A Nanotech Breakthrough in Long-Term Antibacterial Coatings

The smart application of nanomaterials is now creating long-life cleanliness.

The fight against bacterial contamination has long relied on silver. For centuries, this precious metal has been valued for its antimicrobial properties, but its use in modern medicine and industry has always come with drawbacks. Traditional silver-based coatings tend to release ions too quickly or too unevenly, reducing their effectiveness over time and sometimes causing unwanted side effects.

Now, researchers at the University of Manchester’s National Graphene Institute have pioneered a new approach that could redefine antibacterial surface protection. By combining graphene oxide membranes with silver nanoparticles, the team has created a coating capable of delivering silver ions in a controlled and long-lasting manner.

“Our research represents a paradigm shift in antimicrobial coating technology,” said Professor Rahul Nair, co-lead of the study. “By harnessing the unique properties of graphene oxide, we have unlocked new possibilities for creating coatings that provide long-term protection against bacteria.”

Silver has been widely used in medical devices, wound dressings, and hygiene-sensitive applications because of its strong antibacterial action. However, the challenge lies in controlling the release of silver ions. Conventional coatings often discharge them in a rapid burst, leading to three fundamental issues:

· Short-lived effectiveness: once the silver is depleted, the antibacterial effect fades.

· Potential toxicity: high local concentrations of silver ions can harm surrounding tissue.

· Sustainability concerns: large amounts of silver are required to maintain performance.

This has limited the broader adoption of silver coatings, despite their potential to reduce infections and contamination.

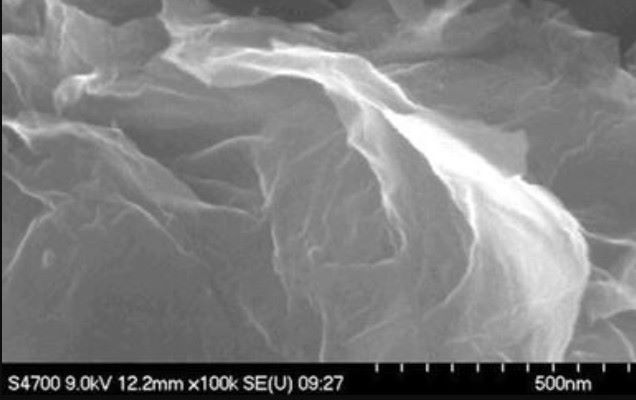

Graphene oxide, a derivative of the nanomaterial graphene, provides an elegant answer to this problem, as its layered nanostructure contains channels that can act as filters, controlling how and when silver ions pass through. Instead of a single uncontrolled burst, the ions are released gradually, ensuring that antibacterial activity is maintained over an extended period.

“This approach allows us to deliver just the right amount of silver for extended protection,” explains Dr Swathi Suran, the study’s first author. “It not only enhances the effectiveness of antimicrobial coatings but also minimises the potential risks associated with silver overexposure.”

This ‘smart release’ mechanism marks a significant step towards coatings that are safer and more efficient. It also underlines nanotechnology as one of the most cost-effective ways to enhance regular products with boosted properties—in this case antimicrobial power.

The possible uses of this technology are wide-ranging, but have obvious applications in healthcare where nanomaterial-based coatings are already used in:

· Wound dressings, offering longer-lasting protection against infection.

· Medical implants, reducing the risk of bacterial colonisation.

· Hospital equipment, where durable antimicrobial surfaces are essential.

Beyond medicine, the technology could also find roles in engineering and manufacturing, particularly in hygiene-critical areas such as food processing, water systems, and consumer products. The ability to create coatings with a long service life and reduced silver consumption also bring both economic and environmental benefits.

Not only has this breakthrough captured the attention of nanotechnology specialists, but it is also resonating with manufacturers. The concept of controlled release holds particular promise for producers of polymers, coatings, and composite materials, offering a pathway to enhanced performance and greater efficiency. Graphene oxide membranes exemplify this potential, showing how nanostructured materials can boost the functionality of raw materials while cutting costs—most notably by optimising the use of valuable metals like silver, making processes both more economical and sustainable.

Innovations like these also resonate with broader trends in advanced materials research — where the goal is not simply to add functionality, but to integrate it intelligently within polymer systems.

This is a key part of the work being conducted at POLYMER NANO CENTRUM, where a uniquely equipped, privately owned nanotechnology centre in the Czech Republic is pushing the boundaries of what's possible at the nanoscale.

Related articles: How Nanoparticles Enable Biodegradable UV Protection or Nanotechnology: The New Force in EM Wave Shielding

Since 2016, POLYMER NANO CENTRUM (which funds this website) has grown into a hub of innovation, assembling a team of multidisciplinary experts and equipping its Rakovník facility with state-of-the-art instrumentation—including Raman and FTIR spectrometers, capillary rheometers, particle size analysers, extrusion compounders, and more—to enable precision design and modification of polymers at the atomic level.

The company now offers a range of patented nanostructuring solutions and commercial products—such as nanomaterial concentrates for epoxies, polyesters, and polycarbonates—that systematically enhance electrical, mechanical, thermal, UV-resistant, and chemical properties of base polymer systems, achieving improved performance, durability, and sustainability.

If you would like to know more about how POLYMER NANO CENTRUM can help manufacturers reduce costs, improve products, or become more sustainable with the use of raw materials, then contact info@polymernanocentrum.cz or visit POLYMER NANO CENTRUM.

Photo credit: Freepik, Mark Stebnicki on Pexels, Pikisuperstar, & Wikimedia