Nanoparticles Create Dissolvable Polymer Composites

Is this the beginning of reversible/re-mouldable polystyrene or epoxy resin?

Industry takes full advantage of composite polymer materials to create adhesives, epoxy resins, coatings, and fillers which are strong and durable. They function as joining materials, protective barriers, and floorings for everyday materials like wood, metal, and concrete. Yet they all carry one inherent problem: once they have set, they have set forever.

But they may all be about to change as nanotechnology has found a way to create simple polymers that can function as strong and stable raw materials in a set form, such as polystyrene, which can later be dissolved and reused.

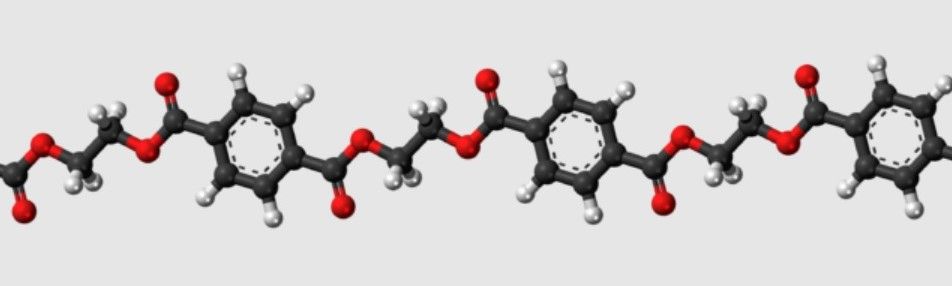

Led by nanotechnology researchers from Lawrence Berkeley National Laboratory (Berkeley Lab) the discovery is described as a method for engineering pseudo-bonds in polymers such that the chains of molecules entangle in a completely reversible manner. This enables nanomaterial specialists to combine the robust chemical connections which give epoxies and other composites their strength with the ability to reverse the bond and reuse the material.

Related articles: Turning Graphene into a Printable Ink for Manufacturing or Nanotechnology Provides Custom-Made Raw Materials

The conventional approach to manufacturing tough and durable polymer composites is to add a setting agent which creates a network of molecules which are crosslinked together with permanent chemical bonds.

Alternatively, longer chains of polymer molecules are used in a tangled knot which cannot be untied. By analysing the way tangled balls of proteins are used in nature, the team was able to find a reversible design for long chains of the polymers used in manufacturing.

“This is a brand-new way of solidifying materials,” explains Prof. Ting Xu, one of study’s lead authors. “We open a new path to composites that doesn’t go with the traditional ways.”

As the Berkeley Lab press release explains, “The researchers attached polystyrene chains to hundred-nanometers-diameter silica particles, to create what Xu dubbed ‘hairy particles.’ By forming nanocomposites, these hairy particles self-assembled into a crystal-like structure, providing different spaces between each unit for the hairy polymers to fill. The space available to each polystyrene chain depended on its position in the structure—and, therefore, determined how much it tangled together with its neighbors.”

By limiting the polymer chains to minuscule areas with distinct geometries, the team was able to restrict the movement of the polymer chains. This gave the researchers a level of control over how entangled they were, or more significantly, were not. Then, when the researchers formed a loose arrangement of polystyrene chains they were able to apply a force which would further loosen the knot entirely.

“How much entanglement happens with the particles determines their response to an external force,” explains Xu.

Furthermore, the nanomaterial specialists found that they could modify the structure's response to external forces by varying the size of the polystyrene chains and the exact location and number of chains attached to each facet of the silica particle. It is these parameters which form the secret to creating the ‘pseudo bonds’ which enable reversible polymer composites.

The study has now been published in the journal Advanced Materials.

“Let’s say you have a ball of yarn, and it’s a mess. You can’t untangle it,” says Xu. “But if you play with the yarn, maybe you can trick it to untangle.

While this may all sound complex to the man on the street, to nanomaterial scientists it is a relatively straightforward process, such that the researchers are confident that it can be applied to other polymers and even to an industrial scale. To date, their work has focused on polystyrene as it is one of the most common polymers in industry, while silica is a low-cost nanoparticle. However, the team are now looking to see how other industrial composites, such as epoxies, will respond.

Nanotechnology-enabled polymer composites that can be reversed back to their original states hold immense potential in a wide range of practical applications. These innovative materials, including coatings, epoxy resins, and polymer fillers, could offer unprecedented versatility as it would allow them to be reset or reused elsewhere without compromising their structural integrity.

In the automotive and aerospace industries, for example, self-healing coatings and reusable composite components could reduce maintenance costs and prolong the lifespan of critical parts. In construction, reversible polymer fillers can simplify repairs and renovations, while in electronics, reconfigurable polymer-based circuits could enhance device recyclability and reduce electronic waste.

Elsewhere, these advanced composites could even be employed in packaging and medical devices, where temporary, adaptable, and reusable materials are highly valuable.

The ability to reverse and repurpose polymer composites not only promotes sustainability but also opens up new possibilities for novel product designs across various industries. As nanotechnology research continues to advance, the integration of such materials into mainstream manufacturing will further revolutionize industry and contribute to a more circular economy.

Photo credit: Atlascompany on Freepik, Freepik, Wikimedia, NANO CHEMI GROUP, & Flickr