Nanotechnology is Going Mainstream for Industry

How polymer nanocomposites are taking manufacturing by storm.

Nanotechnology is transitioning from a laboratory curiosity to an industrial reality. The clearest evidence of this shift in manufacturing and raw material sourcing can be found in the automobile sector—so frequently a leading light in innovation.

Through the application of nanotechnology, automobile manufacturers are finding ways to replace conventional metal, plastic, or rubber parts with polymer nanocomposites which provide numerous advantages in terms of cost, environmental protection, and unique-selling points.

This is achieved by going beyond conventional material performance to offer:

· Cost efficiency: Enhanced mechanical strength, thermal stability, and wear resistance reduce material usage, extend product lifespan, and lower maintenance or replacement costs.

For example, by including nanomaterials in a polymer composite to provide added strength allows for less conventional fillers to be used—often reducing overall feedstock costs.

A further advantage can be seen in quicker processing cycles. For example, a nanomaterial-enhanced thermoplastic may take only three processes to transform from granules to the final product, whereas die-casting and sheet metal fabrication usually take six steps.

· Environmental protection: Improved durability and functionality lead to less waste, lower energy consumption during production, lower final product weight, and reduced reliance on harmful additives or coatings.

For example, replacing a tractor’s metal hinge with a polymer nanocomposite reduces the part’s weight which improves fuel performance while maintaining superb mechanical strength and durability thanks to the nanomaterial’s inherent properties.

· Unique-selling points (USPs): Incorporating nanomaterials enables products with superior properties — such as antistatic behaviour, barrier performance, or flame retardancy — providing a clear differentiation in competitive markets.

For example, a rubber fuel tube in a car can induce a build-up of static electricity and a serious risk of engine fire. By including nanomaterials into the rubber, or by replacing the rubber completely with a plastic nanocomposite, the tube can be given antistatic properties, producing a safer vehicle.

These combined benefits allow manufacturers using nanotechnology to deliver high-performance, sustainable products while strengthening profitability and market positioning. A situation which has positioned the nanocomposite market at the forefront of modern industry with a projected value of more than $7 billion by 2033, expanding at a CAGR of 9.4%.

From Pilot to Production – Preparing for Nano-Scale Additives

While the development of nanocomposites by the automobile industry may sound like a project requiring the R&D budget the size of Tesla’s, today’s nanotechnology is far more affordable for even modest SMEs.

This is because rather than requiring bespoke laboratory formulations or multi-year R&D programmes, manufacturers can now access off-the-shelf nanomaterial concentrates designed for direct integration into polymer systems. These ready-to-use products reduce the complexity, cost, and lead time traditionally associated with nanocomposite development, allowing even small manufacturing enterprises to benefit from high-performance materials without major capital investment.

This route for adopting nanotechnology in manufacturing is possible thanks to companies like NANO CHEMI GROUP, who sponsor this page and offer a range of nanomaterial composites for inclusion in coatings, plastics, epoxy resins, and more. To learn more about this approach, contact info@nanochemigroup.cz or see the product list at NANO CHEMI GROUP.

Why Nanotechnology Matters for Polymer Manufacturers

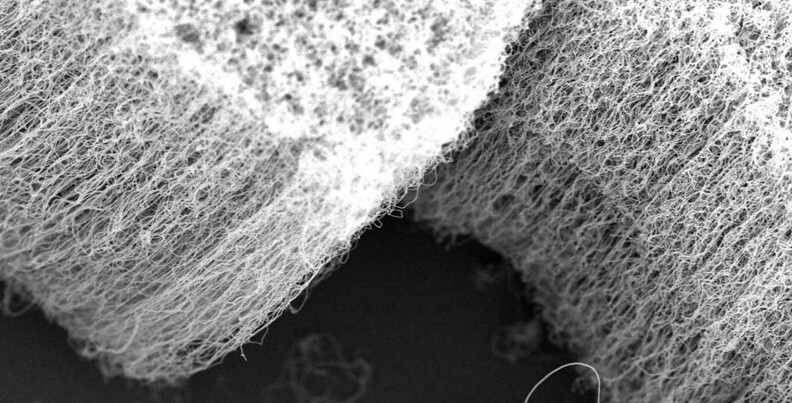

Traditional fillers like carbon black and silica have served the polymer industry for decades. However, nanotechnology introduces advanced fillers such as carbon nanotubes (CNTs), graphene, and nanoclays, which can significantly enhance polymer properties.

These nanocomposites offer improved mechanical strength, thermal stability, electrical conductivity, and barrier properties. For manufacturers, adopting nanocomposites can lead to lighter, more durable products with multifunctional capabilities, meeting the stringent demands of modern applications.

An alternative to off-the-shelf nano-based additives is to adopt a tailor-made nanocomposite formulation. Research teams like the nanotechnology experts at POLYMER NANO CENTRUM provide solutions to manufacturing issues by selecting the right nanomaterials for specific performance targets.

By bridging applied research and industrial supply, POLYMER NANO CENTRUM (who also sponsor this website) helps manufacturers implement nanotechnology reliably and efficiently, transforming what was once a high-tech experiment into a practical, cost-effective tool for innovation. All while ensuring compatibility with existing processing equipment.

Polymer nanocomposites have moved far beyond the realm of experimental science to become a practical and transformative force across industries — especially in automotive manufacturing. By combining the strength, lightness, and versatility of polymers with the remarkable performance of nanoscale additives, these materials are redefining what’s possible in design, durability, and sustainability.

For manufacturers, the opportunity lies not only in improving product performance but in saving production costs by being more efficient, environmentally responsible, and cost-effective. With ready-to-use nanomaterial concentrates and expert formulation partners now widely available, nanotechnology is no longer a distant innovation — it’s a competitive necessity.

Photo credit: Andy Luo on Unsplash, Freepik, usertrmk, & Flickr