5 Polymers that Will Change the World

Can you name the five polymer products which will have the greatest impact on manufacturing?

Polymers have been a cornerstone of modern civilization, from the early plastics used to make basic household items, like kitchenware, to more advanced polymer composites, such as the Kevlar used in body armour.

Even the ubiquitous marvel that is the smartphone is manufactured from a variety of polymers such as thermoplastic polyurethane (TPU), polymethyl methacrylate (PMMA or Acrylic), polyethylene terephthalate (PET), acrylonitrile butadiene styrene (ABS), and good old polycarbonate (PC).

But as the world faces mounting environmental and technological challenges, a new generation of polymers is emerging as smarter, stronger, and more sustainable feedstocks for manufacturing than conventional plastics. In the next 20 years, these five cutting-edge polymers are poised to reshape industries, from medicine to construction, and from travel to communication.

Modern polymers will redefine what’s possible in a more sustainable future, and here’s how.

1. Polylactic Acid (PLA) 2.0 – The Biodegradable Workhorse

While polylactic acid (PLA) has been around for years as a compostable alternative to petroleum-based plastics, it’s about to get a serious upgrade. This is because new formulations of PLA are overcoming its drawbacks of brittleness and heat sensitivity, making it suitable for automotive parts, electronics, and even structural components.

Moreover, with advances in biocatalysis and fermentation, PLA production is becoming more efficient and less reliant on food crops, easing sustainability concerns. Consequently, experts are predicting that enhanced PLA will become the standard for packaging, disposable goods, 3D printing, and medical applications—replacing legacy plastics in high-volume products without environmental guilt.

NatureWorks, for example, is a leading manufacturer of PLA biopolymers in Asia; a company which is significantly expanding its production capabilities to meet the growing global demand for sustainable materials. The company’s growth is centred on the construction of a new, fully integrated PLA manufacturing facility in Thailand designed to produce 75,000 tons of biopolymer annually with full production expected to commence in late 2025.

2. Nanomaterial Additives – Giving Polymers Desired Properties

Thanks to advances in nanotechnology, material scientists can now manipulate nanoparticles to alter how they react with other materials—changing their intrinsic properties for something new. Moreover, when dispersed throughout another material to form a composite, these nanoparticles can influence how the composite functions as a whole.

For example, a polymer may lack electrical conductivity, but by mixing in a small quantity of nanoparticles which conduct electric current well, the polymer can become electrically conductive, or conversely, enhance insulation as needed.

Properties that can be added or removed or merely enhanced include:

· chemical resistance

· electromagnetic properties

· thermal conductivity

· abrasion resistance

· electrical conductivity

· mechanical strength

· antibacterial properties

· ultra-violet protection

This can be achieved without losing any of the polymer’s original properties, as nanomaterials are influential at an exceptionally low percentage of the total weight/volume.

This is because the nanoparticles’ tiny size gives them a huge surface area to weight ratio, meaning that 0.2 wt.% of nanoadditives can be an effective quantity. Furthermore, as such a small amount of nanomaterial can provide added strength, polymers designed with nanotechnology can actually be cheaper than those based only on conventional feedstocks.

While the integration of nanomaterials into polymers is not a widely known, the range of possibilities is limited only by imagination, making them a polymer force for change.

3. Protein-Based Biopolymers – Grown, Not Manufactured

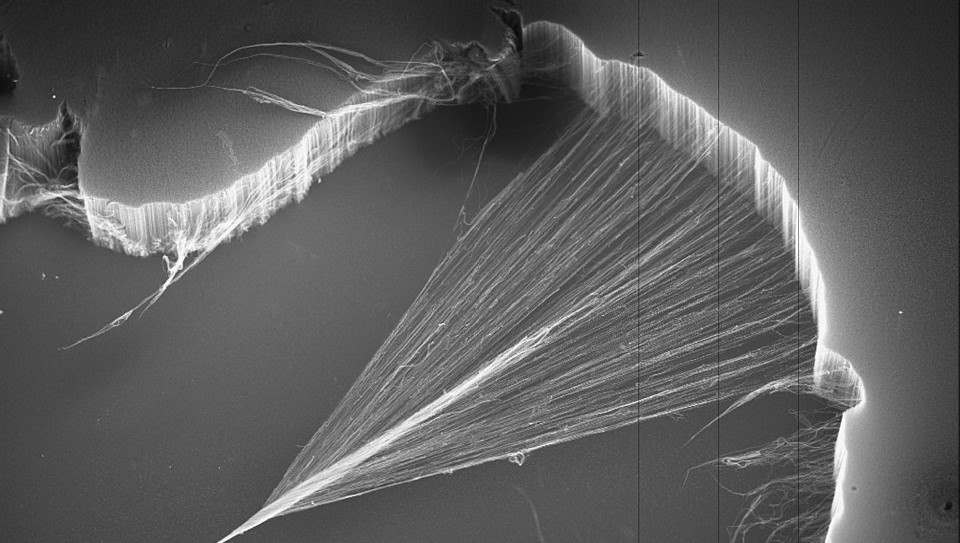

Nature has spent billions of years perfecting polymer structures such as silk, keratin, and collagen. But material scientists are now replicating and enhancing these protein-based biopolymers using precision fermentation and synthetic biology.

As production techniques scale, these materials may become viable replacements in mass-market products, including packaging and textiles.

Companies are already producing spider silk-inspired threads which are stronger than Kevlar, while researchers are developing biodegradable films for food packaging that mimic the skin of fruit. Not only are these polymers fully biodegradable and non-toxic, but some are even edible. In the coming decades, protein-based polymers could revolutionize textiles, agriculture, and medical devices, offering high performance with minimal environmental impact.

4. Self-Healing Polymers – Materials That Repair Themselves

Inspired by biological systems, self-healing polymers can repair microcracks or damage autonomously, often at room temperature. This innovation is a game-changer for industries where maintenance is costly or dangerous, such as aerospace, marine, or civil engineering.

Using embedded microcapsules or reversible chemical bonds, these polymers can restore their original structure after damage, significantly extending the lifespan of components. For example, imagine a polymer coating which can self-repair scratches or a car bumper that heals after a minor collision.

Additionally, nanoscale fillers, such as carbon nanotubes, graphene, and metal oxide nanoparticles, are being integrated into self-healing systems to enhance their mechanical strength, thermal stability, and responsiveness. Sometimes, these nanomaterials can act as triggers or sensors, detecting damage at the microscopic level or reacting to external influences such as moisture or light to initiate a more precise healing process.

With further progress in this field, self-healing polymers empowered by nanomaterials are expected to become standard in infrastructure, consumer goods, and robotics, with smarter, faster, and more durable performance than ever before.

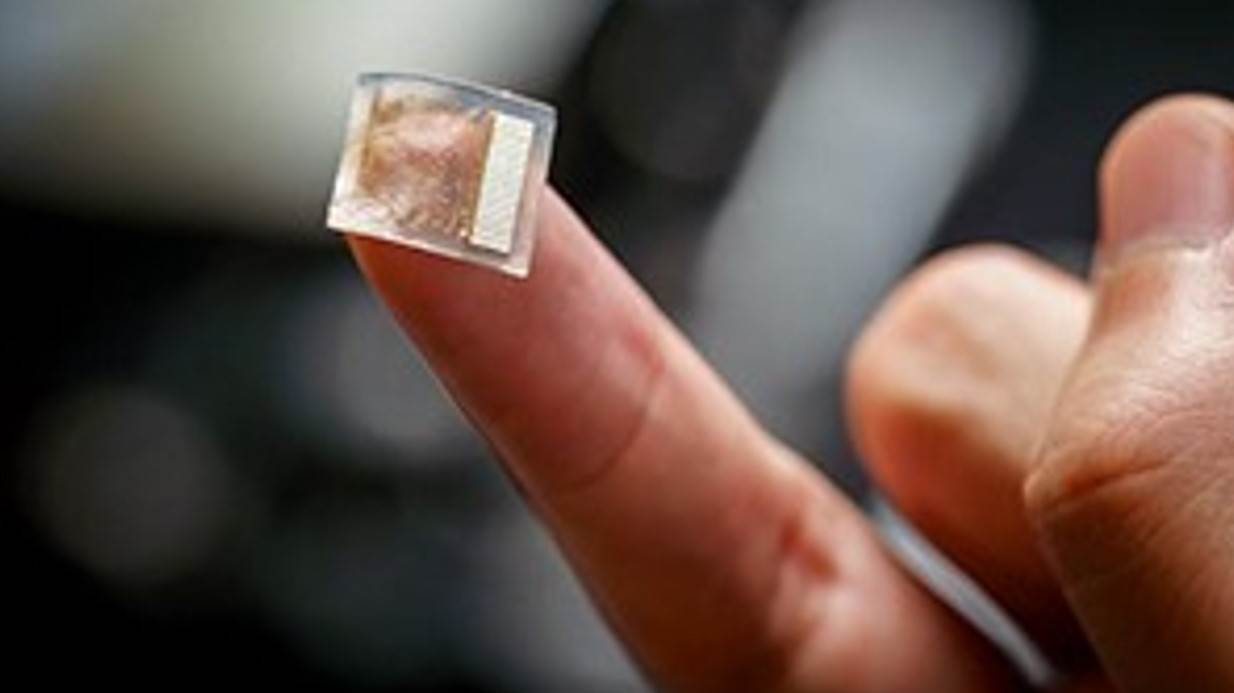

5. Conductive Biopolymers – The Future of Wearable Tech

The convergence of electronics and polymers has led to the rise of conductive biopolymers—organic materials that conduct electricity while remaining flexible, biocompatible, and even biodegradable. These materials are vital for the next generation of wearable and implantable electronics, including biosensors and smart bandages.

Furthermore, as they can interface with biological tissue more seamlessly than traditional metal components, they could even be developed further for medical applications and advanced electronics such as neural interfaces.

For this reason, it is expected that the conductive biopolymers’ market will grow as the IOT begins to be incorporated into fitness apparel, real-time health monitors, fashion accessories, and built in communication devices which are physically connected to the human body.

The Polymer Revolution Is Here

These five polymers—spanning renewable resources, nanotechnology, and bioengineering—represent a fundamental shift in how materials are designed and used. They are not just improvements; they are concepts come to life that will create entirely new industries to solve some of the planet’s most pressing problems.

In two decades, we may look back at today’s plastics the way we once viewed the making of silk: a revolution in its time, but primitive compared to what followed. Because whether it is saving the planet, enhancing human health, or building smarter infrastructure, the future for the polymer industry isn’t just bright—it’s transformative.

Related articles: 5 Polymers That Changed the World or Stronger Polymers Composites from a Nanoparticle Boost

Photo credit: Wikimedia, Freepik, Europeanhhm, Freepik, Linli Xu on Unsplash, Freepik, & Wikimedia