Beetroot-Nanotech for Antimicrobial Action in Polypropylene

When nanomaterial science finds a root to meet polymer manufacturing need.

Recent research has pointed to an unexpected but commercially relevant development for the plastic sector: beetroot extract can be used to produce highly effective antimicrobial nanocomposites. While the science itself is notable, the real significance lies in what this approach could mean for polymer manufacturers striving to gain a competitive advantage beyond price reductions.

Antimicrobial polymers are widely used across packaging, textiles, healthcare surfaces, and consumer goods, yet they remain cost-sensitive products. Traditional nanoparticle synthesis relies on chemical reducing agents that are not only expensive, but also energy-intensive and increasingly exposed to regulatory scrutiny. Against this backdrop, greener synthesis routes are attracting attention not just from researchers, but from manufacturers under pressure to reduce both costs and environmental impact.

From Laboratory Novelty to Industrial Relevance

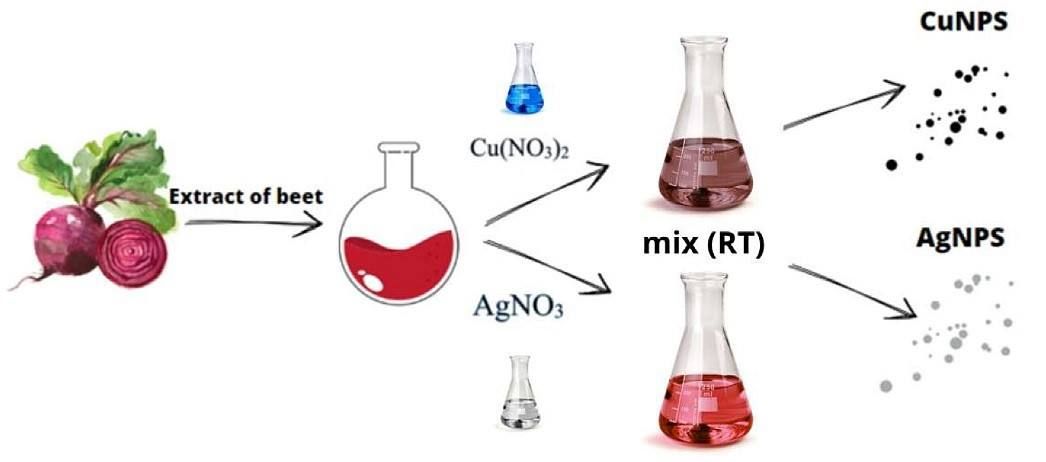

The study compared copper and silver nanoparticles produced via conventional chemical synthesis with those produced using beetroot extract as a natural reducing and stabilising agent. These nanoparticles were then incorporated into polypropylene, a widely used and commercially important polymer.

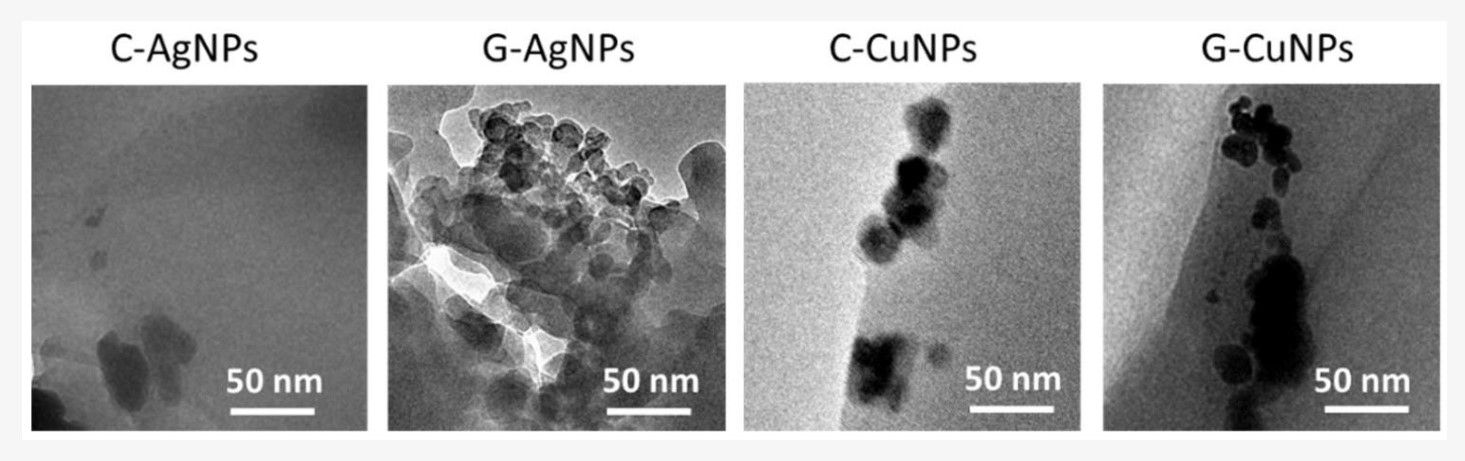

Crucially, the beetroot-based copper nanoparticles demonstrated superior antimicrobial performance. This was not simply a marginal improvement: the green-synthesised particles were smaller, better dispersed within the polymer matrix and more effective against both bacteria and fungi.

As the study’s authors explain in the peer-reviewed journal Materials, “Copper nanoparticles synthesized using beetroot extract exhibited particularly enhanced fungicidal and bactericidal properties, demonstrating the effectiveness of plant-based reducing agents in producing functional nanostructures.” Adding that, “To further evaluate potential applications, the green-synthesized nanoparticles were incorporated into a polypropylene matrix, confirming their integrity and activity within the composite system.”

Why Beetroot Matters for Cost and Supply Chains

Plant-based synthesis methods replace multiple chemical inputs with a single, low-cost biomass feedstock. Beetroot extract, in particular, offers several advantages that are commercially relevant:

· It is inexpensive, widely available, and already part of established agricultural supply chains.

· It reduces dependence on specialist chemical reagents, which can suffer volatile pricing.

· It lowers the waste-handling and compliance costs associated with hazardous substances.

For SMEs producing antimicrobial masterbatches or finished polymer products, these factors directly affect margins. Lower synthesis costs combined with improved antimicrobial efficacy create room for either price competitiveness or premium positioning, depending on market strategy.

Copper Regains Ground Against Silver

Silver has long dominated antimicrobial applications, but its price volatility and growing regulatory pressure are forcing producers to reconsider alternatives. Copper is significantly cheaper and more abundant but has often been seen as less effective or harder to stabilise in polymers.

“Once embedded in polypropylene, silver nanoparticles (regardless of synthesis route) showed a stronger tendency to agglomerate,” notes Dr Noopur Jain, a specialist in nanomaterial research. “Copper nanoparticles were generally better dispersed, particularly those produced via green synthesis, making them more accessible at the polymer-microbe interface.”

This research suggests that synthesis route can be as important as material choice. Green-synthesised copper nanoparticles not only matched but exceeded the antimicrobial performance of their chemically synthesised counterparts, challenging the assumption that higher-cost metals are inherently superior.

Related articles: Graphene Coatings: Sustainable Antifouling for Marine Surfaces or Nanotech for Industry

For manufacturers, this opens the door to reformulating existing products with lower raw-material exposure while maintaining or improving performance.

Moreover, sustainability messaging is becoming a decisive factor in procurement, particularly in European markets. Using plant-derived synthesis routes strengthens environmental credentials without requiring major changes to downstream processing. Polypropylene remains the base polymer, existing compounding infrastructure can still be used, and no radical retooling is required.

This makes green nanocomposites attractive as an incremental innovation as it offers low disruption, measurable benefits, and a clear story for customers increasingly focused on ESG metrics.

What Comes Next for Commercialisation?

While further work is needed on scale-up, long-term stability, and recyclability, the direction is clear. Green synthesis methods for nanomaterial feedstocks are moving beyond academic experimentation and into economically meaningful territory. For companies operating in antimicrobial polymers, especially SMEs, this is a signal worth watching closely.

The beetroot-based approach illustrates a broader trend: competitive advantage in advanced materials may come less from exotic chemistry and more from smarter, cheaper roots.

Photo credit: Materials, Materials, Materials, & Rawpixel on Freepik