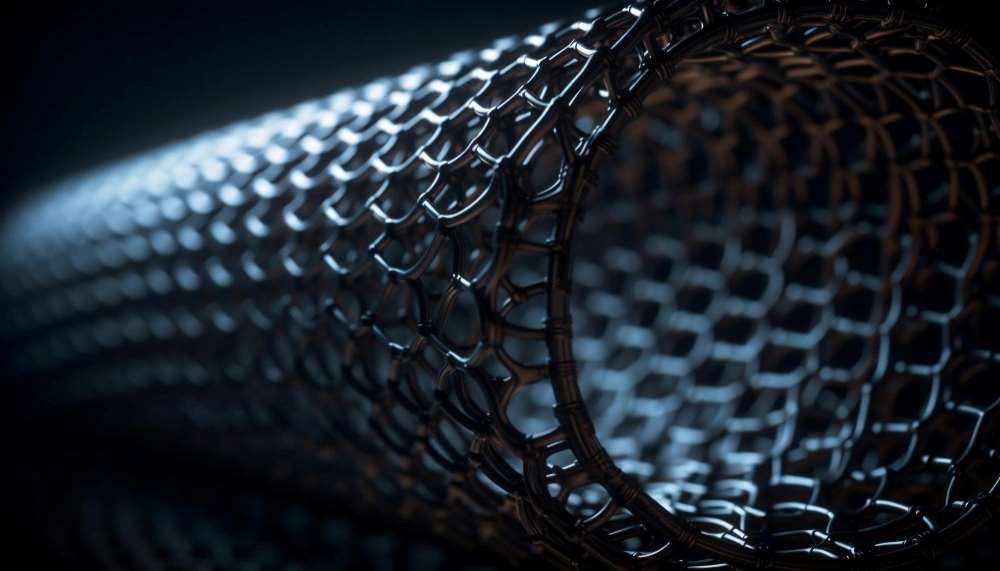

Nano-scale Reinforcement for Multifunctional Polymers

How nanomaterial-polymer composites can provide EMI shielding, conductivity, and flexibility.

New research on the use of nanoscale-reinforcement—whether carbon nanotubes, graphene, or other advanced fillers—has once again demonstrated how lightweight polymer matrices can be transformed into conductive, protective, and multifunctional materials.

This time the latest breakthrough has been made in South Africa by nanotechnology researchers from the Council for Scientific and Industrial Research (CSIR) who have unveiled a nano-reinforced polymer composite that combines high electrical conductivity with outstanding electromagnetic interference (EMI) shielding. For industries ranging from defence to medical technology, this represents a major step forward.

“This collaboration marks a significant step forward in South Africa’s materials science capabilities,” explains Professor Suprakas Sinha Ray, Chief Researcher and Centre Manager: DSTI-CSIR Nanotechnology Innovation Centre. “The nano-reinforced composite not only outperforms traditional materials but also opens doors for local innovation in critical industries such as aerospace, electronics, and healthcare.”

Specifically, the nanomaterial-polymer composite could have real-world uses in the defence industry, where stealth technology is used to lower radar signatures in aircraft, drones, and defence equipment. In civilian industry, the polymer could be applied to create radar-absorbent infrastructure to shield communication hubs and sensitive facilities, or in protecting advanced sensors which rely on electrical conductivity and responsiveness to electromagnetic fields.

It could also be used in medical implants, where a conductive yet biocompatible material is needed for next-generation pacemakers or neural interfaces.

Such versatility reflects the growing role of nanotechnology in polymers—where one carefully engineered additive can unlock multiple functions.

Key to the success of nanotechnology in polymer engineering is the ability of nanomaterials to provide plastics with multifunctionality. Unlike conventional polymers, which are typically insulators, nanomaterial composites offer multiple unique-selling points and advantages:

· Superior EMI shielding in critical c- and X-band frequencies.

· Enhanced radio-frequency absorption, enabling stealth and protection.

· Exceptional electrical conductivity for safer products.

· Processing flexibility, as nanoadditives are available as granules for extrusion and injection moulding or as filaments for additive manufacturing.

These combinations mean the same material can move seamlessly from a factory floor to a 3D printer, without losing its advanced properties.

Additionally, the breakthrough is a major leap forward for South Africa, as this nanotech composite showcases a leap in materials science capability and positions the country as a contributor to the global advanced materials market.

Here in Europe, similar work is underway on EMI shielding nanocomposites and nano-enhanced 3D printing filaments. POLYMER NANO CENTRUM, for example, has multiple cooperation agreements with material research institutes and scientists in academia, as well as its own nanotechnology research centre which has been specifically designed for innovating industrial polymers for business.

For SMEs in the Czech Republic and across the EU, nanotechnology research is raising exciting possibilities for adopting nano-reinforced composites for high-value applications, as well as collaboration opportunities between international R&D centresand European manufacturing.

The CSIR nano-reinforced polymer composite being a case study in how nanotechnology can make polymers multifunctional. It demonstrates the power of cross-disciplinary collaboration, and the practical potential of nanotech to deliver solutions in defence, electronics, healthcare, and manufacturing.

The POLYMER NANO CENTRUM blog page follows such developments closely. Inspiring the company’s mission to harness the full potential of nano-enabled polymers.

Alternatively, if you would like to know more about how POLYMER NANO CENTRUM (who sponsor this webpage) can improve polymer products through the smart integration of nanotechnology to provide electrical conductivity, EMI shielding, UV protection, scratch resistance, chemical protection, or thermal conductivity then contact info@polymernanocentrum.czor visit POLYMER NANO CENTRUM.

Photo credit: Raw Pixel, kjpargeter, Vecstock on Freepik, & wirestock