How Raman Spectroscopy Helps Make Better Polymer Composites

Understanding polymer composites is more than just price and market trends, it means knowing the internal science of raw materials.

Most polymer engineers are familiar with conventional additives: pigments, stabilisers, or carbon black used to strengthen or colour plastics. In recent years, however, a new class of additives has emerged—nanomaterials.

These new industrial feedstocks, such as graphene, carbon nanotubes (CNTs), and graphite nanoplatelets are so tiny they often measure just a few nanometres thick. Yet even at very low loading levels they can bring big advantages in both reduced costs and boosted functions.

For example, adding as little as 0.5 wt.% of carbon nanomaterials to a polymer can significantly increase stiffness and tensile strength, making plastics tougher without adding weight. Alternatively, a small amount of nanotubes can create conductive pathways, turning an insulating polymer into one that can dissipate heat or carry electrical current. Nanomaterial additives can also improve a polymer’s gas resistance, impact strength, or even chemical and UV resistance.

Related articles: Navigating Nanofiller Regulations for Polymers or Inside the POLYMER NANO CENTRUM Laboratory – Part 1

The result is smarter, stronger polymer composites that open up applications in lightweight automotive parts, specialised coatings and resins, or packaging with improved performance.

The Challenge: What’s Really Happening Inside?

Adding nanocarbons to polymers may sound straightforward, but achieving these property enhancements is not guaranteed, with a few key issues often determining success:

· Dispersion – Are the nanomaterials evenly spread out or clumped together?

· Interface – Do they bond well with the polymer matrix, or are they loosely embedded?

· Orientation – In fibres or films, are the nanomaterials aligned to reinforce in the right direction?

Traditional tools like microscopy can show us surface features or large aggregates, but they don’t reveal what’s happening at the molecular level. To truly understand how the nanocarbon is behaving inside the polymer, we need a technique that can ‘listen in’ on the structure of the material itself.

That’s where Raman spectroscopy comes in.

Raman Spectroscopy—A Simple Introduction

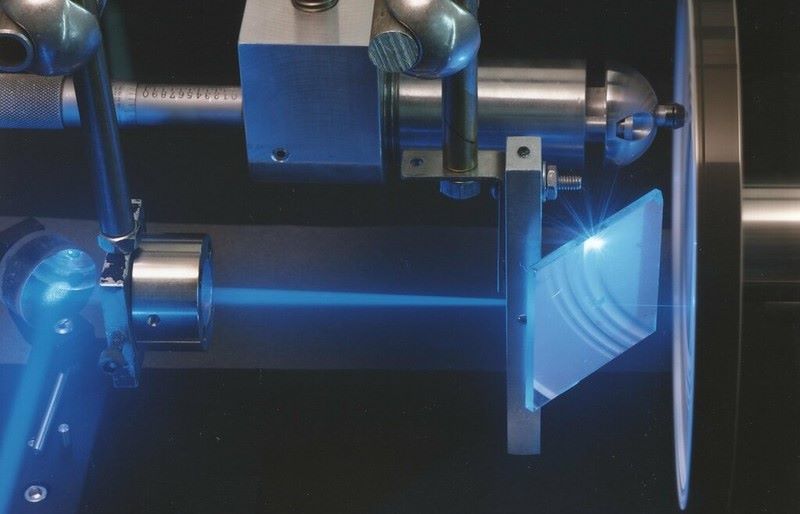

Raman spectroscopy may sound intimidating, but the principle is simple. A laser beam is directed at a material, and while most of the light bounces back unchanged, a tiny fraction shifts in energy because it interacts with molecular vibrations. Measuring these shifts gives us a spectrum—a kind of molecular fingerprint.

For carbon-based materials, Raman is particularly powerful. Carbon atoms arranged in graphitic structures (like in graphene and CNTs) respond strongly to Raman light, meaning they can be detected even when only a trace amount is present in a polymer.

In practice, this means a Raman spectrum is not just abstract peaks—it’s a direct readout of structural information, such as order, defects, and bonding.

As the AZO Optics industry journal explains, “The position of Raman peaks is directly influenced by the strength of chemical bonds and the masses of the atoms involved. Stronger bonds and lighter atoms produce higher vibrational frequencies, resulting in peaks at higher Raman shifts, while weaker bonds and heavier atoms lead to lower-frequency vibrations.”

This is especially useful when studying carbon nanomaterials within a polymer. As AZO Optics notes, “Analyzing intensity ratios between Raman peaks enables assessment of structural differences, molecular orientation, and phase composition within a sample. These ratios offer comparative information, particularly useful for identifying polymorphs, monitoring crystallinity, or evaluating relative concentrations in mixtures.”

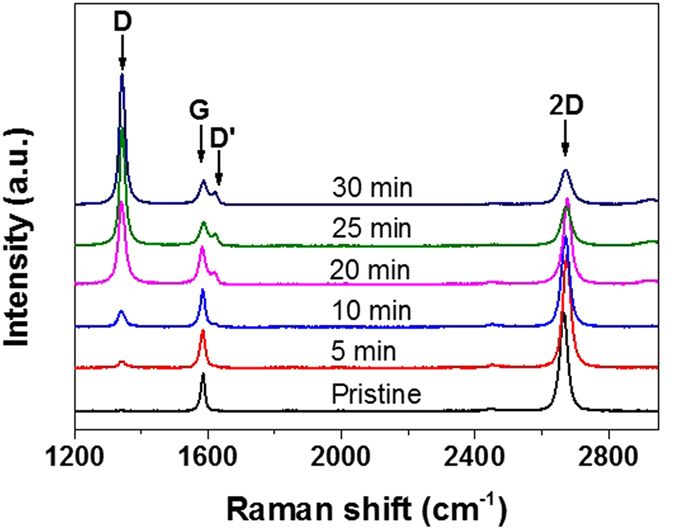

While understanding the readings from a Raman spectroscopy analysis is a highly skilled process, when looking at carbon nanomaterials, three Raman ‘markers’ are especially important:

· G-band (~1580 cm⁻¹) – Linked to carbon–carbon bonds in ordered graphitic structures. Strong G-peaks suggest well-organised graphene or CNTs.

· D-band (~1350 cm⁻¹) – Associated with defects or disorder. A strong D relative to G means the material has imperfections or has been chemically modified.

· 2D-band (~2700 cm⁻¹) – An overtone of the D-band that provides clues about the number of graphene layers and the quality of the crystal lattice.

By comparing these peaks, Raman can tell whether the material is pristine graphene, multi-layer graphite, or nanotubes, and whether it is highly ordered or riddled with defects.

Even better, these features can still be detected inside a polymer composite—so Raman doesn’t just analyse the filler in isolation, it can probe how it behaves once mixed in.

Raman Spectroscopy as a Tool for Polymer Manufacturers

For polymer manufacturers, Raman spectroscopy results give immense insights into how nanomaterial additives are impacting a polymer and how the polymer composite will function as a product. For example, the Raman value can inform a polymer engineer on some or all of the following:

· Identifying the filler – Are you working with graphene, graphite, or CNTs? Raman spectra make it clear.

· Checking dispersion – By scanning across a sample, Raman mapping shows whether the nanofiller is spread evenly or clumped.

· Evaluating bonding – Shifts in peak positions or changes in the D/G ratio reveal how strongly the nanomaterial interacts with the polymer.

· Measuring stress transfer – When a polymer composite is stretched, the Raman peaks shift, showing whether stress is effectively passed from polymer to filler.

· Studying orientation – Using polarised Raman, one can measure whether nanotubes or platelets are aligned within fibres or films.

For polymer engineers, the attraction of carbon nanomaterials lies in their promise: big improvements in strength, conductivity, and durability for only a small addition of feedstock.

Raman spectroscopy then gives polymer manufacturers a practical way to monitor these factors at every stage—whether during research and development, scaling up production, or quality control of finished composites. It is a non-destructive, sensitive, and surprisingly accessible tool that directly links material structure with polymer performance.

As carbon nanomaterials continue to move from laboratory curiosity to industrial workhorse, tools like Raman spectroscopy are becoming essential companions. They provide the insight needed to turn the potential of nanomaterials into reliable, market-ready performance improvements by enabling better, smarter, and more competitive polymer composites.

Located just outside Prague, the facility (which sponsors this webpage) has been designed solely for studying how nanotechnology can improve industrial raw materials for polymers, coatings, and resins.

To find out more about how POLYMER NANO CENTRUM can boost industrial products and specialist feedstocks, contact info@polymernanocentrum.cz or visit POLYMER NANO CENTRUM.

Photo credits: Wikimedia, Flickr, POLYMER NANO CENTRUM, & POLYMER NANO CENTRUM