Nanomaterials Used to Reinforce Thermoset Plastics

Nanotechnology researchers from Madrid have developed a new method for strengthening polymers with carbon nanotubes.

In many ways, thermoset plastics are superior to thermoplastics.

Despite being more brittle, they often have a stronger resistance to impact and mechanical stress. For this reason, thermoset plastics, like epoxy resin, silicone, and melamine, are frequently utilised in construction. To improve on this strength, chemical engineers use reinforcing elements like carbon fibres to make these polymers even stronger. Here they can be found in the production of extremely durable, but difficult to recycle, items like sports equipment and motorbike helmets.

But now a team of nanomaterial scientists from the not-for-profit IMDEA Nanociencia research institute in Madrid are looking at ways to improve polymers, such a thermoset plastics, through the inclusion of carbon nanotubes.

While the nanotechnology behind the discovery is highly advanced, the premise is simply a new way to combine the innate strength of a carbon nanotube with a polymer molecule to create a stronger plastic.

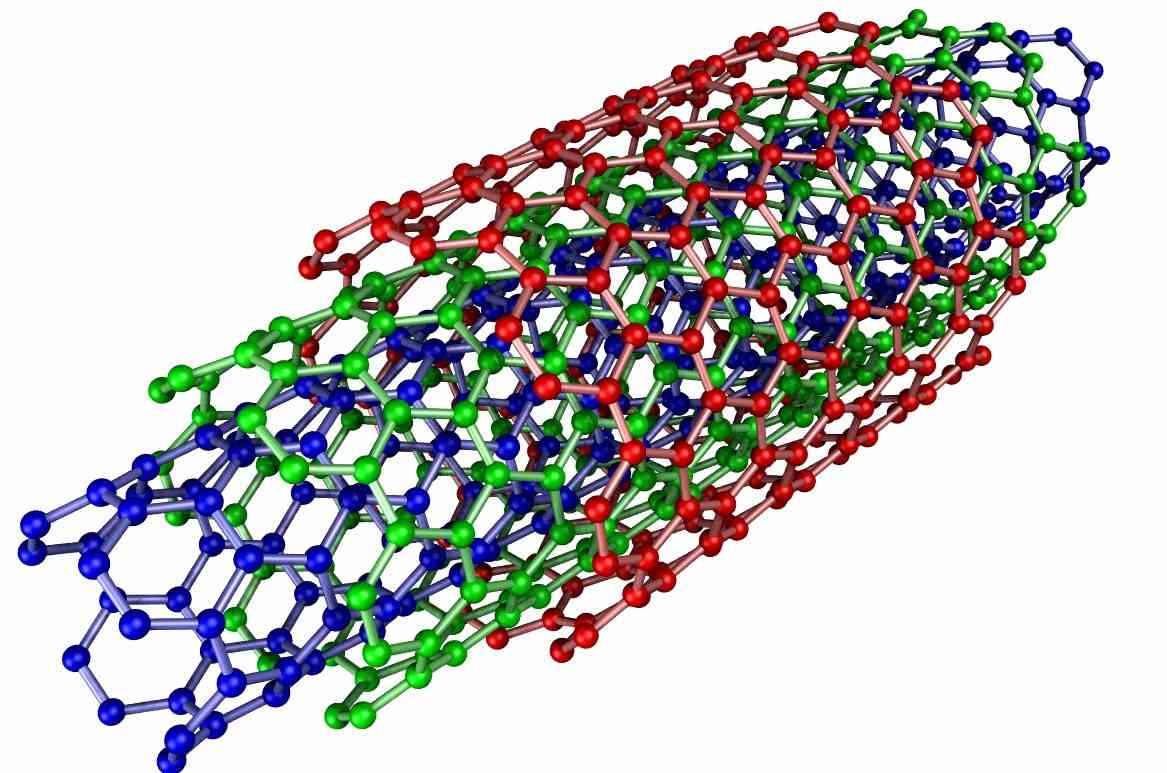

Specifically, the press release on the breakthrough describes it as, “… the use of a derivative of carbon nanotubes that have a ring molecule around them - mechanically interlocked carbon nanotubes MINTs. The ring molecules are attached to the carbon nanotube mechanically, not chemically, so the bond between the two is very strong, but at the same time allows a certain movement of the molecule along the nanotube. The researchers have equipped the ring with two anchor points … so that they covalently bond with the polymers. In this way, the nanotube becomes a structural part of the polymer network.”

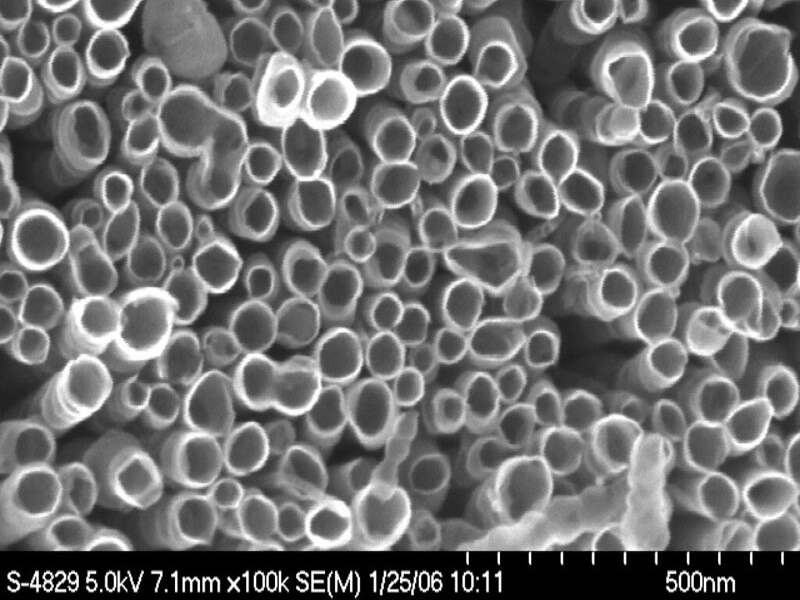

In essence, carbon nanotubes are graphene sheets rolled into a tube shape. Covalent bonds can be used to directly link a nanotube with another molecule, however doing so weakens the tube, as it adds flaws and potential breakpoints. However, the researchers’ innovative approach integrates the nanotubes into the polymer lattice so that it can maintain all of its desirable characteristics while still optimising the load transfer from the matrix to the reinforcement.

This combination of nanotube with reinforced ring has now been proven as an effective strengthening agent in polymers.

As the study states, “Adding only 1% nanotubes by weight to the polymer mixture achieves a 77% improvement in Young's modulus, and a 100% improvement in tensile strength. Remarkably, the mechanical properties of this reinforced plastic remain intact after being melted down and recycled up to 4 times.”

Such is the efficiency of the bond created with this method, that the plastic does not become stronger by adding more nanotubes because doing so would mean that they would clump together and become less effective. Instead, the covalent connection between the polymer and the nanotubes is already at an optimal point.

The minuscule size of nanomaterials also allows for uniform dispersion throughout the polymer, creating a reinforced material with consistent, enhanced performance. Moreover, the high surface area-to-volume ratio of nanomaterials enables strong interfacial interactions with the polymer, further contributing to the composite's mechanical integrity. This synergistic integration of nanomaterials and polymers opens the door to a new generation of advanced, high-performance materials with applications spanning aerospace, automotive, packaging, and beyond.

It is a discovery which offers a wealth of advantages with increasing appeal across a range of industries. This is because they can dramatically improve tensile strength, impact resistance, thermal stability, and barrier properties - all while maintaining the lightweight and mouldable nature of the original polymer.

As well as being recyclable, environmental advantages can also be gained from using nanomaterial-strengthened polymers. As Emilio Pérez, who led the research, explains, “Producing lighter structures, such as cars, planes, etc., would mean considerable fuel savings.”

However, even manufacturers of simpler polymers can still gain commercial advantages from using nanomaterial additives. For example, even an everyday plastic, such as polycarbonate, can be made stronger, meaning that less raw material is needed to make it – drastically lowering feedstock costs.

Nanomaterials as a raw material can also provide unique selling points, for example, plastic food packaging can be given chemical sensors that detect the gases released from aging food. Polymers can also be made more scratch resistant, be made electro-conductive, or provided with UV-protective properties.

Since 2016, POLYMER NANO CENTRUM (which hosts this webpage) has been providing its clients with nanotechnology that give these unique selling points or economic savings.

If you would like to know more about how nanomaterial additives could improve your polymer products, then please visit POLYMER NANO CENTRUM, and ask about their off-the-shelf products or bespoke manufacturing solutions.

Photo credit: Stocksnap, Polocatalog, Flickr, Wikimedia, & Freepik