How to Implement Nanotechnology into Existing Products

Modernising industrial coatings, resins, and polymers with performance-based differentiation.

Across Europe’s coatings, resins, and polymers sector, competition is becoming increasingly defined not by scale, but by performance. Markets that once rewarded high-volume, low-margin production are now shifting toward materials that deliver measurable, verifiable value. End-users—from automotive OEMs to construction suppliers and electronics manufacturers—are demanding coatings, resins and polymers that last longer, perform better under stress, and support sustainability objectives.

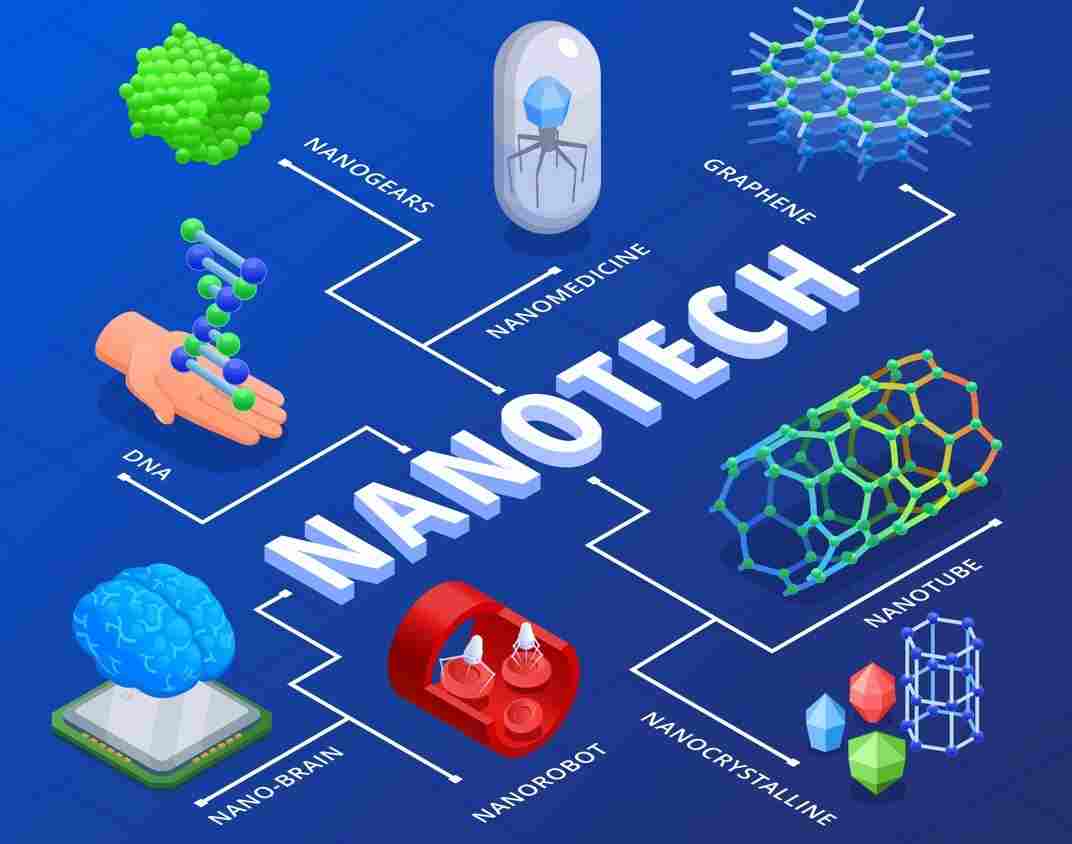

Nanotechnology is emerging as one of the most commercially significant tools enabling this shift. By enhancing traditional materials with nanoscale additives, manufacturers can unlock properties that simply aren’t achievable with conventional formulations—greater toughness, higher UV stability, improved corrosion resistance, electrical conductivity, or advanced functionalities such as self-cleaning or thermal regulation. Importantly for manufacturers, these enhancements not only elevate product performance but also open the door to premium pricing and stronger differentiation in a market historically driven by cost.

For producers, manufacturers, and raw material distributors looking to modernise their portfolios, nanotechnology provides a practical pathway to move up the value chain. It allows companies to transition from commodity suppliers to solution providers, delivering raw materials that solve specific industry challenges. Enabling manufacturers to move beyond price-driven competition towards performance-based differentiation.

Strategic Actions for Manufacturers of Coatings, Resins, and Polymers

To translate the potential of nanotechnology into commercial success, manufacturers should consider a structured approach following a step-by-step plan like this:

1. Audit existing products.

Identify coatings, polymers, or resins which could benefit from measurable performance improvement—such as improved wear resistance, UV protection, or reduced weight.

2. Collaborate strategically.

Form partnerships with nanomaterial suppliers or experts, such as the research team at POLYMER NANO CENTRUM, who specialise in surface chemistry and polymer modification. With their own specialist research centre just outside Prague, POLYMER NANO CENTRUM (who sponsor this webpage) have constructed a laboratory purpose-built for the development of nanotechnologies for the polymer industry.

By supplying the team with a wish list of performance enhancements, the researchers will analyse how to provide them with the application of nanotechnology.

3. Start with pilot projects.

At this point, a sample run or pilot product will be produced to test dispersion behaviour, compatibility, and most importantly, performance metrics.

4. Model the economics.

Calculate the cost of nano-additives against potential price premiums or lifetime savings for end-users. Even a modest performance improvement can justify a higher price. Some manufacturers have even found that the inclusion of nanomaterials in a product actually lowers input costs by replacing large quantities of bulk raw materials.

5. Develop a narrative.

Position your company as a provider of “next-generation” or “performance-driven” products. Customers are increasingly willing to pay for materials that combine sustainability with advanced functionality.

By adopting these measures, SMEs can transition from commodity suppliers to technology partners, capturing higher margins while contributing to the broader industrial shift toward advanced materials.

In practical terms, this means the next generation of coatings and resins will offer multiple integrated functionalities—self-healing, thermal regulation, anti-corrosive protection, and even energy harvesting. Demand will grow across sectors that require durability under extreme conditions, from renewable energy infrastructure to electric vehicles and aerospace.

Sustainability will also remain a core driver. Nanotechnology allows for lighter, stronger materials that reduce energy use and extend product life, aligning with the EU’s broader environmental objectives. As regulation tightens around volatile organic compounds (VOCs) and material waste, nano-enabled resins and coatings can help manufacturers meet compliance targets while maintaining performance.

The key will be balancing innovation with pragmatism—adopting technologies that deliver real, verifiable advantages without overextending resources.

Nanotechnology is transforming the coatings, resins, and polymer industries from the ground up. What began as a scientific curiosity has evolved into a commercial reality that is redefining performance standards across industrial applications.

The path forward for manufacturers lies in combining technical awareness with strategic foresight. By integrating nano-enhanced materials into product portfolios, collaborating with innovators, and positioning themselves as partners in performance and sustainability, SMEs can move beyond the price competition towards products with added value.

The next frontier in industrial coatings, resins, and polymers will belong to those who think small—at the nanometre scale—but still act boldly enough to think big.

To identify how nanotechnology can be integrated into their existing product lines in a practical, commercially viable way, companies can request cooperation with POLYMER NANO CENTRUM.

By beginning with a clear list of desired performance improvements—such as enhanced hardness, UV resistance, conductivity, or reduced material weight—producers can brief the centre’s research team, who then evaluate the most suitable nanomaterials and modification methods.

Using their purpose-built laboratory near Prague, POLYMER NANO CENTRUM conducts controlled trials, formulates prototype samples, and analyses dispersion, compatibility, and mechanical behaviour to ensure that the nano-enhanced material will perform reliably at industrial scale.

This collaborative model allows manufacturers to de-risk innovation, leverage specialist expertise they may not have in-house, and accelerate the development of next-generation coatings, resins, and polymers that meet both technical and market demands.

To learn more about how to proceed, visit POLYMER NANO CENTRUM or contact info@polymernanocentrum.cz.

Photo credit: POLYMER NANO CENTRUM, Macrovector, Pikisuperstar, & kjpargeter on Freepik