Nanocellulose & Its Role in the Polymer Industry

Where plant power meets polymer performance at the nanoscale.

As the plastics industry strives to balance sustainability with performance, plant-based raw materials are gaining increasing attention. In the field of advanced polymer design, this shift is driving interest in nanocellulose as a promising bio-based alternative.

Cellulose is a natural carbohydrate (a type of polysaccharide) made up of long chains of glucose molecules which is found wood, cotton, paper, and almost all other plants. It is the main structural component of the cell walls, giving plants their rigidity and strength.

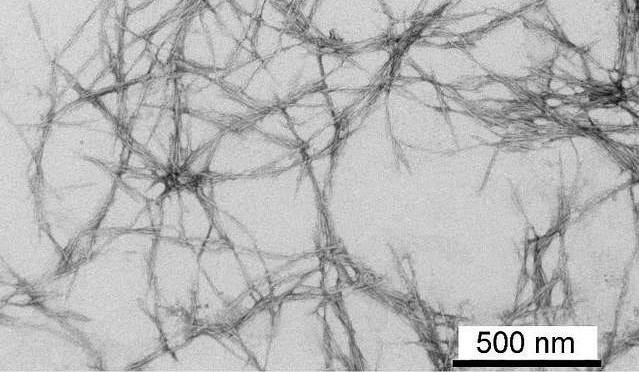

Nanocellulose refers to cellulose particles that have been processed to the nanoscale—typically 5–100 nanometres in diameter and several hundred nanometres in length, where a human hair is about 100,000 nm thick. There are several types, including:

· Cellulose nanocrystals (CNCs) – rigid, rod-like particles.

· Cellulose nanofibrils (CNFs) – long, entangled fibrils.

· Bacterial nanocellulose (BNC) – produced by certain microbes.

What is attracting the manufacturing sector to these raw materials is the way that they combine low weight, biodegradability, and high mechanical strength—all while being derived from renewable resources such as wood pulp or agricultural waste. These properties make it ideal for reinforcing polymers, replacing synthetic additives, and enhancing barrier performance.

1. Nanocellulose-Based Emulsions & Polymer Additives

One promising industrial application is in Pickering emulsions—emulsions stabilised by solid particles instead of conventional surfactants—as nanocellulose excels in this role, offering strong interfacial stability.

This has practical benefits for manufacturers using polymer dispersions, coatings, adhesives, and even food-contact packaging. For example, the application of nanocellulose allows for reduced surfactant usage which improves a product’s eco-toxicity profile and allows for a reduced regulatory burden. Emulsion-based adhesives made with nanocellulose may also have an increased shelf life and improved mechanical strength when compared to their regular counterparts.

Furthermore, by stabilising these polymer systems more effectively, nanocellulose also helps streamline processing—lowering energy demand and waste.

2. Reinforcing Polymers with Nanocellulose

Adding nanocellulose to thermoplastics or thermosets significantly improves mechanical properties—without the weight or brittleness typical of traditional mineral fillers. Common gains include:

· Higher tensile strength and Young’s modulus.

· Better dimensional stability.

· Enhanced thermal resistance.

For example, Stora Enso, a Finnish/Swedish company which produces biomaterials, packaging, and paper, has introduced cutting‑edge nanocellulose‑based coatings and biocomposites that act as high-performance alternatives to traditional plastics in packaging. This includes a product line which blends wood fibres including nanocellulose with bio-based or recycled polymers. The result is a plastic product which is used to create injection‑moulded components such as caps, closures, and packaging inserts.

Not only do these nanocellulose composites deliver strong mechanical properties and excellent tactile performance while reducing fossil plastic content by up to 98 %, but they can even be integrated into existing moulding processes with minimal changes yet with applications ranging from luxury cosmetics packaging to food-grade containers.

Nanocellulose is also known to perform well in bio-based polymers like PLA or PHA, supporting the transition to more sustainable materials without sacrificing durability.

3. Industrial-Scale Benefits for Manufacturers

The transition from traditional polymer blends to nanomodified systems brings several bottom-line advantages, such as superior material properties (reduced breakage, better thermal resistance, and improved UV or chemical resistance), customisation (nanocellulose additives can be tailored to end-use, e.g. fire retardancy, conductivity, transparency), and process efficiencies (with less filler required, lower weight-to-performance ratios, and potential savings in curing or mixing stages).

From a commercial perspective, adopting nanocellulose-enhanced polymers opens opportunities for product differentiation, cost reduction, and regulatory readiness—especially for industries facing increasing pressure to reduce environmental impact.

4. Sector-Specific Applications

The potential of nanocellulose spans many industries, these include:

· Packaging: Films with nanocellulose offer superior oxygen and moisture barriers—ideal for food and pharma. Transparent coatings with antimicrobial features are also in development.

· Construction: Polymer-concrete blends using nanocellulose show better crack resistance and longevity, such that they are already being applied in facade panels and modular structures.

· Electronics & Adhesives: Nanocellulose in epoxy resins supports thermal management and electrostatic discharge control, critical for electronics assembly.

· Composites for Mobility: Lightweight, high-strength parts for cars or aircraft can benefit from nanocellulose-reinforced polymers—cutting fuel use and material cost.

Related articles: Pioneering Polymer Nanostructuring for Real-World Innovation or How Nanoparticles Enable Biodegradable UV Protection

As global industries pivot towards more sustainable and high-performance materials, nanocellulose stands out as a transformative solution. Derived from abundant, renewable plant sources, it offers a compelling blend of lightweight strength, biodegradability, and functional versatility. Whether enhancing the mechanical properties of polymers, stabilising advanced emulsions, or enabling next-generation composites, nanocellulose is not only reshaping polymer science—but also redefining how manufacturers approach innovation, regulation, and sustainability.

As commercial-scale production becomes more accessible, the question is no longer if nanocellulose will play a role in future materials development, but how quickly and where it will deliver the greatest impact.

Photo credit: Picryl, Flickr, GaryStockBridges, & Freepik