Inside the Polymer Nano Centrum Laboratory – Part 2

How one company is turning nanotechnology research into real-world polymer solutions.

In Part 1, the analytical and characterisation techniques used at POLYMER NANO CENTRUM were outlined—methods that reveal a polymer’s composition, structure, and behaviour. However, understanding a material is only the beginning. To create practical improvements, insights must be transformed into new formulations, tested for durability, and validated under conditions that reflect real-world use.

This is where the processing, durability testing, and pilot-scale equipment at POLYMER NANO CENTRUM’s laboratory plays a crucial role, as these tools allow nanotechnology to move beyond theory and into production-ready solutions for polymer manufacturers.

1. Compounding and Processing: Incorporating Nanotechnology Effectively

Introducing nanomaterials into polymers requires precise control. Even small variations in dispersion or mixing can lead to inconsistent results. At POLYMER NANO CENTRUM, this is achieved through specialised compounding and processing equipment:

· Micro-compounders and twin-screw extruders are used to blend polymers with nanoparticles, nanoscale additives, and modifiers under controlled conditions. The micro-compounder enables small-scale testing of new formulations using minimal material, while the twin-screw extruder can handle a wide range of throughputs, from laboratory-scale batches to pilot-scale production.

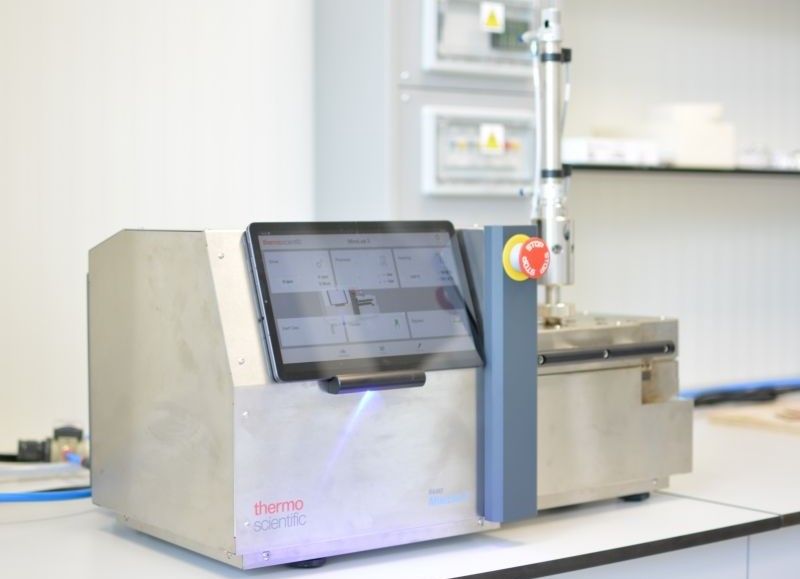

· Capillary rheometers and Melt Flow Index (MFI) measurements are then employed to ensure that the modified material maintains suitable processing characteristics for extrusion, moulding, or film production.

By verifying processability early, manufacturers can adopt enhanced materials without costly disruptions to their existing production lines.

2. Shaping and Forming: Creating Realistic Samples

To evaluate performance properly, materials are shaped into representative products. There are several systems in place to achieve this, including:

· Compression presses capable of applying forces up to 600 kN and reaching temperatures of 300 °C are used to produce test specimens, laminates, or sheet materials.

· A blown film line allows thin films to be produced under pilot-scale conditions, enabling a practical assessment of barrier properties, mechanical strength, and appearance.

· Ultrasonic generators and centrifuges support the preparation of dispersions and coatings, ensuring uniform distribution of nanoparticles in liquid or semi-liquid media.

These facilities make it possible to move seamlessly from laboratory formulation to prototype product.

3. Durability and Environmental Testing: Ensuring Real-World Reliability

A polymer may perform well initially, but long-term durability often determines commercial success. To predict service life and compliance with demanding industry standards, the following tests can be performed:

· Corrosion chambers simulate harsh conditions such as salt spray, condensation, and cyclic humidity—critical for automotive, marine, and outdoor applications.

· UV exposure systems (UV BOX) replicate the effects of sunlight, moisture, and rain, accelerating weathering tests to assess colour stability, cracking resistance, and mechanical retention over time.

· Dynamic Mechanical Analysis (DMA) and other thermal tests are integrated to examine changes in mechanical properties during and after environmental exposure.

This combination of testing ensures that enhanced materials are not only innovative but also dependable in the conditions they will face in service.

4. Bridging Laboratory Innovation and Industrial Production

The advanced processing and testing facilities at POLYMER NANO CENTRUM allow nanotechnology-based enhancements to be developed with a clear route to implementation. In this way, manufacturers can benefit from early identification of potential processing challenges, access prototype-scale validation without disrupting production, and have the confidence that new materials will withstand real-world environments.

By providing this bridge between laboratory research and industrial manufacturing, POLYMER NANO CENTRUM enables polymer producers to integrate nanotechnology in a controlled, cost-effective, and commercially viable manner.

A Partner for the Next Generation of Polymers

Nanotechnology is reshaping what polymers can do—creating materials that are lighter, stronger, and more functional than ever before. Yet for many manufacturers, accessing this potential requires specialised expertise and equipment that cannot be justified in-house.

Through its comprehensive facilities and applied research focus, POLYMER NANO CENTRUM offers a practical solution: enabling companies to explore, test, and adopt nanotechnology without taking unnecessary risks.

For polymer businesses seeking to stay competitive, collaboration with nanotechnology experts provides a clear path from established know-how to next-generation innovation.

To learn more about how nanotechnology can improve polymer products, contact info@polymernanocentrum.cz or visit POLYMER NANO CENTRUM.

Photo credit: POLYMER NANO CENTRUM