Nanotechnology and Tomorrow’s Infantryman

How will nanotechnology better protect and serve a regular soldier?

The military has always been at the forefront of technology. From the ancient Macedonian Phalanx to the English longbow, to the atomic bomb. Technological advances have always been an effective way to give one army a winning edge over the other.

With the application of nanomaterials now widespread in all industries, their application in technological advances for the military is guaranteed.

But while nanomaterials are now deployed in a wide variety of military equipment, such as aircraft coatings, artillery shell cases, naval communication systems, tank armour, and other pieces of military hardware, they also have many current and future uses for foot soldiers.

Here is an examination of where and how nanotechnology will aid ‘boots on the ground.’

Nanotech for Strength with Low Weight

The average weight of batteries carried by US Army combat personnel in Afghanistan was as much as 4.5kg – with more technical soldiers required to carry as much as 13kg. When this weight is added to the 30 to 50 kilos of equipment and uniform worn in the field, then it is clear that weight is a real issue for infantry battalions.

At the same time, equipment and clothing worn in combat situations must be durable, crack resistant, sometimes waterproof, and must be able to operate in extreme weather conditions.

Nanomaterials are an ideal solution to this issue as they are exceptionally strong, yet also lightweight. They are widely used to strengthen rubber, plastics, and textiles, as well as providing crack and impact resistance.

They are already used in the manufacture of higher-end sports shoes and clothing and will feature in the boots and battledress of soldiers everywhere over the coming years.

Nanotech in Power Generation

For example, nano-enabled photovoltaic, thermoelectric, and piezoelectric devices are on the cusp of being able to harvest electricity from solar energy, waste body heat, and kinetic motion from a soldier’s movement. In many cases, these power sources could be embedded directly inside the uniform fabric, with enough power for a radio or to heat the suit or operate cooling as protection against hyperthermia/heat stroke.

Recently, a group of Japanese nanomaterial researchers recently demonstrated ultra-thin flexible organic photovoltaic devices with an efficiency of almost 8% by using a new material called PNTz4T. These electrical power sources were integrated into the textile which remained washable.

Alternatively, a thermoelectric device can convert heat energy into electrical energy. It is a technology which employs the Seebeck effect, a phenomenon where a temperature difference between two dissimilar electrical conductors produces a voltage difference between the two substances.

While their efficiency has always been low, advances in nanotechnology have created wearable thermoelectric devices. While at present the low electrical voltage produced (as little as several µW) means that only quite simple equipment can be powered, nanomaterials such as bismuth telluride, carbon nanotubes, and graphene have improved the power outputs considerably. At the same time nanotechnology is lowering electrical demand by creating ever-smaller electronics. This combination makes nanomaterials the gateway towards wearable, heat-powered equipment built into a soldier’s battledress.

Nanotech in Batteries

The go-to option for powering portable electronics for both military and non-military use, are lithium-ion batteries due to their high energy density, long lifespan, and because they are rechargeable.

Battery designers are looking at how to use graphene, which shows great promise as a cathode raw material. It can maintain electron transfer efficiency, is flexible, thin, and has a comparable performance to conventional feedstocks, such as aluminium and copper.

Moreover, embedding graphene with tin oxide nanoparticles as an anode and current collector can provide significant anode capacity alongside electrochemical stability.

Nanotech Sensors in Textiles

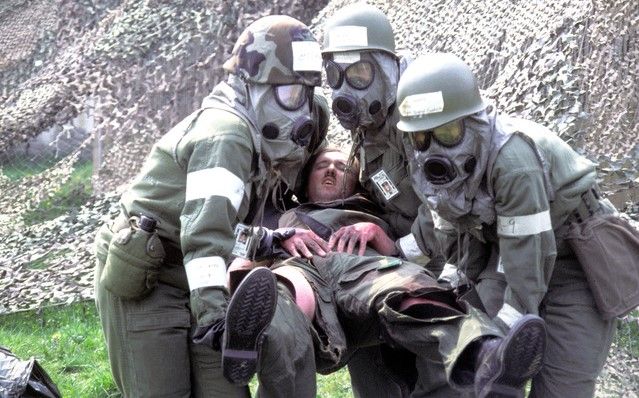

Researchers are making intensive efforts to develop nanotechnology-driven textiles embedded with nanosensor elements for Chemical, Biological, Radiological, and Nuclear (CBRN) threats. As the industry journal Nanowerk explains, “… because of their atoms / molecules available on the surface as compared to those in the core (high surface to volume ratio), [nanomaterials] are of particular interest for detection, protection and decontamination of CBRN warfare agents.”

Due to the nature of battle these fabrics must also be waterproof and insulating as well as provide light weight bullet and splinter protection.

It is hoped that full integration of all these technologies will result in a dynamic, lightweight, and comfortable-to-wear battle suit.

Nanotech in Body Armour

There is currently a strong focus on researching and developing nanomaterial-enabled body armour that is lighter in weight than current bullet and blast proofing which weighs around 14-15 kg.

To meet the criteria for ideal body armour, the raw materials used must not only prevent bullet penetration but also be able to deflect or bounce off bullets with elastic energy.

Nanomaterials such as magnetic and non-magnetic ceramics, as well as carbon-based materials like carbon nanotubes (CNTs) and graphene, are being explored as possible ultra-lightweight options.

Carbon nanomaterials, in particular, have several attributes that make them highly suitable for creating ultra-light body armour, such as their low weight, ability to form strong composites in polymer and ceramic matrices, and high resistance to thermal degradation and absorption of high-energy impacts.

For example, simulations have shown that a CNT of sufficient length can stop a bullet without piercing through, thanks to its ability to absorb kinetic energy. Graphene, which has a honeycomb 2D structure, has similarly impressive mechanical properties, including a high resistance to deformation (measured by Young's modulus).

The specific penetration energy resistance of multilayer graphene is also ten times higher than that of macroscopic steel sheets at a bullet speed of 600 ms^-1, making it a much stronger option for body armour.

Composites of graphene and CNTs in a polymer matrix, such as polythene, have been shown to provide a stronger bulletproof armour that is significantly lighter in weight (by up to 70%) than current body armour options. However, the practicality of fabricating stand-alone armour for individual soldiers remains a challenge.

Nanotechnology represents a significant opportunity for the military to enhance the way soldiers are equipped to fight. The potential applications of this technology are vast, from creating lightweight and durable armour to developing medical solutions to rapidly heal injuries on the battlefield. While much is still unknown about how these technologies will be implemented, the prospect of a smarter, more effective infantryman provides a lens into the future of warfare.

Photo credit: HIZIR KAYA on Unsplash, Picryl, Dariusz Sankowski from Pixabay, Wikimedia, Nara, Picryl, Wikimedia, centaur60, Gordon Taylor from Pixabay, Creative Commons