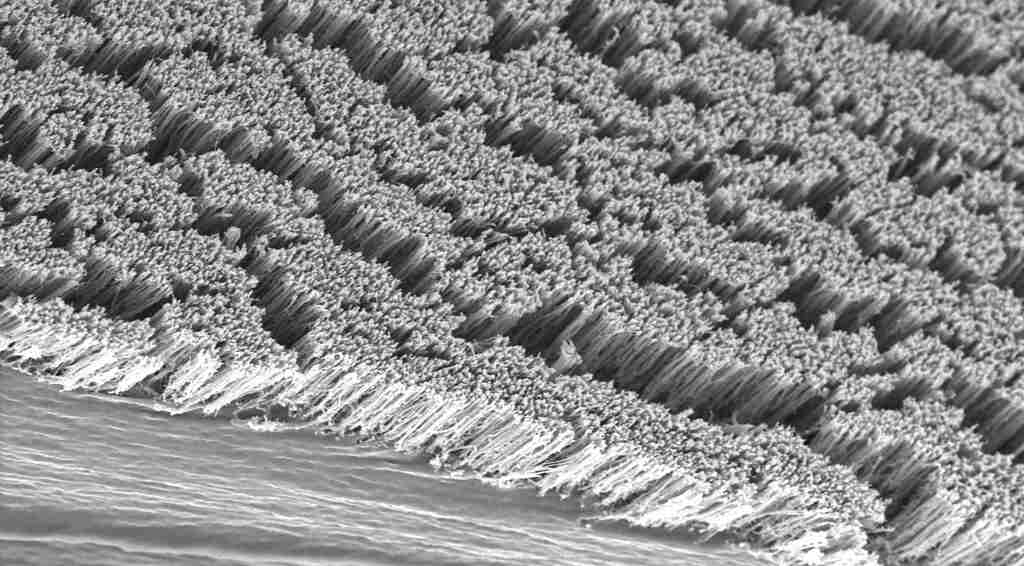

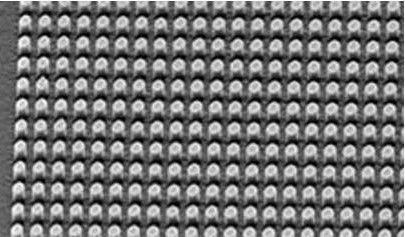

What made the breakthrough possible for this discovery was an improved understanding of the core–shell adhesive structure found in a gecko’s adaptable foot anatomy. At the surface, they use mushroom-shaped micropillars—each just microns in diameter—with surface roughness at the nanometre scale. This nano-texturing enables the adhesive to make extremely close contact with surfaces, maximising molecular grip.

Beneath that, the real innovation begins as the adhesive contains a rigid internal core embedded in a soft silicone shell, acting like a movable joint. When pressed against a sloped or angled surface, the core rotates slightly, bringing the contact surface into better alignment and distributing stress more evenly.

The result is a dry adhesive that adapts in real time, maintaining its hold even on slanted, misaligned, or curved surfaces.

Computer simulations confirmed that the internal pivot mechanism, paired with nanoscale surface design, enormously improved adhesion performance under angular misalignment compared to traditional, single-material dry adhesives.

As the study, now published in the journal Engineering, notes, “Compared with conventional soft/rigid adhesives, the adhesion strength of core–shell adhesives under misalignment (2°) increases by approximately 100 times. Moreover, inserting a rigid piece into a soft elastomer can generate good adhesion strength in alignment and misalignment situations.”

Better still, the adhesive maintains performance across varying temperatures and humid conditions—a notoriously difficult challenge for dry adhesion technologies.

To demonstrate its potential, the researchers mounted their adhesive onto a robotic arm, then used it to grip and move an angled optical lens—a task that would typically challenge conventional adhesives. The system worked seamlessly, proving the adhesive’s potential for precision manufacturing, optical assembly, and robotic handling.

These applications demand not just strong grip, but reliability, repeatability, and cleanliness—traits made possible here by combining smart mechanical design with nanostructured surfaces.

However, this adhesive is more than just a clever invention. It’s part of a larger trend: using nanotechnology to turn passive materials into adaptive, functional systems.

Where traditional adhesives rely on brute strength or chemical bonds, this approach takes a subtler, smarter route—engineering at the nanoscale to create materials that respond to their environment in real time. The result is a dry adhesive that doesn’t just stick—it thinks.

And this is just one example. Across industries, nanotech is enabling new possibilities in smart textiles, biomedical devices, energy storage, and more. The lesson is clear: when we design from the bottom up—starting with molecules and structures measured in nanometres—we unlock performance and functionality that conventional methods simply can’t reach.

As this gecko-inspired adhesive shows, nanotechnology is more than miniaturisation—it’s a powerful tool for rethinking materials from the ground up. Whether in robots, electronics, or beyond, the future of adhesion—and perhaps many other material challenges—will be built at the nanoscale.