Nanocomposites Create Antimicrobial Coating for Touchscreens

Nanotechnology provides a durable yet flexible, antimicrobial, glass-like coating for touchscreens.

With the growing popularity of touchscreens has come an increased risk of spreading bacteria and microbes from finger to screen to finger. Moreover, modern technology has moved beyond personal mobile phones and tablets, to now include touchscreen devices at supermarkets, restaurants, ATMs, and airport check-in kiosks—each one contaminated by hundreds if not thousands of users every day.

Following the COVID pandemic, reducing the number of bacteria, viruses, and microorganisms present on these screens has become a matter of government importance, especially in health-sensitive places, such as hospitals and food preparation areas.

But a study by nanotechnology researchers from the Chinese Academy of Sciences may now have found a solution by creating a flexible, glass-like, nanocomposite coating with exceptional antimicrobial properties.

Applied by simple spray techniques, the coating is, according to the study which has been published in the journal Advanced Materials, “… a seamless integration of multiple high-performance properties: potent and durable antibacterial activity (>99.99%), excellent biocompatibility, polymer-like flexibility, glass-like damage tolerance, and high transparency.”

Antimicrobial Performance Without Compromising Functionality

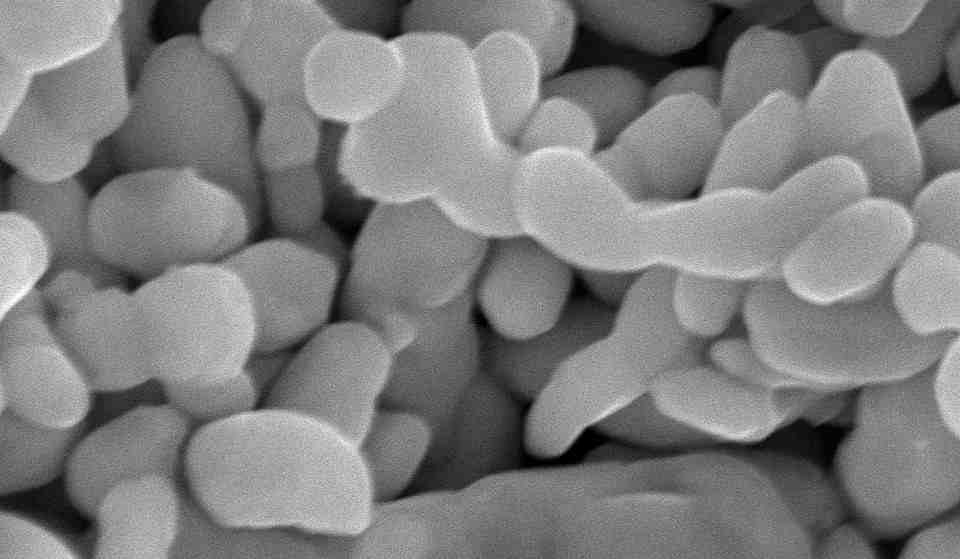

At the core of the technology is a solution-processable precursor where silver nanoparticles nucleate, stabilise, and anchor themselves to form a dense, transparent nanocomposite layer after curing. This can be done through a single coordinated chemical process, as opposed to combining preformed nanoparticles into a matrix where they invariably clump together and scatter light.

Significantly, the nanocomposite coating offers numerous qualities which make it practical for use in heavy-use touchscreens. As a report in the nanotechnology journal Nanowerk, highlights, the nanocomposite provides “… optical transparency nearly matching bare glass, hardness seven times greater than common polymers, and flexibility sufficient to survive 3000 folding cycles at a 1.5 mm radius, tight enough for the hinges of current foldable smartphones.” Adding that, “The coating cures at just 80 °C, making it compatible with heat-sensitive plastic substrates, and the researchers project functional lifespans extending beyond two years under typical use conditions.”

Unlike conventional hard coatings, this material retains a degree of flexibility which allows it to conform to a wide range of substrates, including plastics, metals, and flexible polymer films, without cracking or delaminating. Its transparency and smoothness also makes the nanotechnology highly suitable for commercial use, so it can easily be adopted for polymer-rich applications such as medical devices, touch interfaces, and wearable technologies.

Why This Matters for Manufacturers

From a business viewpoint, the work highlights several strategically key factors:

· A shift from complex deposition methods to spray-based, scalable processing without the need for major alterations to existing coating lines.

· Integration of antimicrobial functionality without sacrificing optical clarity or mechanical integrity.

· The growing role of hybrid polymer–inorganic nanocomposites in functional surface design.

While challenges remain, particularly around long-term wear, cleaning resistance, and regulatory approval in medical contexts, the underlying nanomaterial design has clearly been created with scalability in mind. This opens pathways for use in hospitals, public transport interiors, consumer electronics housings, and high-touch polymer components.

With demand for hygienic, multifunctional surfaces growing, polymer-based nanocomposite coatings are likely to play a central role in meeting market need—moving beyond experimental novelty to commercial utility.

This specific transition from academic proof-of-concept to useable coating also underlines the importance of designing new materials with manufacturing constraints considered from the outset.

Bringing Antimicrobial Nanotechnology to Market

Today, nanotechnology specialist firms are on hand to assist manufacturers with every stage of the process. Showing how to assess a problem/market need, design a material with nanotechnology to resolve the issue, and then guide a product through the streamlined steps of theoretical testing, sample testing, upscaling, regulatory sign-off, production, and commercialisation.

One such business is POLYMER NANO CENTRUM; a specialised research and innovation centre focused on the development, testing, and commercialisation of advanced polymer and nanocomposite materials. Working at the intersection of academic research and industrial application, the centre supports manufacturers and technology developers in translating laboratory-scale concepts into scalable, market-ready solutions. With expertise spanning material design, nanotechnology integration, process optimisation, and regulatory considerations, POLYMER NANO CENTRUM (who support this webpage) helps bridge the gap between cutting-edge materials science and real-world manufacturing requirements.

The nanotechnology breakthrough made at the Chinese Academy of Sciences demonstrates the real potential of polymer-based nanocomposite coatings to address a real-world problem—keeping high-touch surfaces hygienic without compromising functionality.

For manufacturers, discoveries like this are so much more than scientific achievements, instead they are proof-of-concept for a new generation of multifunctional coatings that can be implemented safely, efficiently, and at scale. With companies like POLYMER NANO CENTRUM providing guidance and expertise, the pathway from research to market-ready solution has never been clearer, signalling a future where touchscreens, medical devices, and other polymers that are not only high-performing but also hygienically safe.

To learn more about how nanotechnology can improve everyday polymer products, resins, and coatings, visit POLYMER NANO CENTRUM or contact info@polymernanocentrum.cz

Photo credit: Freepik, Intenza Fitness on Unsplash, Prostooleh, & Wikimedia