Nanofibres in Industry: A Real Promise but Slow Adoption

Why aren't more manufacturers using nanofibres as an industrial feedstock?

Manufacturers of specialised polymer products are under constant pressure to deliver more: lighter materials, better performance, longer lifetimes, and increasingly, sustainability. Over the past two decades, nanomaterials – and nanofibres in particular – have been presented as a solution to many of these challenges. Yet despite extensive research and thousands of academic papers, nanofibres remain rare in mainstream industrial polymer products.

“After more than 25 years of intensive research,” Dr Noopur Jain, a material science specialist notes, “nanofibers remain scientifically promising but industrially constrained.”

A recent analysis of this issue has now been published in Frontiers in Nanotechnology, taking a clear look at the gap between nanofibres’ promise and the reality of their use in industry. Its message is reassuring for manufacturers: nanofibres are not a failed technology, but their commercial success depends more on manufacturing practicality and guidance.

What are Nanofibres, in Simple Terms?

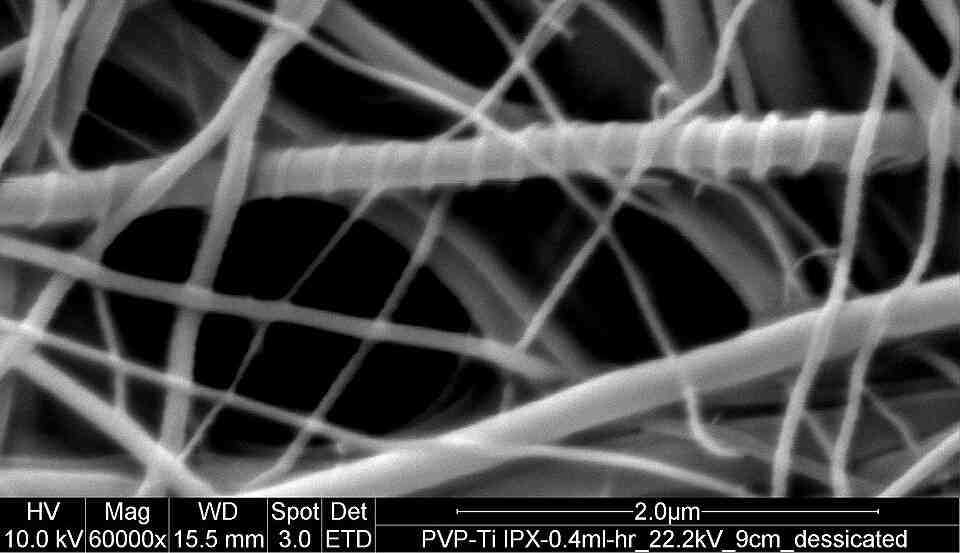

Nanofibres are extremely thin polymer fibres, typically thousands of times thinner than a human hair. Their value lies not in their size alone, but in what that size enables. Because nanofibres have a very high surface area relative to their weight and volume, they can dramatically influence how a conventional raw material behaves. When incorporated correctly, they can improve filtration efficiency, surface functionality, mechanical reinforcement, or a material’s interaction with liquids and gases. For example, they can improve a polymer’s scratch resistance, add UV protection, and/or provide electrical or thermal conductivity.

For manufacturers unfamiliar with nanomaterials, it is important to stress that nanofibres are not a replacement for conventional polymers. Instead, they act as a functional layer or reinforcing element that upgrades performance without fundamentally changing the base material.

Why Haven’t Nanofibres gone Mainstream?

According to the Frontiers article, written by prominent nanotechnology specialists from the Czech Republic’s Center of Materials and Nanotechnologies and the Central European Institute of Technology, the main barriers have little to do with whether nanofibres work as countless research in laboratory settings has proven their benefits. Instead, the problem lies in scaling those benefits to industrial volumes at acceptable cost and reliability.

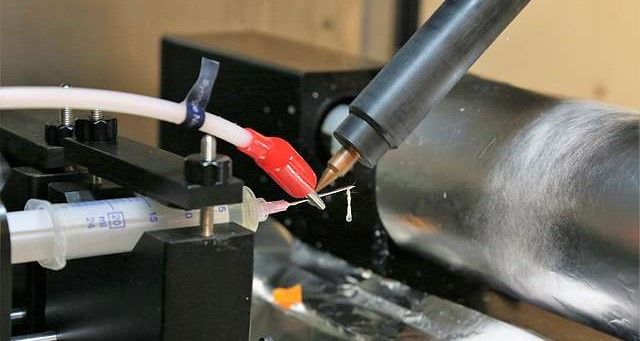

The most established production method, electrospinning, can produce very fine and well-controlled fibres, but it struggles with throughput. This means that producing square metres of nanofibre material is straightforward; producing millions of them consistently is not. This creates a cost gap that many manufacturers cannot justify unless the performance improvement is truly decisive.

The article highlights three recurring industrial concerns:

· Limited production speed compared with conventional polymer processing.

· Challenges in maintaining uniform quality at scale.

· Difficulty integrating nanofibre steps into existing production lines.

Crucially, these are engineering and business problems, not scientific ones.

Where Nanofibres already make Commercial Sense

Despite these challenges, nanofibres are already finding their way into industrial products where performance outweighs cost sensitivity.

The article emphasises that success tends to come where nanofibres are used selectively, not everywhere. Adding that even a very thin nanofibre layer can significantly improve a polymer's performance, making the economics easier to justify. Advanced coatings, functional textiles, and specialised composite layers, are just a few examples of where nanofibres add value to products.

A More Realistic Outlook for Nanofibres in Industry

Crucially, the authors argue that nanofibre development must now be driven by manufacturing targets rather than laboratory perfection. For polymer producers, this means focusing on “good enough” performance that can be produced reliably, rather than chasing idealised material properties that never leave the lab.

Many nanotechnology insiders have also highlighted the growing range of “off-the-shelf” nanomaterial additives that can be easily sourced and mixed into existing polymer products without the need for intensive development or having to alter production processes and machinery.

What Does the Study mean for Polymer Manufacturers?

For manufacturers considering product upgrades, nanofibres should be viewed as a strategic option rather than an unnecessary gamble. They are most suitable in situations where a specific raw material property can be added or enhanced to provide extra value or to meet the needs of an individual customer.

The key takeaway from academic article is that nanofibres are not waiting for a scientific breakthrough but are instead largely waiting to be accurately deployed in industry. This means that manufacturers who engage in their application early, especially through cooperation with nanomaterial specialists, will be best placed to turn the long-standing promise of nanotechnology into a competitive advantage.

To learn more about applying nanotechnology into everyday products such as coatings, resins, or plastics, consider contacting the experts at POLYMER NANO CENTRUM.

POLYMER NANO CENTRUM (who host this webpage) is a Czech private technology company specialising in the research, development, and industrial application of nanotechnologies in polymer materials. Founded in 2016, the company focuses on enhancing plastics and composites by incorporating nanomaterials to improve mechanical strength, durability, thermal resistance, and electrical properties.

Uniquely, the company operates its own research and testing facilities in the Czech Republic and works closely with industrial partners to bring laboratory innovations into real-world production. Its solutions are used in sectors such as automotive, construction, electronics, and advanced industrial manufacturing, positioning the company as a bridge between nanoscience and commercial polymer applications.

Photo credit: Picryl, Wikipedia, Wikimedia, & NANO CHEMI GROUP