Carbon Nanomaterials Proven 100% Recyclable

Nanotechnology researchers find that carbon nanomaterials do NOT lose properties after recycling.

In the modern manufacturing landscape, the importance of recyclability has taken centre stage – even when it comes to nanomaterials.

As these innovative raw materials find their way into composites, pharmaceuticals, cosmetics, coatings, and even textiles—enhancing performance and durability across various industries—their environmental impact cannot be overlooked. The shift towards a circular economy means that a deeper understanding of how nanoscale components interact within composite structures is required. Even more important, is knowing how they can be recycled and what, if any, functionality is lost.

With this in mind, material researchers and nanotechnology specialists are beginning to look into what happens when nanomaterials are recycled, with results that are both ‘surprising’ and expected to have ‘far-reaching implications for manufacturing across sectors.’

“Recycling has long been a challenge in the materials industry,” says Prof. Matteo Pasquali, a corresponding author on the study. “Metals recycling is often inefficient and energy intensive, polymers tend to lose their properties after reprocessing and carbon fibers cannot be recycled at all, only downcycled by chopping them up into short pieces.”

But what about carbon nanotubes (CNTs)? Can they be recycled without losing any of their inherent desirable properties, such as strength and electrical conductivity?

“We expected that recycling would be difficult and would lead to significant loss of properties,” he adds. “Surprisingly, we found that carbon nanotube fibers far exceed the recyclability potential of existing engineered materials, offering a solution to a major environmental issue.”

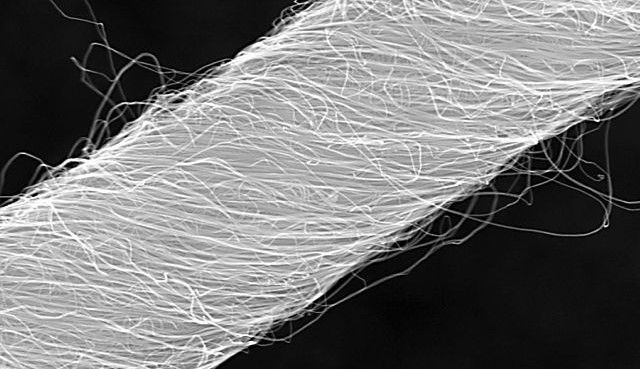

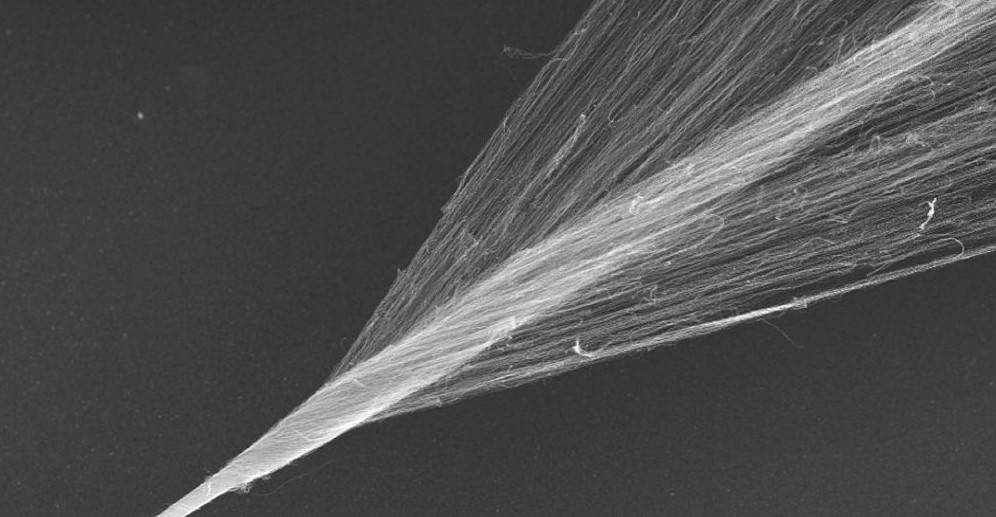

For their experiments, the researchers used chlorosulfonic acid, a common industrial solvent, to dissolve fibre-grade commercial CNTs to form a solution made of spun CNT fibres. This was done as it was important to measure the recyclability of materials with different fibre qualities and CNTs made from different processes. Much like plastics recycling, it is thought that CNT recycling will come from mixed sources and a variety of end-of-life products.

“By using two different sources of carbon nanotubes, we ensured that our recycling process was representative of real-life conditions,” explains Michelle Durán-Chaves, a graduate student who worked on the project. “Remarkably, the recycled fibers demonstrated equivalent mechanical strength, electrical conductivity, thermal conductivity and alignment, which is unprecedented in the field of engineered materials.”

Despite starting with a mixed source of ‘waste’ CNTs, once dissolved and re-spun, the recycled nanomaterial retained the same structure and alignment as virgin material.

“This preservation of quality means CNT fibers can be used and reused in demanding applications without compromising performance, thus extending their lifecycle and reducing the need for new raw materials,” notes Dr Ivan R. Siqueira, who co-authored the research.

The effectiveness of the recycling process for nanomaterials has also shocked industry in the efficiency of how carbon nanomaterials can be recycled. Unlike conventional metal and polymer recycling techniques, which require high energy consumption, dangerous chemicals, or time-consuming sorting, CNTs can be recycled with a straightforward process of dissolving and re-spinning.

“The ability to fully recycle CNT fibers has broad implications for industries like aerospace, automotive and electronics,” notes Durán-Chaves. “We hope this could pave the way for fully recyclable composites in aircraft, vehicles, civil infrastructures and more, ultimately reducing environmental impacts across a wide range of sectors.”

You can learn more about this profound research on the YouTube video produced by Rice University. Or you can also discover more about how carbon nanomaterials can make cost savings, improve product quality, or provide unique selling points, by visiting POLYMER NANO CENTRUM.

POLYMER NANO CENTRUM runs Central Europe’s only nanotechnology research centre dedicated entirely to manufacturing. The company (which hosts this webpage) is an innovative Czech business focused on the application of nanotechnology in polymers, where unique nanostructuring technologies suitable for industry are developed.

Call +420 233 371 850 or email info@polymernanocentrum.cz to find out more.

Photo credit: Flickr, Flickr, Wikimedia, ResearchGate, & Wikimedia