Can Nanotech Turn Wood into An Electric Generator?

How nanotechnology can turn wood into an electrically conductive raw material for use as a generator, transistor, or battery.

Wood is well-known as an excellent insulator against electrical charge. So why are some researchers looking to employ it as an electrically conductive raw material?

Despite its insulating properties, when wet, wood can actually generate tiny amounts of charge – and when modified with nanomaterials or chemicals it can even be powerful enough to light up a light-emitting diode (LED).

This discoverywas made by Jonas Garemark, a PhD student at Sweden’s KTH Royal Institute of Technology, who is now theorising how much wood is needed to power other small electrical devices or even household appliances.

Wood as a Battery?

“You can put wood on even more steroids with additives,” says Yuanyuan Li, a professor of fibre and polymer technology at KTH and Garemark’s PhD adviser. For example, the pair have already found that wood impregnated with iron oxide nanoparticles and then soaked in water can generate more than 165 times the current of ordinary wet wood.

“As long as it’s in water, the electricity doesn’t stop,” Li says. “This can be a feasible battery for low-power devices, especially for remote areas. You could make it at home.”

At a simple description, wood is made up of three polymers: hemicellulose, cellulose, and lignin. When these three building blocks are combined wood is strong. But thanks to their intricate arrangement they also possess not only the ability to store and transport an electrical charge, but also the power to generate tiny quantities of electricity.

By skilfully utilising chemical engineering to customise the components and microscopic properties of wood, these nanotechnologists have been able to create sophisticated electrical devices, including energy generators, energy storage devices, and even transistors—the switch-like components that create logic circuits.

Wood as a Generator?

Given the progress made in developing ever-smaller electronics and with the expected birth of the Internet of Things, using sustainable wood in place of more expensive metals could create a world where wooden batteries, biodegradable sensors, and power-generating wooden floors are commonplace. Opening a wooden door, for example, could power the light in the room, as could walking across floorboards, climbing the stairs, or opening and closing a drawer.

“Wood is a natural, renewable, widespread, and carbon-sequestering material,” observes Guido Panzarasa, a chemical scientist in the wood materials science laboratory at ETH Zurich. “Until recently, it was used almost exclusively for structural and decorative purposes. We want to use wood to make electricity, to conduct electricity, and to use electricity.”

The key to this breakthrough field is in understanding the nanotechnology.

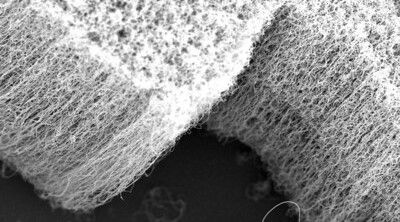

At the nanoscale, wood is made up of thousands of aligned nanofibres which form bundles that are bound together by lignin and then wrapped in hemicellulose. The grain of a wood is a result of these micrometre-wide, porous fibres being interspersed with long tubes called lumen, which help the plant to transport water from the roots to the leaves.

The similarity between many nanomaterials (such as carbon nanotubes) and the cellulose nanofibres in wood has already been noticed by many nanotechnology researchers. Liangbing Hu, for instance, is a material scientist at the University of Maryland who decided to remove the lignin from wood and then open up the intricate tube system to chemical modification.

“The tiny fibers had very similar dimensions [to carbon nanotubes], and their properties were similar too,” he recalls. “That’s why I got very excited about this material.”

It is also where nanotechnology theory becomes the reality of wood generating electricity.

“When the researchers soak a thin slice of wood in a sodium hydroxide–based electrolyte and sandwich it between platinum electrodes,” reports the scientific journal CE&N reports, “a little heat applied to one electrode generates electricity as the sodium ions from the electrolyte move through the cellulose chains. Such devices could scavenge low-level heat from machines or even from the human body to produce power.”

Wood as a Transistor

A further approach to using wood to generate electricity is by squeezing the nanofibres together. As they are formed in bundles with a highly organised crystalline structure (similar to that found in quartz and ceramics), they are piezoelectric materials. This means that when pressure is applied the material is deformed, but its movement generates an electrical current.

Other nanotechnology researchers are examining how to use wood’s structure as a scaffold that could be filled with highly conductive nanomaterials.

Doing so has enabled Isak Engquist and his colleagues at Linköping University to create the world’s first wooden transistor.

This was achieved by removing some of the lignin from a piece of balsa wood and then sandwiching a thin slice of polymer-coated wood between two slightly wider pieces of wood, before adding an electrolyte gel at the cross point.

When an electrical current is applied to the wider pieces, a chemical reaction turns the polymer from a conductive to a non-conductive material. By turning the current off, the polymer returns to its conductive state – forming a transistor.

“The conducting polymers perform well when they are configured as a network of fibers,” Enquist explains. “The wood structure provides a template which offers exactly that.”

Alongside the very small current, the wood’s natural variations make the transistor unsuitable for use outside of a lab, but the proof-of-concept provides a great deal of hope for those hoping to see sustainable natural materials, such as wood, used as conductive raw materials.

Wood electronics could be especially useful in things that are meant to be disposable, such biomedical or environmental sensors that properly decompose after usage. Simplicity and aesthetics are also crucial, as it could replace bulky batteries and generators with wood electronics built into energy-producing parquet flooring, wood-based sensors integrated directly into structural beams, and wooden panels that regulate gadgets.

But on a commercial scale, by attempting to transport electrons through wood, a classic insulator, nanomaterial researchers are not just being innovative. They are defying the laws of nature to enhance raw materials in ways that provide manufacturers with desired properties and unique selling points.

Photo credit: Flickr, Freepik, Vecstock on Freepik, Freepik, Wikimedia, Flickr, & Adam from Pixabay