Smart Polymers That Harden Only When Needed

How on-demand polymerisation has become both possible and commercially viable.

Polymer production processes for coatings, composites, adhesives, and additive manufacturing all face the same recurring trade-off, where highly reactive systems offer performance, but at the cost of limited shelf life, strict handling requirements, and/or wasted raw materials.

For example, conventional cure-on-demand approaches typically rely on sensitive catalysts, thermal triggers, or tightly controlled processing windows — all of which add cost, energy use, and operational risk.

But the smart application of nanotechnology into polymers has introduced a fundamentally different strategy: instead of switching the catalyst on, the polymer’s building blocks themselves are switched off until activation. The result is a new class of latent polymer systems that remain stable during storage and transportation yet harden rapidly and precisely when triggered.

At the core of this advance is a photoswitchable olefin system based on the reversible transformation of the hydrocarbon quadricyclane into norbornadiene. In its quadricyclane form, the monomer is chemically “asleep” — resistant to polymerisation even in the presence of an active metathesis catalyst. Exposure to light or gentle heat reverses the molecular structure, restoring the reactive norbornadiene and allowing polymerisation to proceed immediately.

The discovery was made at the Ben-Gurion University of the Negev, and has now been published in the journal Nature Chemistry. “Instead of a 'sleeping' catalyst, we created 'sleeping' building blocks of the material itself,” says study lead Prof. Yossi Weizmann. “The mixture can sit quietly on the shelf for weeks and will snap together into a solid only when you shine light on it or warm it up. That kind of on-demand, light-driven curing could make industrial production, printing, and repair processes safer, simpler and more energy-efficient.”

This seemingly subtle chemical switch has major commercial implications, as it allows for formulations to be prepared, shipped, and stored in a ready-to-use liquid state without premature curing. Polymerisation occurs only when and where activation is applied.

Precision Curing Enabled by Nanotechnology

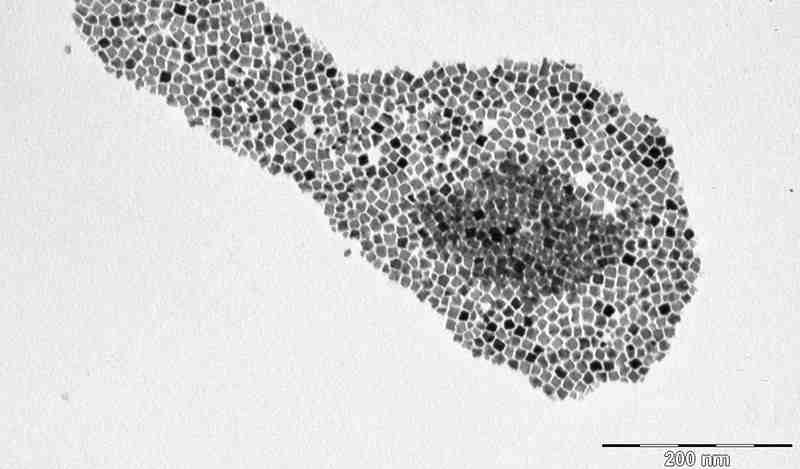

One of the most compelling aspects of the system is how activation can be localised. By incorporating gold nanoparticles that convert near-infrared light into heat, the nanomaterial researchers have demonstrated spatially selective curing. This means that only the illuminated regions of the polymer reach the activation temperature, while the surrounding material remains fluid and inactive.

At the heart of the new ‘sleeping state’ monomer are three key factors:

· Building blocks that can link together into long plastic-like chains.

· A standard industrial catalyst that drives the chain-forming reaction.

· Tiny gold nanoparticles that act as microscopic heaters when illuminated with near-infrared light.

For manufacturers, this opens the door to far more than simple curing control. Components with variable mechanical properties can be produced from a single formulation, enabling gradual transitions from soft to rigid regions within the same part.

Compared with conventional thermally or chemically initiated polymer systems, latent monomer architectures offer several practical benefits:

· Extended shelf life without refrigeration or inert atmospheres, reducing storage and transport costs.

· Lower energy input during curing, as activation relies on mild heating or targeted light exposure.

· Improved workplace safety by avoiding highly reactive or unstable initiators.

· Reduced waste from premature gelation or expired formulations.

These advantages directly address cost, reliability, and scalability — the key factors that most likely to restrict adoption of advanced polymer chemistries by manufacturers.

The technology even aligns well with production processes. In additive manufacturing, for example, latent monomers could remain printable for extended periods and be cured layer-by-layer with exceptional spatial accuracy. In coatings and repair applications, materials could be applied without time pressure and hardened only after precise positioning.

It is this kind of application of nanotechnology that is quietly revolutionising the polymer industry. The application of nanomaterials into polymers has already solved numerous challenges, allowing for UV-protective coatings, fast curing of epoxy resin floorings, polypropylene with antimicrobial surfaces, or crack-resistant paints.

Related articles: Nanotech for Industry or Boosting Strength, Cutting Costs: Nanotech in Green Polymers

Now polymer researchers have used gold nanoparticles to enable the on-demand curing of a polymer. A discovery which may help other polymer manufacturers to wonder how their processes and products could be adapted with nanotechnology to provide unique selling points or to create cost savings.

As Nir Lemcoff, one of the study’s lead authors, concludes, “This work demonstrates a new way of thinking about a general problem in polymer science. Hopefully, it will inspire scientists [and polymer producers] to look at the challenges in their own work with a fresh point of view.”

POLYMER NANO CENTRUM helps businesses turn polymer ideas into market-ready products faster and with less risk. By combining applied research, advanced testing and real industrial experience, the centre supports companies at every stage of product design.

Businesses gain access to expert guidance on material selection, nano-additives, processing methods and performance optimisation. This reduces development costs, shortens time to market and improves product reliability. POLYMER NANO CENTRUM (who sponsor this website) also helps firms meet regulatory and sustainability requirements, giving them a competitive edge. For SMEs especially, it acts as an innovation partner that bridges the gap between laboratory research and profitable commercial production.

Photo credit: Flickr, Jakub Zerdzicki on Pexels, & Public Domain Pictures