Beyond Kevlar: Nanotech for Bulletproof Polymer Fibres

Science can now create nanocomposite polymers which balance protection, low-weight, and flexibility.

For decades, Kevlar has been the gold standard in personal protection and high-performance composites. Its strength, lightness, and resistance to impact have made it indispensable in body armour, aerospace components, and industrial applications.

Yet this 50-year-old technology has its limits: it can be brittle under extreme stress, degrades under UV exposure, and requires energy-intensive manufacturing. With material science continuing to push the limits of polymer design, a new generation of materials is beginning to surpass even Kevlar’s remarkable capabilities.

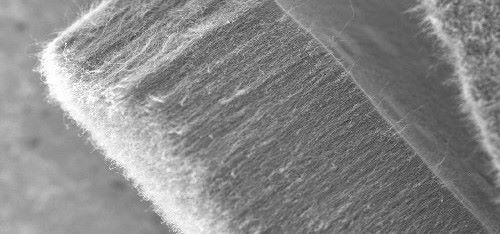

This is because nanomaterial researchers have developed a bulletproof fibre that is stronger, tougher, and thinner than Kevlar — a nanotechnology discovery that could redefine how we think about polymer performance and protection. Reported in a recent study in the journal Cell, this new material combines nanostructured precision with advanced polymer chemistry to achieve mechanical properties once considered impossible.

The secret lies at the nanoscale, where polymer chains are engineered to form ultra-ordered crystalline regions interwoven with flexible amorphous phases. This forms a structure which mimics natural materials such as spider silk—tough yet flexible, and capable of dissipating energy without breaking.

Laboratory tests show that this nanomaterial composite outperforms Kevlar and ultra-high-molecular-weight polyethylene (UHMWPE), both in tensile strength and in toughness. As a report on the discovery published in the journal Phys.org notes, “The scientists subjected their new material to high-speed tests, including ballistic tests similar to those used for body armor. It achieved a dynamic strength significantly higher than existing fibers, and its ability to absorb energy more than doubled the previous record, reaching 706.1 megajoules per cubic meter.”

The nanocomposite is also thinner and lighter, making it easier to weave into flexible textiles or integrate into composite panels. Importantly, the synthesis process may be more energy-efficient and potentially compatible with recyclable precursors—a step towards making high-performance polymers more environmentally friendly.

While the new bulletproof fibre is still in the research phase, future work is planned, focusing on optimising properties such as flexibility, water resistance, and multi-impact durability — properties which are key for bulletproofing in real-world conditions.

For manufacturers, the implications are wide-ranging, as nanocomposite polymers such as this could be used not only in personal protective equipment (helmets, vests, gloves) but also in aerospace, automotive, and construction sectors where lightweight, impact-resistant composites are in high demand. Integrating the fibre into additive manufacturing or smart textile production could even open up entirely new product categories.

While commercialisation of this specific application of nanomaterials will depend on overcoming challenges in cost and international certification. However, its development signals a broader transformation in polymer science: from improving known materials to designing entirely new molecular architectures.

As the study’s authors themselves conclude, “Our study not only presents an effective strategy for the fabrication of aramid fibers with ultra-high dynamic strength as well as the highest recorded dynamic toughness, but also provides fresh mechanism insights.”

For whatever happens to this nanotechnology on the market, the direction is clear: the fusion of nanotechnology and polymer chemistry is opening new frontiers in strength, sustainability, and smart functionality.

The evolution from Kevlar to nano-engineered polymers represents more than a technical improvement — it marks a shift in mindset. A new way to look at manufacturing issues by focusing on the nanomodification of polymers. Because, by controlling matter at the molecular level, nanotechnology researchers can now create materials that balance protection, low-weight, and flexibility.