7 Ways Nanomaterials Can Improve Polymer Products

Discover the unique-selling points and cost savings which nanomaterials can provide to industrial polymers.

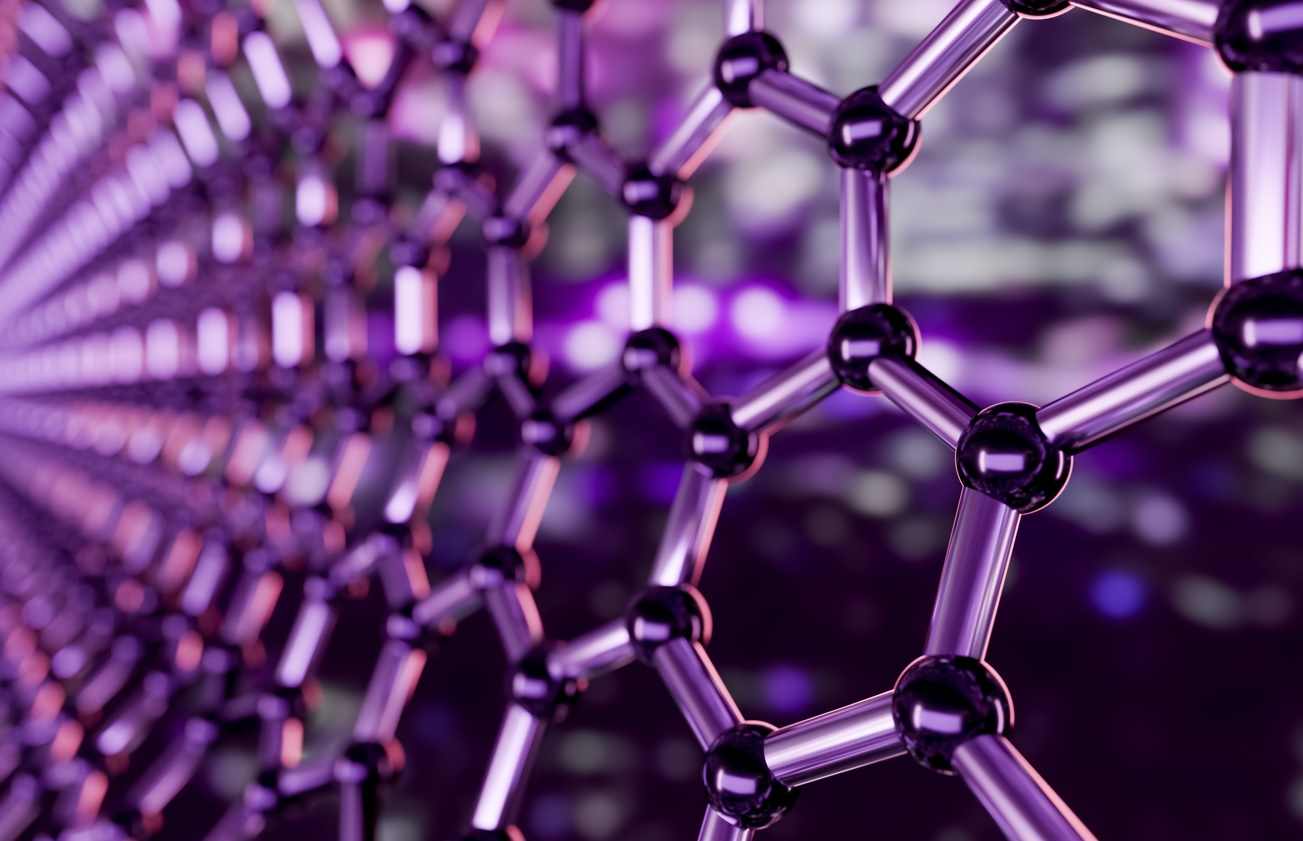

Incorporating nanomaterials into polymers has revolutionized material science, leading to the development of polymer nanocomposites with enhanced properties. These advanced materials exhibit superior mechanical strength, thermal stability, electrical conductivity, and chemical resistance compared to traditional polymers.

While this field of science is constantly advancing, it has already established itself as a useful industrial feedstock. Here are some of the most popular ways that manufacturers are reducing production costs or finding unique-selling points by using nanomaterials as a raw material in their polymer products.

Enhanced Mechanical Properties

One of the most significant advantages of integrating nanomaterials into polymers is the improvement in mechanical properties. This is achieved by using nanoparticles such as graphene and carbon nanotubes as reinforcing agents in conventional plastics, polymers, and coatings. By adding these nanoparticles at low concentrations (~0.2 weight %) the flexibility and compressive mechanical properties of polymer composites can be significantly improved. Furthermore, because of the exceptionally low concentration, the polymers original characteristics can still be maintained.

These enhancements are possible only through the accurate blending of the nanoparticles in the polymer mix, this effectively restricts polymer chain mobility and improves load transfer efficiency.

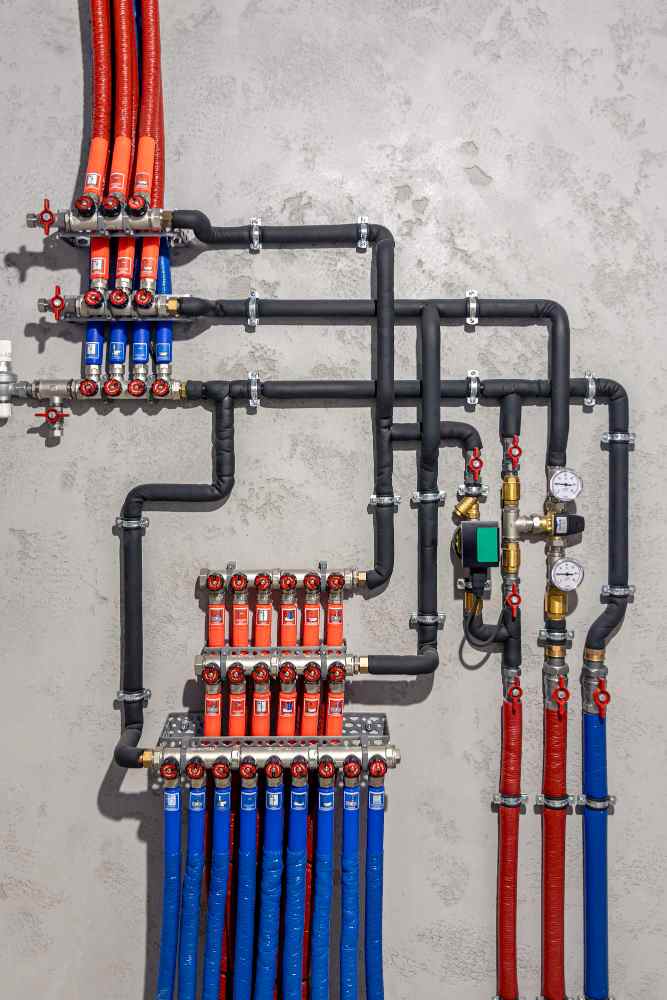

Thermal Stability

Polymers requiring thermal stability are essential in industries where materials are exposed to elevated temperatures, harsh conditions, or thermal cycling. These polymer products can be found in the automotive and aerospace industries (such as in engine components and lightweight body parts), in the electronics sector (circuit boards, insulation, and heat sinks), in construction materials (thermal insulation panels, fire-resistant coatings, and sealants for doors and windows), the packing industry (which uses heat-sealable films and temperature-resistant containers), and industrial chemical production (heat resistant pipes, tubing, gaskets, and coatings).

Nanomaterials can significantly enhance the thermal stability of polymers through the following mechanisms:

· Heat Shielding: Nanomaterials such as clay, silica, or metal oxides form a protective barrier on the polymer surface, shielding it from heat and delaying thermal decomposition.

· Char Formation: Some nanomaterials promote the formation of a stable, carbon-rich char layer when exposed to high temperatures. This char acts as an insulating layer that protects the underlying polymer from heat and oxidation.

· Enhanced Crosslinking: Nanoparticles can facilitate crosslinking within the polymer matrix, making it more thermally stable and less prone to degradation.

· Reduced Polymer Mobility: The incorporation of nanoparticles restricts the mobility of polymer chains, lowering the tendency of the polymer to break down at elevated temperatures.

· Catalytic Stabilization: Certain nanoparticles can catalyse reactions that lead to the formation of more stable structures, enhancing thermal resistance.

Electrical Conductivity

The integration of nanomaterials, such as carbon nanotubes or graphene, into polymer matrices allows their electrical conductivity to be dispersed throughout the composite. This property is particularly beneficial in products which require antistatic or electromagnetic interference shielding. Often these conductive properties can be applied in coatings which are now available in off-the-shelf products or can be designed-to-order to provide specific degrees of electrical conductivity as required for specialist applications.

Chemical Resistance

Nanomaterials can enhance the chemical resistance of polymers, making them suitable for use in harsh chemical environments. For instance, chemically resistant paint is designed to protect surfaces from corrosive substances, thereby extending the lifespan of the underlying material. These coatings are used inside chemical facilities, when mining caustic substances, or in other chemically toxic environments.

Flame Retardancy

Nanocomposites have also been developed which can add fire resistance or flame retardancy through their insertion inside unfilled polymer matrices. By embedding nanoparticles like clay, carbon nanotubes, or metal oxides, the thermal decomposition of the polymer can be delayed, reducing combustibility.

This fire retardancy can be achieved through several mechanisms, including:

· Barrier Formation: Some nanomaterials, like layered silicates or clay nanoparticles, form a protective char layer on the surface when exposed to high temperatures. This char acts as a barrier that insulates the underlying material from heat and oxygen, slowing down combustion.

· Gas Phase Inhibition: Certain nanomaterials release substances that dilute combustible gases produced during polymer decomposition, reducing flame propagation.

· Heat Shielding: Metal oxide nanoparticles, like aluminium oxide or magnesium hydroxide, can absorb and dissipate heat, lowering the polymer’s surface temperature and slowing ignition.

· Enhanced Char Formation: Nanomaterials can promote the formation of a stable, carbon-rich char that acts as a physical barrier, reducing the release of flammable gases.

· Catalytic Decomposition: Some nanoparticles catalyse the decomposition of polymers into less flammable or non-volatile products, reducing the risk of ignition.

By including nanomaterials during manufacture, polymer-based fire safety products can be significantly improved without compromising their mechanical properties. Alternatively, they can be added to products to provide fire resistance or flame retardancy without compromising the polymer’s original function.

Barrier Properties

The inclusion of nanomaterials in polymers can significantly improve their barrier properties against gases and liquids. This enhancement is crucial for packaging applications where the prevention of oxygen or moisture ingress is essential. The high aspect ratio of certain nanomaterials can block or restrict gas molecules, thereby reducing permeability and enhancing a material's protective capabilities.

Cost Savings for Polymer Manufacturers

Nanomaterials used as an industrial feedstock into polymers can result in substantial cost savings for manufacturers, as by enhancing mechanical, thermal, and chemical resistance properties, manufacturers can use smaller quantities of conventional raw materials.

For example, tyre manufacturers have been able to reduce the amount of carbon black used in their products by including nanomaterials which achieve the same or even better performance—resulting in lower raw material costs.

Additionally, the improved durability and lifespan of nanocomposite products mean fewer replacements and reduced maintenance expenses. By investing in nanomaterial-enhanced polymers, manufacturers can achieve long-term economic benefits while delivering superior quality products.

The incorporation of nanomaterials into polymers represents a transformative leap in material science, offering unparalleled enhancements to mechanical strength, thermal stability, electrical conductivity, chemical resistance, flame retardancy, barrier properties, and cost savings. These improvements are not just theoretical but have practical applications across a wide range of industries.

As the field of nanocomposite research continues to advance, the potential for even more innovative and resilient materials becomes increasingly promising.

This means that today, investing in nanomaterial-enhanced polymers is more than just a technological upgrade—it is a strategic move toward sustainable, high-performance raw materials that can meet the demands of modern manufacturing.

Photo credit: Pvproducts on Freepik, NANO CHEMI GROUP, Cookie studio, Freepik, pvproducts, & Macrovectors