Boosting Strength, Cutting Costs: Nanotech in Green Polymers

How nanomaterials are giving bio-based plastics an affordable, competitive advantage.

The global polymer sector is entering a period of structural change. Customer requirements are shifting, regulations are tightening, and the pressure to demonstrate sustainability credentials is intensifying across all industries. Yet the challenge for most manufacturers has remained the same: how to offer greener raw materials without compromising mechanical strength and durability or increasing input and production costs.

Now a recent academic review is suggesting that a realistic answer is emerging in the science of nanotechnology.

The paper, published in the November 2025 edition of the journal Frontiers in Materials brings together the latest advances in bio-based polymers reinforced with nanoscale fillers and highlights how manufacturers of specialised polymer products can develop high-performance, sustainability-oriented materials without major capital disruption.

What are Green Polymer Nanocomposites?

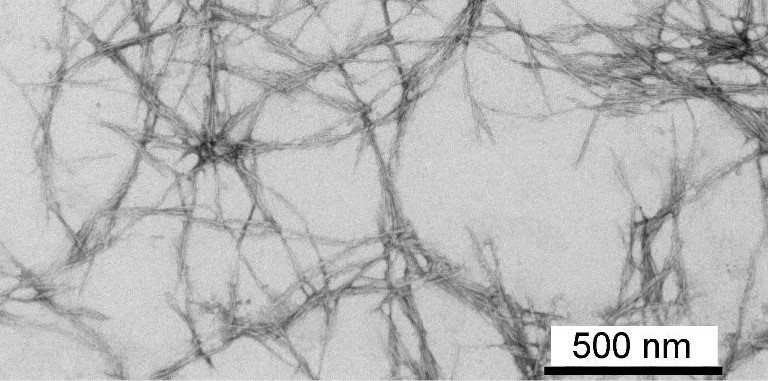

At their core, green polymer nanocomposites combine bio-based polymers with nanoscale fillers to achieve performance characteristics previously associated with conventional petrochemical-based plastics. The polymer matrices explored in the November review include PLA, PHA, cellulose, starch, chitosan, and alginate—materials already familiar to producers involved in bioplastic packaging, biodegradable films, or natural-fibre composites. These are combined with nanofillers such as nanoclay, bio-derived nanofibres, nano-biochar and carbon-based nanomaterials to gain clear market advantages without lowering prices and with minimal input costs.

In some cases, input costs can even be reduced as nanofillers replace conventional feedstocks at a lower price.

While on a kilo-for-kilo basis, nanomaterials are more expensive, they outperform conventional feedstocks in many ways. This means that kilo-for-kilo they can add more strength, durability, flexibility etc. and so can replace traditional inputs at a reduced overall cost.

The key industrial appeal lies in how these nanotechnology-fillers interact with the polymer matrix. At the nanoscale, surface area increases significantly, allowing improved energy transfer and stronger interfacial bonding. This not only enhances quality but also reduces the filler quantity needed to achieve the same mechanical performance. For manufacturers focused on margin protection, the ability to enhance a polymer’s barrier-properties, chemical resistance, flexibility, electro-conductivity, durability, UV-resistance, and strength with less raw material is important.

How does Nanotechnology Improve Green Polymer Performance?

One of the most striking outcomes of the review is the scale of performance enhancement achieved with relatively modest nanofiller additions. In several studies, nanofillers improved tensile modulus by 60–70 per cent compared with the base polymer. Hybrid-filler systems—those combining, for example, nanoclay with cellulose nanofibres or biochar—achieved increases in elongation at break of up to 200 per cent.

Barrier properties are also a major point of interest. Nanoclay, in particular, creates tortuous paths for gas and moisture transmission, which significantly reduces permeability. According to the review, these barrier improvements are sufficient to challenge certain multilayer packaging structures that have long been regarded as difficult to replace. For manufacturers supplying the packaging, coatings, and protective-film sectors, this opens the possibility of offering films or coatings with high functional performance while simultaneously meeting sustainability objectives.

Related articles: How to Implement Nanotechnology into Existing Products or Nanotechnology is Going Mainstream for Industry

The study makes clear that these developments are substantial in bringing bio-based materials closer to, and sometimes surpassing, the performance range of conventional engineering polymers.

Commercial Advantages in Nanotech for Polymer Manufacturers

Perhaps the most important message for industry is that green nanocomposites do not require a fundamental change in manufacturing equipment or process infrastructure. Twin-screw extruders already used for masterbatch production are entirely suitable for compounding many forms of nanofillers.

Furthermore, the introduction of nanofillers also creates opportunities for new product lines. As technical markets—such as automotive interiors, durable consumer goods, and high-barrier flexible packaging—are increasingly searching for materials that combine sustainability with certified performance, bio-based masterbatches reinforced with nanomaterials offer a route for polymer manufacturers to command higher margins.

Additionally, energy savings may also prove meaningful, as several nanofiller-reinforced polymers can be processed at slightly lower melt temperatures than their conventional counterparts, offering incremental reductions in per-tonne energy consumption.

Supply-Chain Considerations

Like any emerging technology, polymer nanocomposites bring new supply-chain dependencies. Nanoclay, fortunately, remains abundant, competitively priced, and widely available from established suppliers. Carbon-based nanomaterials, though historically expensive, are gradually decreasing in price as both the range production methods and applications in industry expands.

Dispersion quality remains one of the largest variables in commercial viability. Nanoscale fillers agglomerate easily, which increases the risk of defects and performance inconsistency. However, advice and product analysis from nanotechnology experts, such as POLYMER NANO CENTRUM (who sponsor this webpage) can ensure that formulas and processes are developed to maintain product quality.

Like previous academic reviews on the potential of nanotechnology in the polymer industry, this latest November 2025 study demonstrates convincingly that green polymer nanocomposites are not simply an academic curiosity. Moreover, they represent a practical, commercially relevant avenue for polymer manufacturers to achieve stronger market position by offering sustainable products with properties that match or surpass their fossil fuel-based counterparts.

Manufacturers that integrate nanomaterials into bio-based polymers can also reduce long-term input costs, lower energy requirements, and meet the increasingly strict sustainability expectations of regulators and global brand owners.

In a market where differentiation is tightening and margins are under pressure, nanotechnology is rapidly becoming a force for growth by empowering bio-based polymers to perform better at a lower cost.

Photo credit: Ryan Quintal on Unsplash, Lilik Eka, picryrl, Wikimedia, & Pxhere