Nanotech for Industry

How nanomaterials are transforming industrial coatings, resins, and polymers.

Nanotechnology is no longer confined to laboratories or research journals. It has entered production floors, manufacturing plants, product lines, and the supply chains of advanced material manufacturing.

Defined simply, nanotechnology involves manipulating matter at the scale of billionths of a metre—about the size of twenty hydrogen atoms placed in a row. At this scale, materials acquire unique physical, chemical, and mechanical properties that conventional materials cannot match.

Related articles: Boosting Strength, Cutting Costs: Nanotech in Green Polymers or Plastic Regranulate Gains New Life from Nanomaterials

Recent developments in industry are highlighting how nanomaterials are reshaping multiple sectors—from energy and healthcare to manufacturing and construction. Yet for the coatings, resins, and polymers industry, the implications are particularly significant, as nanotechnology is enabling the creation of stronger, lighter, and more durable materials, offering manufacturers an opportunity to differentiate themselves in a highly competitive market.

What Nanotechnology Means for Coatings, Resins, and Polymers

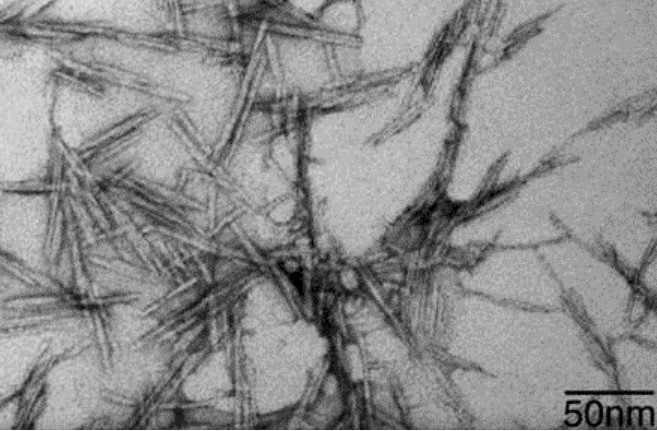

The ability to engineer materials at the nanoscale allows scientists and manufacturers to tailor performance characteristics in entirely new ways. In coatings and polymers, this often means integrating nanoparticles, nanofibres, or nanolayers into traditional formulations to enhance functionality without altering the overall composition or appearance of the product.

“Nanostructure technology allows 100% modification of secondary raw materials, both in order to maintain the conventional properties of materials at the required level (for example, impact strength) and in order to obtain new material properties (for example, obtaining thermally or electrically conductive plastics),” explains Lev Lyapeikov, a nanomaterial expert at POLYMER NANO CENTRUM. “It is a process which can modify either the entire volume of a material or only its surface for a more efficient use of nanoparticles.”

The advantage of using nanoscale-sized particles (nanofillers) in polymers is because they have such an extremely high specific surface area, typically ranging from 800 to 1,600 m² per gram of filler.

With such a high surface area, the chemical impact of the nanomaterials is highly efficient, meaning that only an incredibly low loading rate (starting at 0.025% or less) is required. As a result, bulk materials can maintain all of their original properties, while still gaining the desired mechanical, conductive, electromagnetic qualities, improved scratch resistance, UV and heat stability, and chemical durability, while also introducing new properties such as self-cleaning, anti-corrosive, or antimicrobial effects.

For instance, nanotubes included during a polymer coating’s production can create ultra-thin barriers within the mixture which resist oxidation and degradation far better than standard paints or films. These advances are particularly valuable in industrial sectors where durability, energy efficiency, or surface performance translate directly into cost savings.

Key Industrial Applications for Nanotechnology and Case Examples

Nanotechnology has already transformed several industrial fields. In the electronics sector, for instance, polymer nanocomposites incorporating conductive or semiconductive nanoparticles are being used to produce flexible circuits, sensors, and wearable devices.

Environmental technologies are another area of growth, as nanostructured membranes and coatings are being deployed for filtration, water purification, and anti-fouling systems. Polymers containing nanoscale titanium dioxide or graphene oxide, for example, exhibit improved adsorption of pollutants and greater mechanical stability under pressure.

Nanomodification is enabling even conventional polymers such as polycarbonate to achieve performance levels once thought possible only with high-end plastics. Nanomodified polycarbonate exhibits improved resistance to UV radiation and scratching, extending product lifespan in demanding environments like automotive glazing, electronics housings, and optical lenses.

These nanofillers interact at the molecular level, restricting polymer chain movement and improving load transfer, which leads to greater impact resistance and reduced creep under mechanical stress.

Such developments confirm that nanotechnology is not an abstract concept but a tangible driver of material performance.

For manufacturers across Europe’s coatings, resins, and polymers supply chain, this means that nanotechnology is no longer an experimental add-on—it is quickly becoming a competitive necessity.

The ability to enhance performance with minimal loading rates gives producers a powerful commercial advantage: they can deliver higher-value materials without fundamentally altering production lines or increasing costs disproportionately.

For SMEs in particular, nanomodified additives and fillers offer a way to differentiate products, enter higher-margin market segments, and meet tightening performance and sustainability standards demanded by downstream industries. As nanomaterials continue to mature and scale, the businesses that invest early—whether through sourcing advanced additives, co-developing nanocomposites, or integrating nanotech into existing product portfolios—will be best positioned to capture new demand and secure long-term resilience in an increasingly innovation-driven raw materials market.

To learn more about how nanotechnology can improve coatings, resins, and polymers, visit POLYMER NANO CENTRUM, or contact info@polymernanocentrum.cz.