Nano-Biocomposites: Their Properties and Applications Explained

Is the future of polymers is both bio-based and nano-enhanced?

Nano-biocomposites are hybrid materials that combine biopolymers such as cellulose, chitosan, alginate, or polyhydroxyalkanoates with nanoscale additives like clays, silica, or carbon nanotubes. These materials are gaining attention due to their potential to address key challenges in polymer science: sustainability, enhanced functionality, and biocompatibility. As industries move towards greener solutions, nano-biocomposites stand out as versatile materials for packaging, healthcare, environmental, and industrial applications.

But what exactly are nano-biocomposites? What properties do they possess? Where can they be applied? And what role will they play in the polymer industry of tomorrow?

Definition & Key Properties

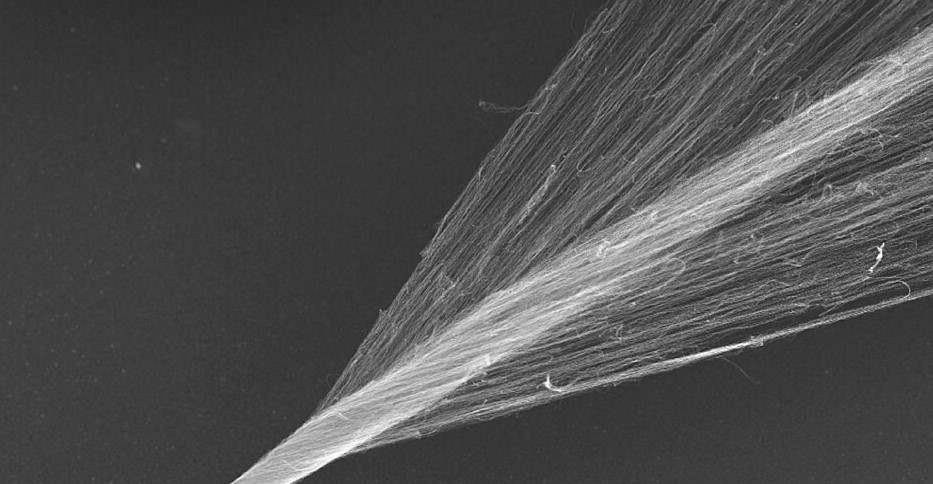

Nano-biocomposites are matrix materials (such as resins, biopolymers, natural fibres etc.) which contain nanomaterial additives measuring less than 100 nanometres (1mm = 1,000,000nm). As these nanomaterials are so small, they have a significantly increased surface area to volume ratio which allows them to efficiently interact with the conventional raw materials surrounding them. This nanoscale design can improve mechanical, thermal, and barrier properties beyond those of conventional biopolymers.

Key enhancements include:

· Mechanical: Higher stiffness, tensile strength, and durability.

· Thermal: Improved heat resistance and stability.

· Barrier: Reduced permeability to oxygen, carbon dioxide, and moisture.

· Biological: Added bioactivity, including antimicrobial and bioactive properties.

For example, a polylactic acid (PLA) can more than double its tensile modulus through the incorporation of nanocellulose whiskers. Similarly, adding nanoclay to starch films can reduce their oxygen permeability, extending the shelf life of packaged food.

Raw Materials & Components

Cellulose, chitosan, alginate, starch, collagen, gelatin, and polyhydroxyalkanoates are all common bases due to their biodegradability and renewability.

Meanwhile, the most widely used nanoscale additives include montmorillonite clays, silica nanoparticles, carbon nanotubes, titanium dioxide, zinc oxide, and reduced graphene oxide. These nanofillers are used to improve mechanical and thermal performance while in some cases also providing antimicrobial or UV-resistant functions.

Due to the wide availability of raw materials and the way in which nanotechnology can modify these inputs to enhance specific properties, the range of applications for nano-biocomposites in industry is vast, but includes:

1. Packaging & Food Preservation

Enhanced Barrier and Mechanical Properties. Nano-reinforced films (e.g., PLA, PBAT, starch, cellulose derivatives) with nanoclays (montmorillonite, layered silicates) drastically improve gas and water vapor barrier capabilities, mechanical strength, thermal resistance, and optical clarity.

As a recent review on the topic published in the journal Progress in Polymer Science notes, “Nanocomposites have high potential applications in the food packaging sector as an innovative packaging materials with new functional properties that can better protect the quality and safety of food.”

Active & Intelligent Packaging. Nano-biocomposites are also used in ‘active’ packaging to provide antimicrobial, antioxidant, ethylene or moisture scavengers, which eliminates the need for sachets. They can even enable intelligent packaging that reacts to spoilage or environmental conditionsby reacting to gases emitted from food as it ages.

For example, chitosan films embedded with curcumin-loaded porous silica nanoparticles have been found to provide pH-responsive sustained-release antimicrobial activity against E. coliand S. aureus. Further innovative antimicrobial films, such as starch-lignin nanoparticle composites have shown UV protection, thermal stability, reduced oxygen permeation, and antioxidant capacity to delay lipid oxidation.

2. Agriculture & Food Processing

Nanocarrier Delivery of Agrochemicals. In the field of agriculture, nano-biocomposites from chitosan, alginate, cellulose, and starch are being used as slow-release carriers of fertilizers, nutrients, or pesticides—boosting crop yields and minimizing environmental runoff.

Additionally, nano-coatings and nano-films can function as protective layers to enhance seed germination, shield against pathogens, and extend the shelf life of produce while also being biodegradable.

As a review in the journal Frontiers, notes, “Biopolymers (e.g., chitosan, alginate, fibrin, and hyaluronic acid) play a remarkable role in the absorption of water (biopolymer-based hydrogels, super absorbent) in soil and can also be used as slow-releasing nanocarriers for the delivery of agrochemicals to plants (fertilizers/nutrients) and also for treating pathogens (fungicides, bactericides, virucides) and pests (pesticides).” Continuing to explain the advantages in that, “The release of agrochemicals is slowed down drastically as a consequence, and the leaching of the agrochemicals into the soil and aquatic ecosystem minimized.”

3. Electronics & Advanced Materials

Packaging for Flexible Electronics. Biodegradable polymers like PLLA, PVA, PBAT reinforced with nanolayers (OLDH, montmorillonite, graphene oxide) have shown enhanced mechanical strength, optical clarity, and water vapor barrier capabilities.

Furthermore, nano-biocomposites have also been proven to provide EMI-shielding and electro-conductivity.

4. Automotive, Construction & Composites

Superior industrial feedstocks. Biocarbon from non-food agricultural waste has been used in thermoplastic composites (substituting carbon black or glass fibre). These biobased composites are currently being trialled by Ford, GM, Volkswagen, and Tesla for automotive components.

Other studies have found that reinforcing PLA with cellulose nanocrystals (CNCs), nanofibrils (CNFs), or microcrystalline cellulose (MCC) can improve mechanical performance while retaining biodegradability. This makes them suitable for lightweight structural parts and sustainable construction materials across the automotive sector.

5. Adhesives & Specialty Materials

Eco-Alternatives to Super Glue. Cellulose nanocrystals have been turned into highly directional ‘eco-glue’—an adhesive stronger along one plane (as much as seventytimes stronger) yet is easily removable by touch if pressure is applied in a different direction. Due to their low cost, sustainability, and high performance, these adhesives are ideal for delicate electronics, reusable assembly, and packaging, or simply if a greener alternative to conventional adhesives is required.

6. Biomedical & Healthcare

Drug Delivery, Imaging & Anticancer Therapies. Biopolymer-based nanocomposites are widely researched for controlled-release drug delivery, targeted anticancer treatment, bioimaging, and antimicrobial wound dressings. For example, cellulosic wound dressings incorporating allantoin-layered zinc hydroxide have displayed effective antimicrobial activity against S. aureus.

Tissue Engineering Scaffolds. Additionally, engineered nano-biocomposite scaffolds have been used to mimic the natural extracellular matrix.

Nano-biocomposites are emerging as one of the most promising classes of sustainable materials, bridging the gap between natural polymers and advanced nanotechnology. Their ability to combine biodegradability with enhanced performance positions them as strong candidates for replacing or supplementing conventional plastics across packaging, agriculture, healthcare, construction, and electronics.

This success is due to their versatility, where the same principles of nanoscale reinforcement that can improve barrier properties in food films can also be harnessed to engineer scaffolds for tissue regeneration or lightweight composites for automobiles.

While large-scale adoption still depends on overcoming challenges of cost, scalability, and regulatory approval, the trajectory is clear—companies are increasingly investing in bio-nanocomposites as industrial feedstocks.

As consumer demand for greener products rises and legislative pressure against traditional plastics intensifies, bio-nanocomposites stand at the forefront of sustainable polymer science. Offering a unique combination of sustainability, performance, multifunctionality, and a step towards a more circular, bio-based future for polymer manufacturers.

If you are interested in learning more about how nanomaterials can impact and improve raw materials for the manufacturing sector, visit POLYMER NANO CENTRUM.

Photo credit: Wikimedia, Flickr, Flickr, Flickr, Freepik, & Kelly Thomas on Pixnio